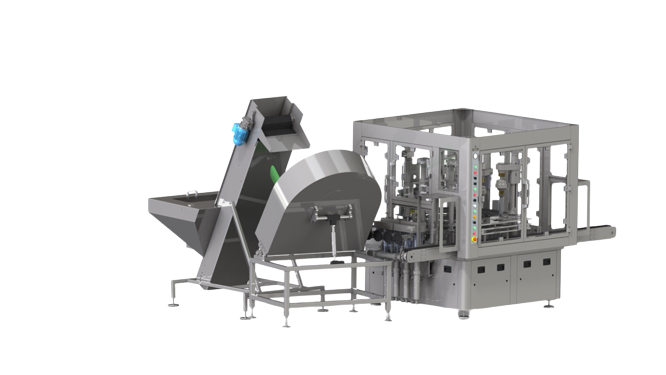

Index Type Crimping & Compressed Air Filling Unit & Pressure Control

The Index Type Crimping & Compressed Air Filling Unit & Pressure Control is an advanced, integrated machine engineered for the precise sealing and simultaneous pre-pressurization of aerosol cans. This unit features a Standard 1” valve crimping head and employs pneumatic control to allow for the individualized determination and adjustment of pressure. Crucially, the machine fills the can with a required amount of air concurrently during the crimping process. Built from AISI 304 Stainless Steel, this equipment ensures high durability and sanitation standards, delivering consistent, high-quality aerosol products through precisely set crimp height and depth. The machine is recognized for its qualitative features, including quick setting crimp-diameter, crimp-depth, and auto-adjustment capabilities.

Technical Advantages

This indexing unit provides highly technical advantages focused on control and reliability:

- Standardized Crimping Head: Equipped with a standard 1” valve crimping head to accommodate common industry specifications.

- Precision Sealing Control: The height and depth of the crimp are precisely set, a feature designed to significantly enhance production safety and guarantee a high quality aerosol product.

- Simultaneous Air Injection: The unit fills the can with a precise amount of compressed air concurrently during the crimping cycle.

- Adjustable Air Specifications: The system features adjustable air pressure and specific air pressure control mechanisms.

- Rapid Adjustment Features: The machine is known for qualitative features such as quick setting crimp-diameter, crimp-depth, and integrated auto-adjustment functionalities.

- Robust Material Construction: The main equipment and construction utilize AISI 304 Stainless Steel.

- Required Input Pressure: The unit provides 8 bars of pressure for the can, which requires the assistance of an external compressor supplying at least 10 bar.

Technologies Used

The machine utilizes established industrial technologies for control and reliable operation:

- Advanced Pneumatic Control System: The core functionality relies on a pneumatic control system, allowing for the individual determination of pressure parameters.

- Integrated Air Pressure Control: Dedicated technology is included for precise management and control of the internal air pressure applied during the sealing phase.

- AISI 304 Engineering: The selection of AISI 304 Stainless Steel for all construction and equipment ensures resistance to corrosion and adherence to sanitation requirements common in processing environments.

- Safety Interlock System (No Can No Fill): A sophisticated “No Can No Fill System” is implemented to prevent operational cycles and air consumption if a container is not detected in the proper position.

- Mechanized Height Adjustment: Features an easy and adjustable can height setting mechanism, facilitating quick setup and changeovers for varying can sizes.

Industrial Usage Areas

This specialized unit is essential for industries where precise container sealing and controlled internal pressurization are mandatory:

- Aerosol Manufacturing: This is the primary application, utilized