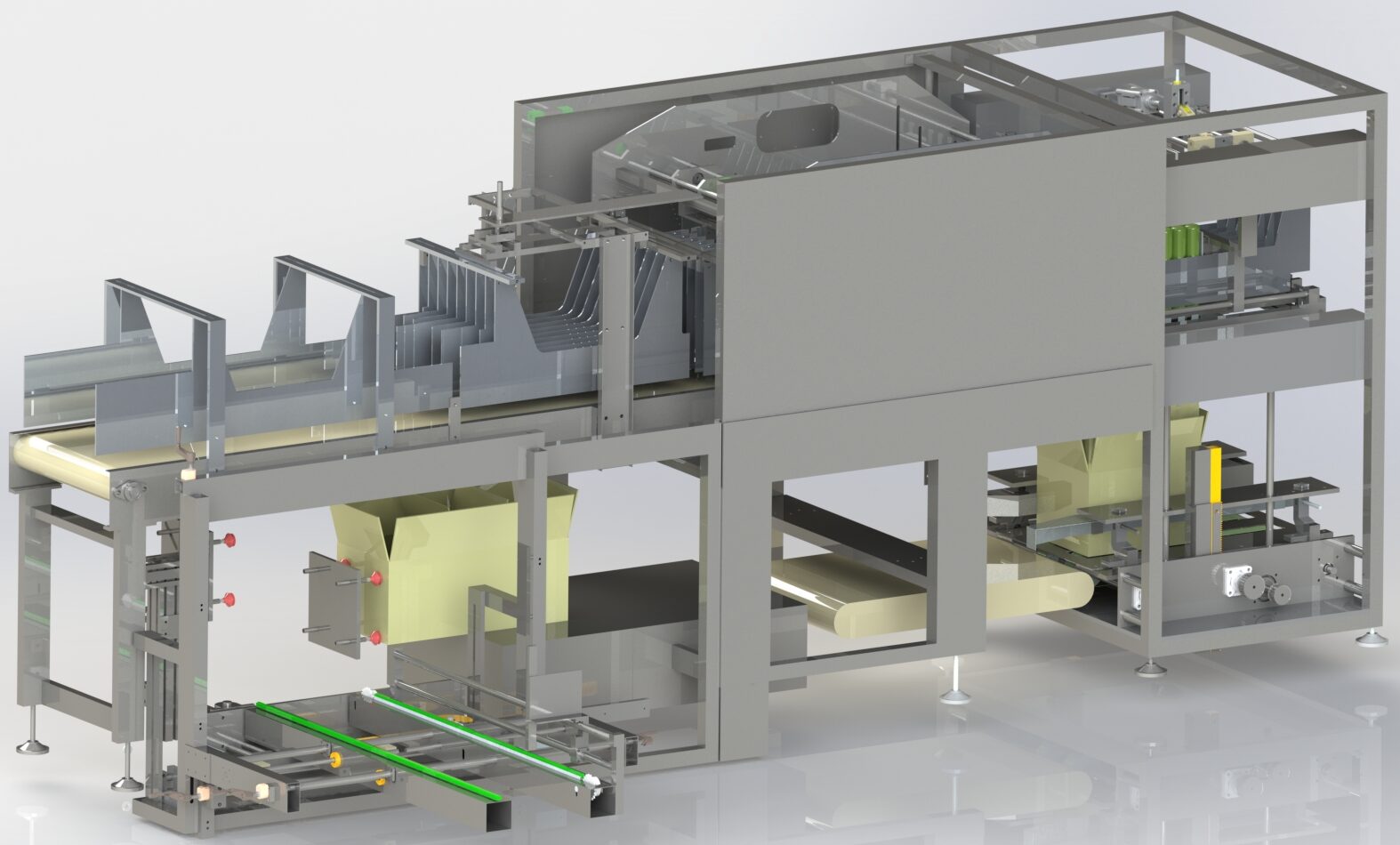

Sora Machine

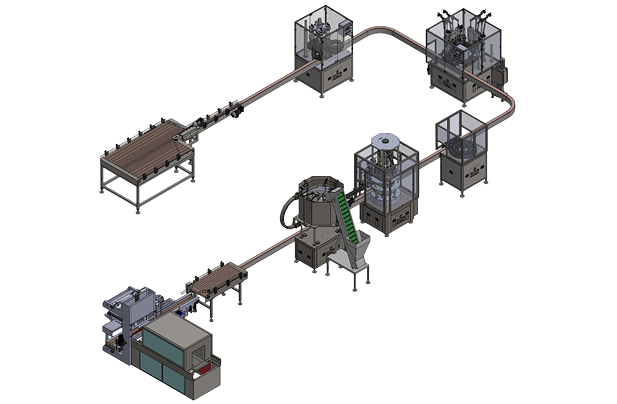

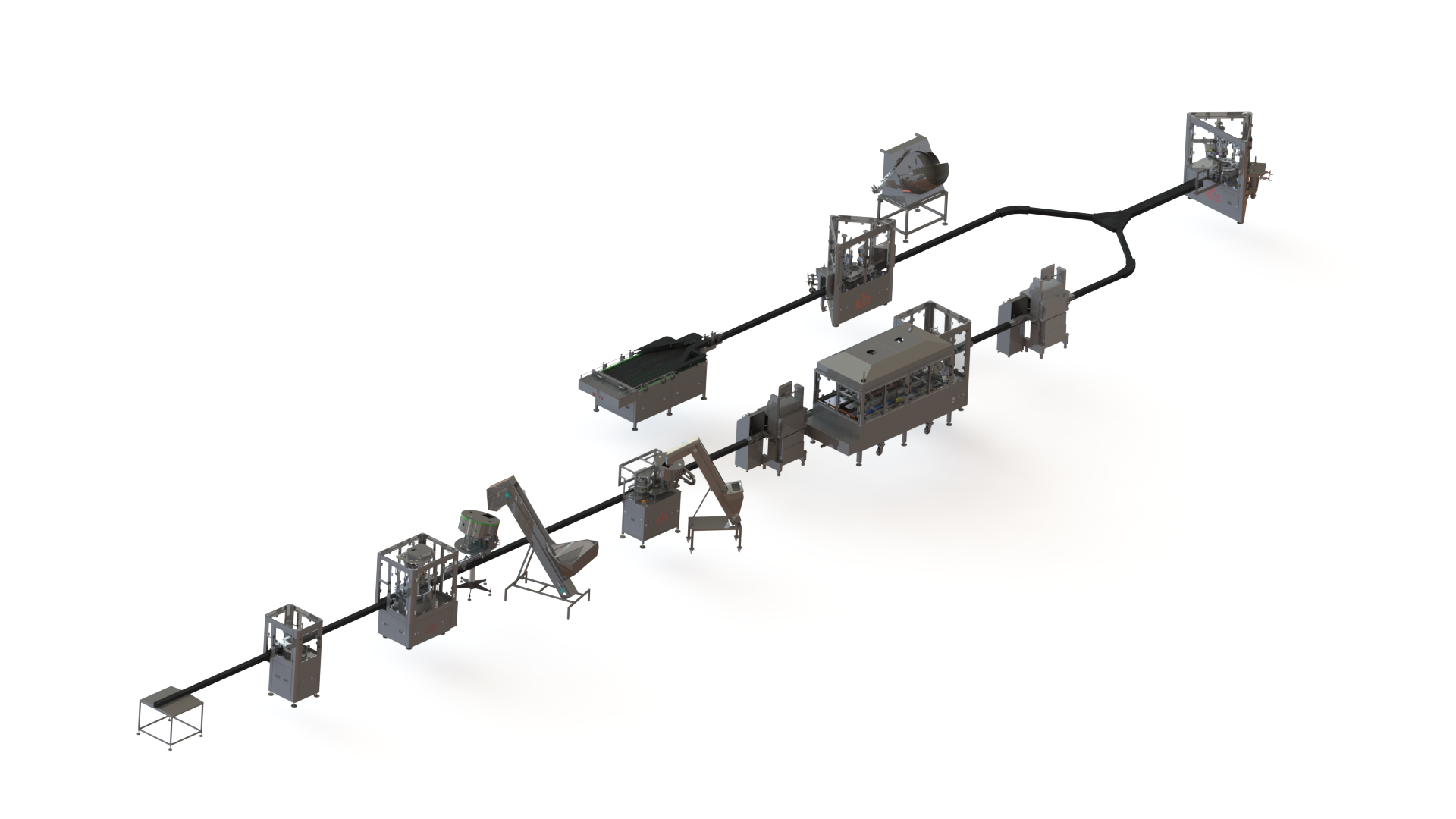

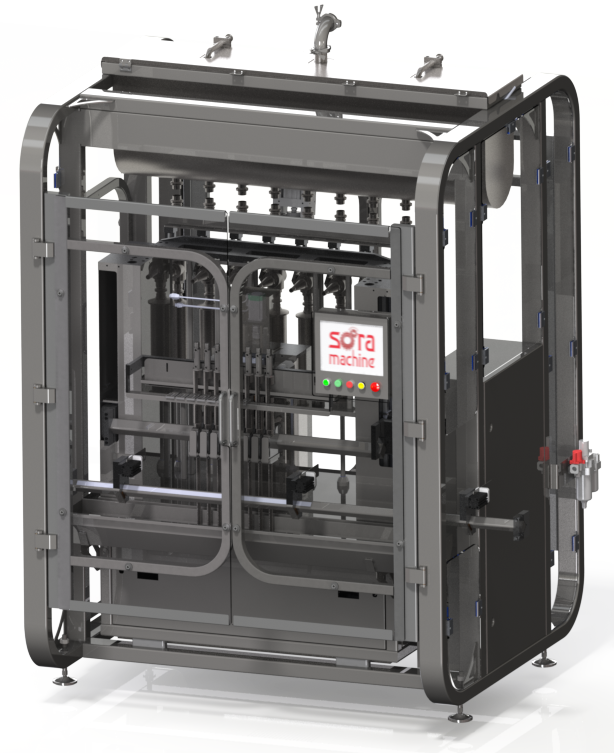

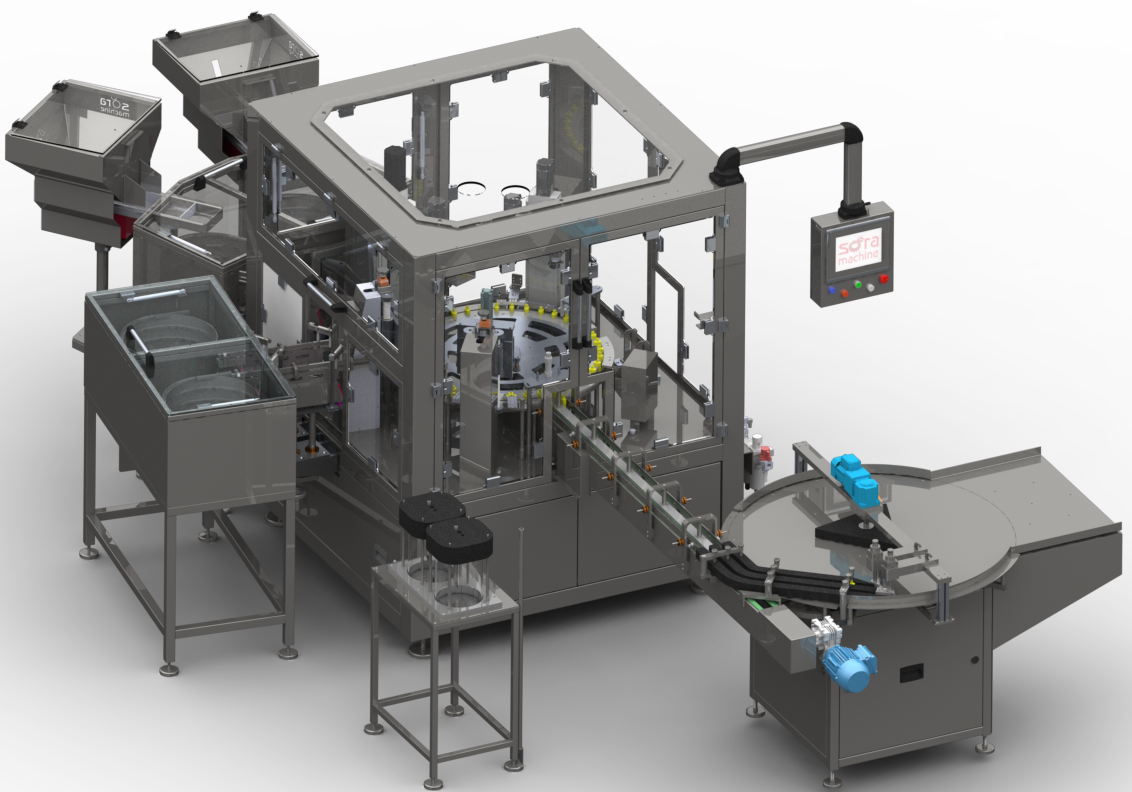

Sora Machine was founded in 1981 by Mr. Yılmaz Kesme, the father of Barış Kesme, CEO of Sora Group. Sora Machine is the first manufacturer of aerosol product machines in Turkey, and has continued to offer innovative solutions to its customers using the most recent technology.

With over 40 years of experience in designing and manufacturing machinery, we have established a reputation for our expertise. Our team is able to promptly develop new projects for future products and offer high-quality services in various sectors. We are dedicated to providing flexible, timely responses to our customer’s needs. Quality is at the forefront of everything we do at Sora Machine, and it plays a crucial role in all of our business processes. Our goal is to systematically produce faster units while maintaining the highest level of quality. In the 21st century, our focus is on maximizing production without compromising on quality.

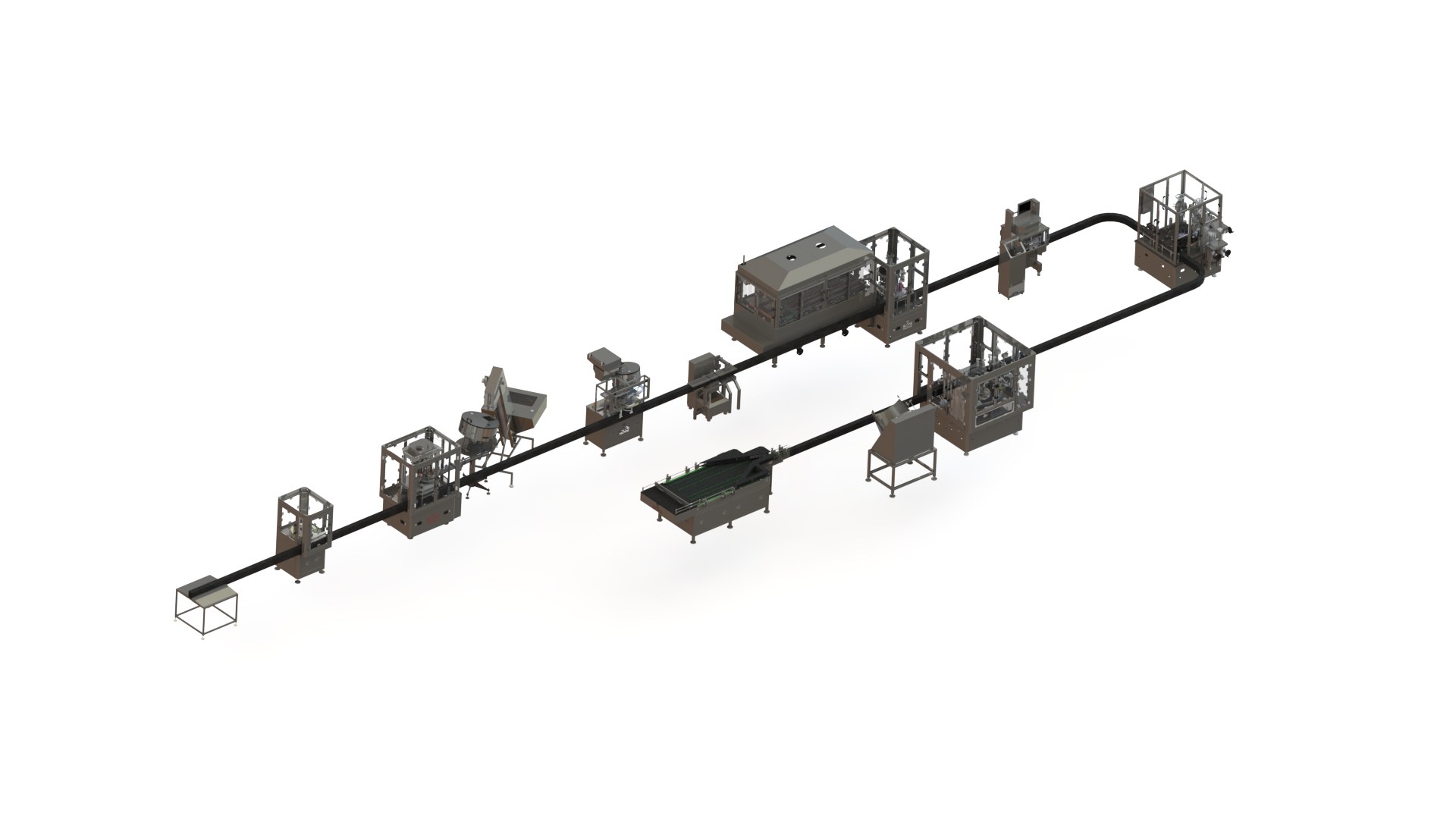

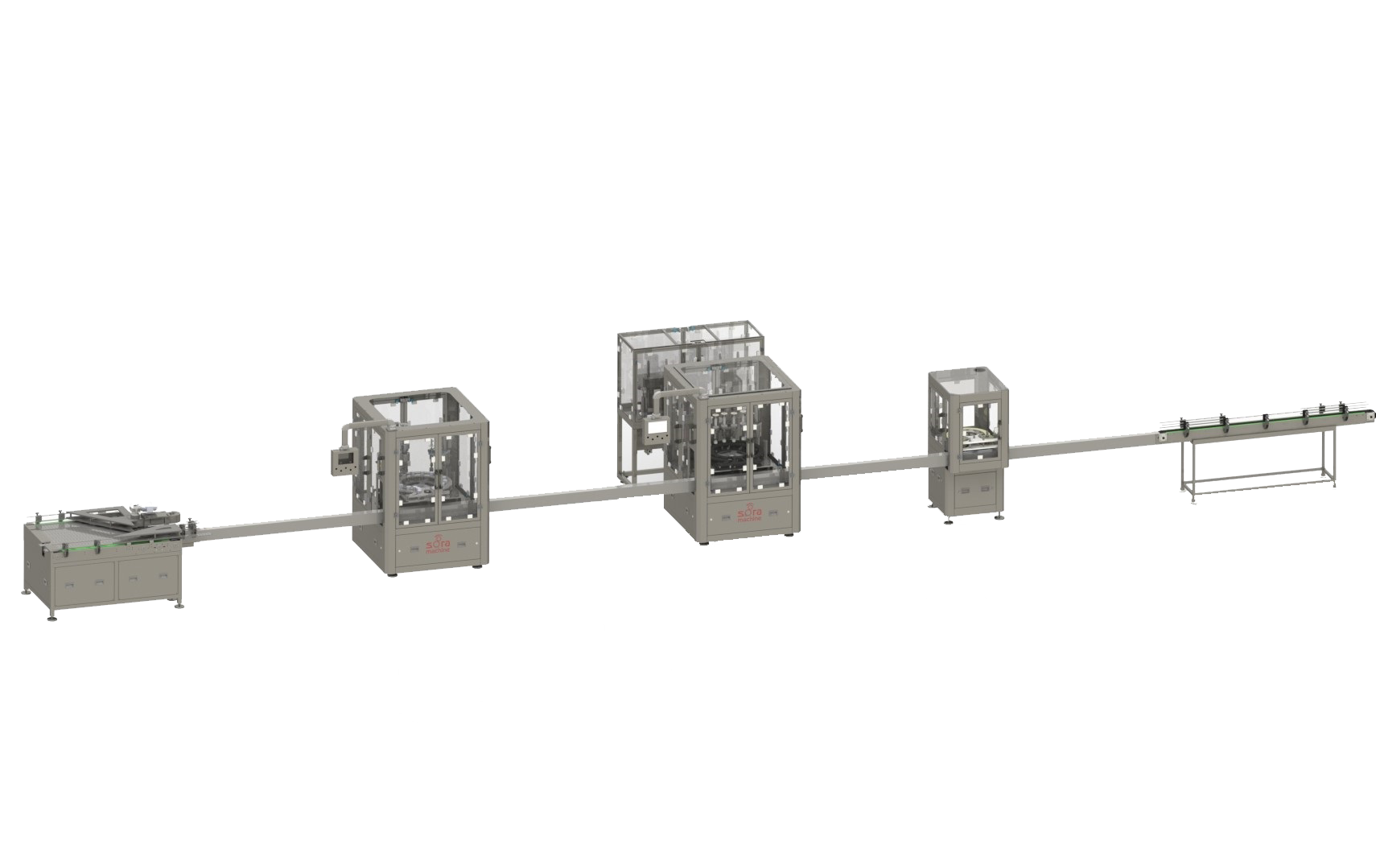

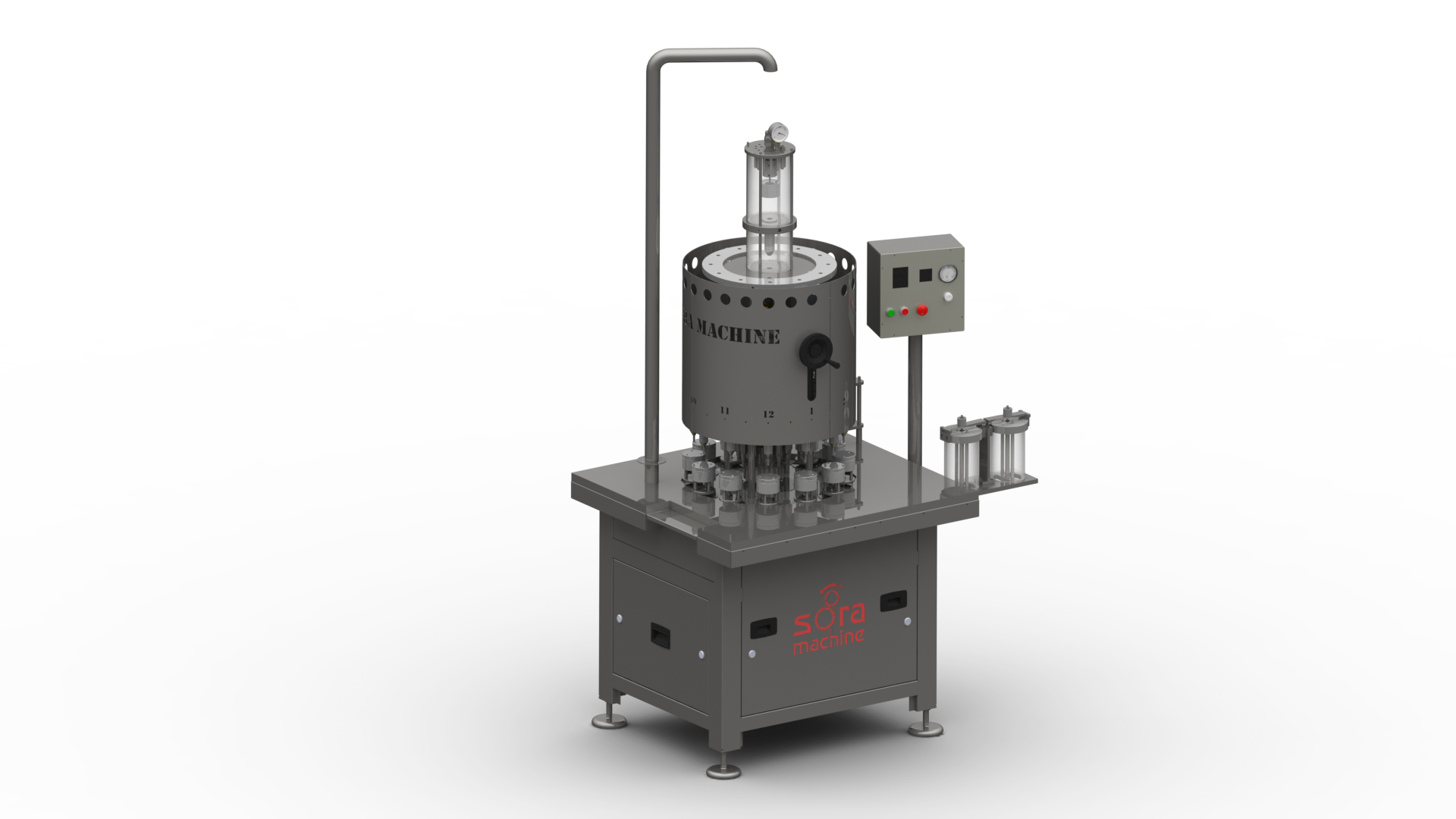

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

- Product contact parts: AISI 316 or AISI 304 (quoted based on AISI 304)

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Scrolls, change parts and plastic covers on guide rails are anti-static

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

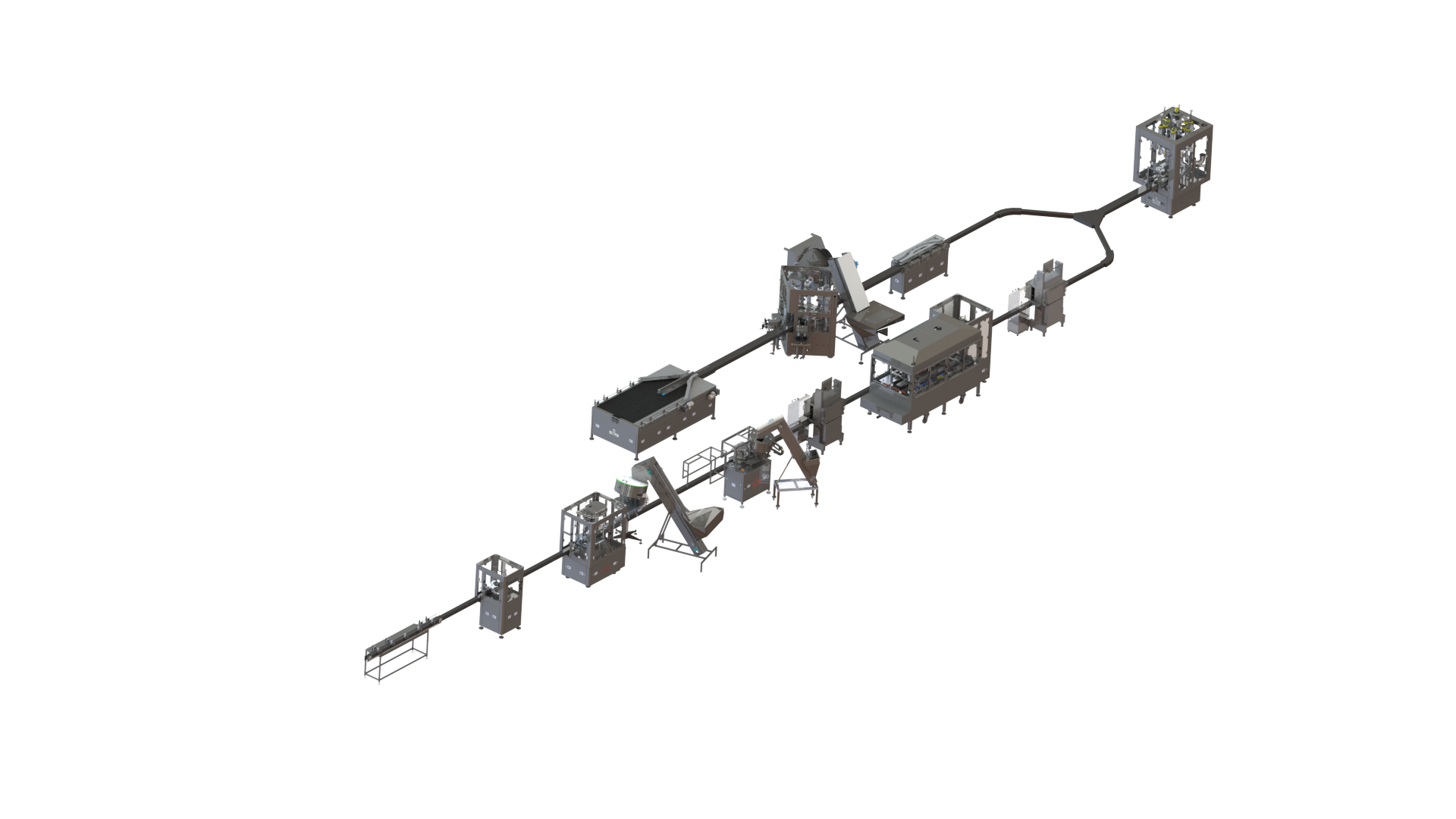

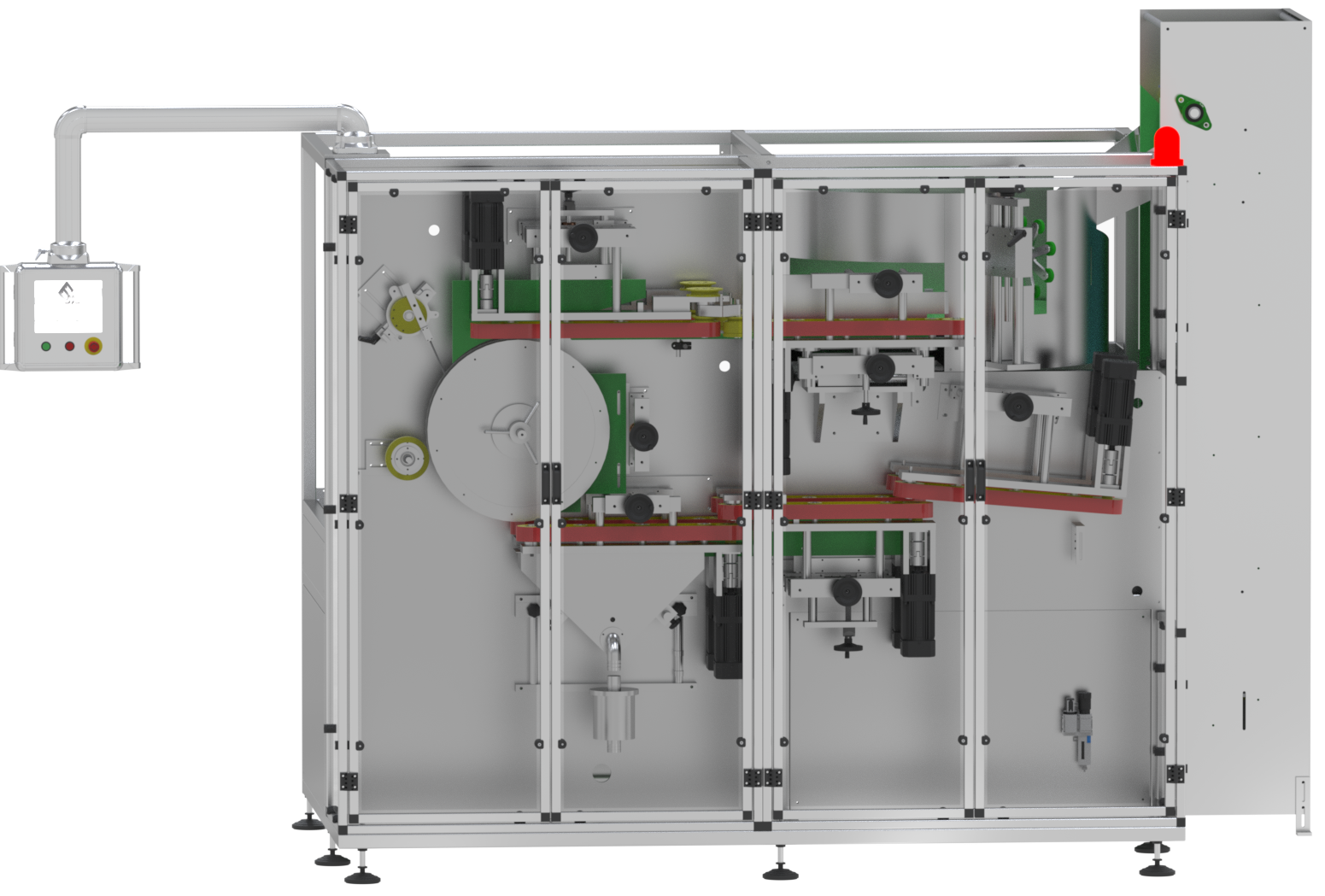

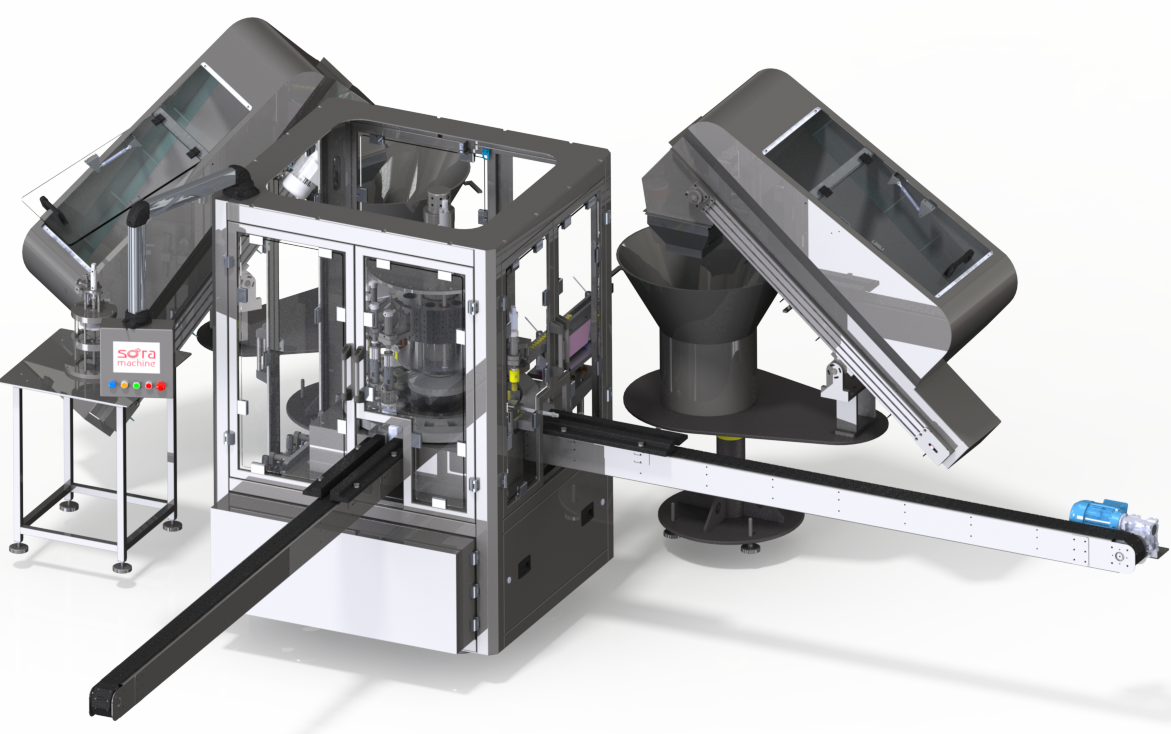

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

- Product contact parts: AISI 316 or AISI 304 (quoted based on AISI 304)

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Scrolls, change parts and plastic covers on guide rails are anti-static

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

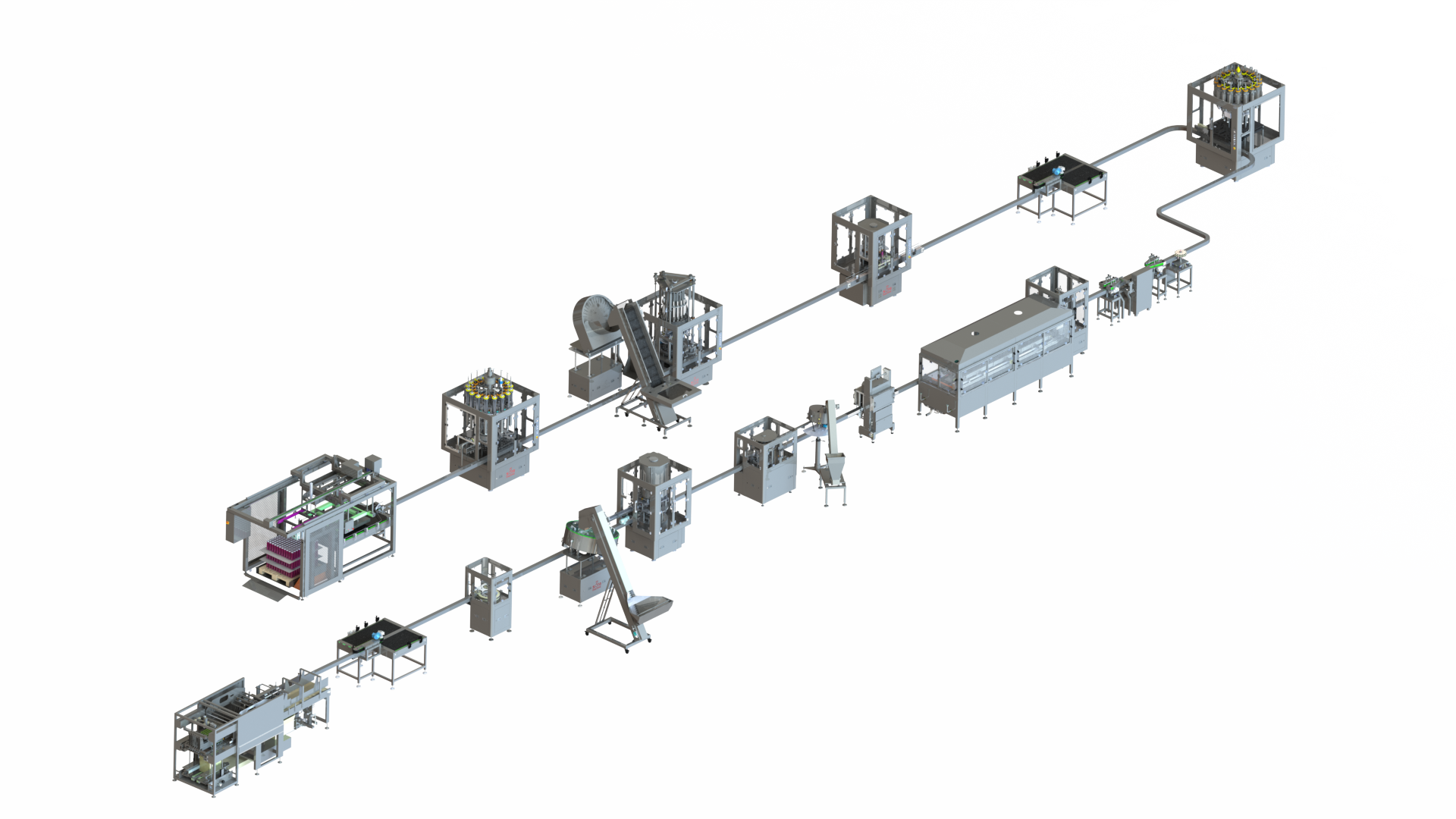

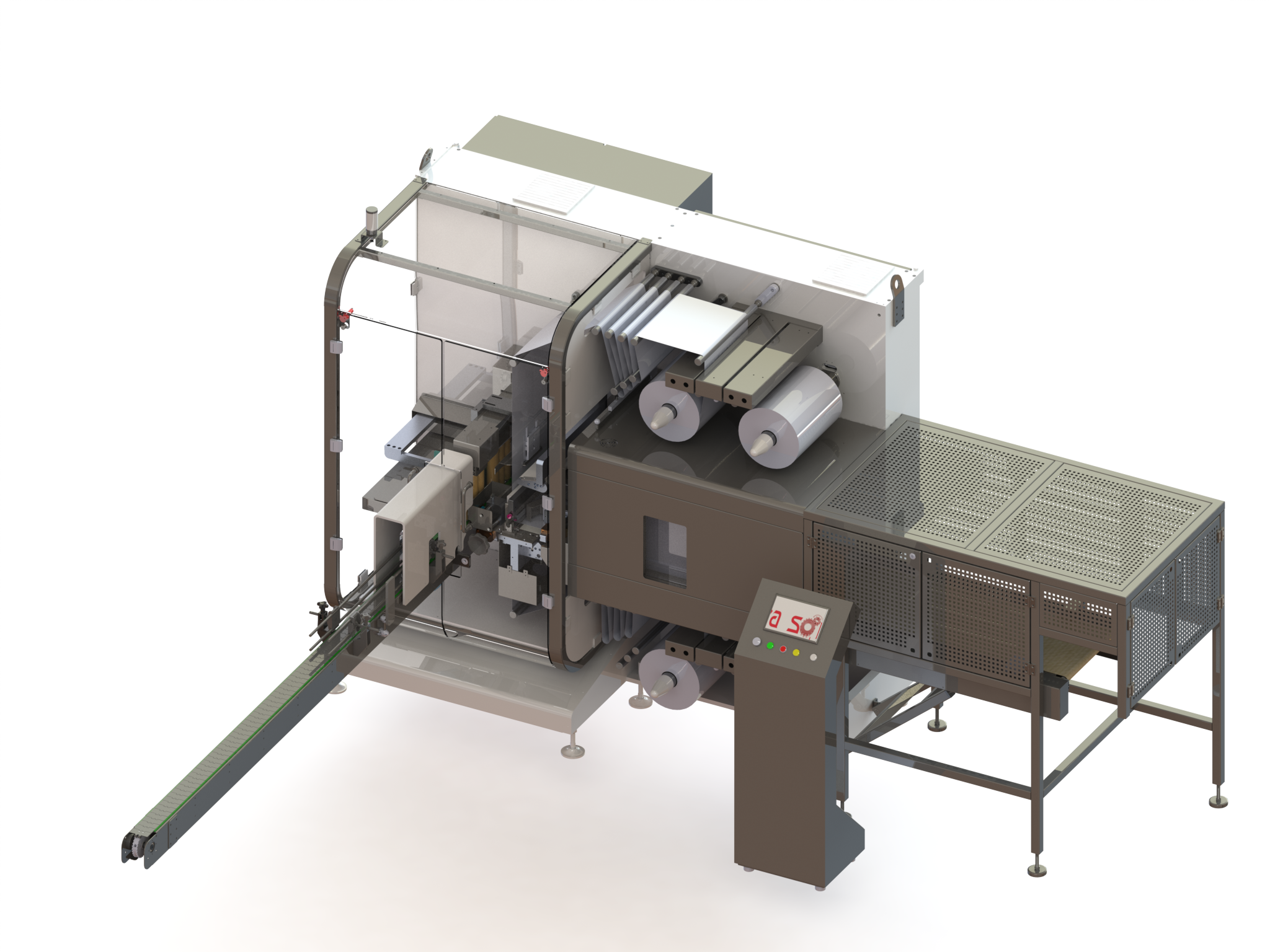

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

- Product contact parts: AISI 316 or AISI 304 (quoted based on AISI 304)

- All the motors, sensors, control panels on machines, plc, whole buttons (in zone 1 and zone 2) used on line are ex-proof (ATEX)

- Dosing accuracy: +/- 1%

- Machine construction: AISI 304

- Product contact parts: AISI 316 or AISI 304 (quoted based on AISI 304)

Test İçerik Test İçerik Test İçerik Test İçerik

Test İçerik Test İçerik Test İçerik Test İçerik Test İçerik Test İçerik Test İçerik Test İçerik Test İçerik

Our References

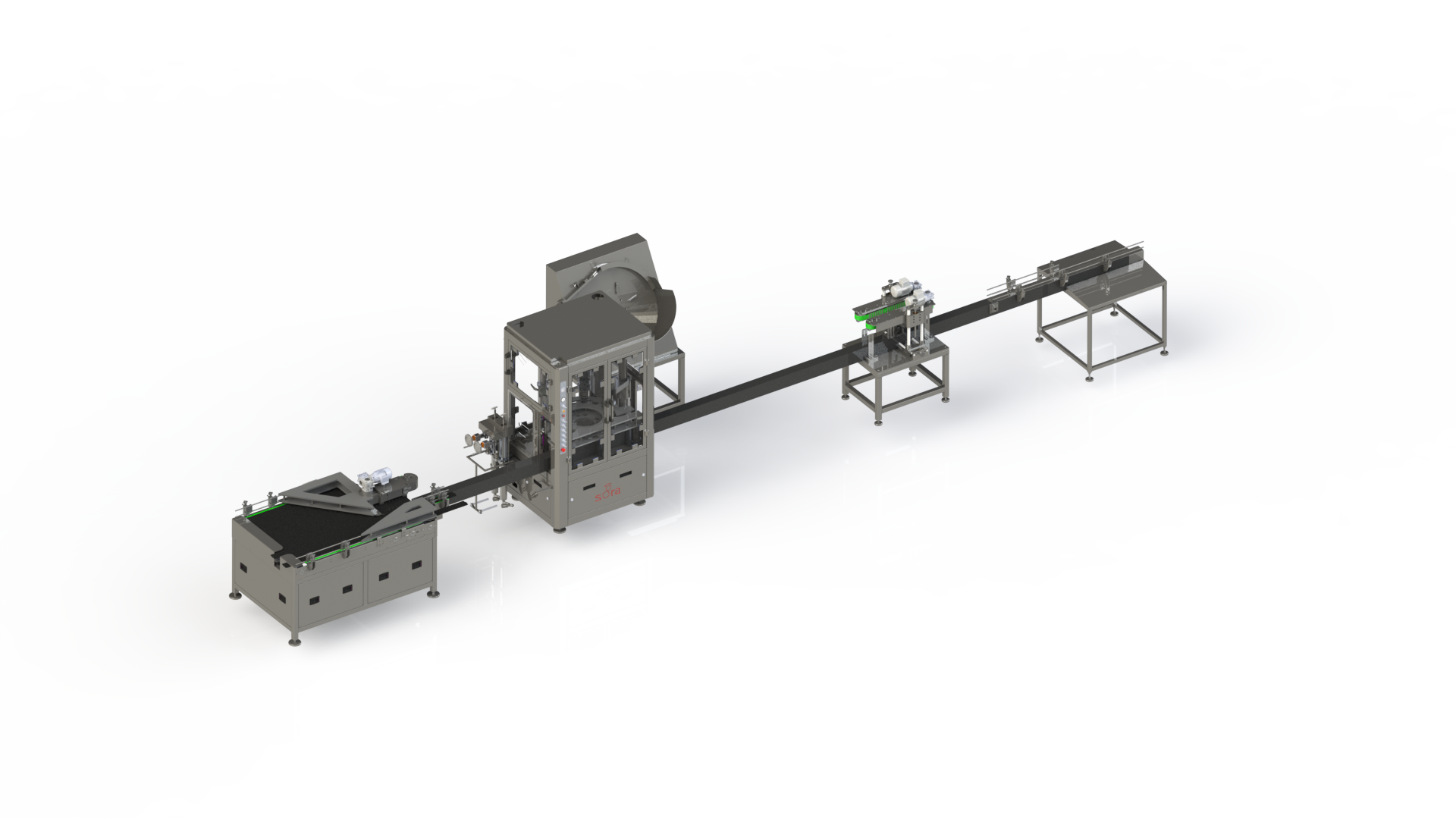

As Sora Makine, we provide Technology Support and Production Solutions to the World’s Leading Brands.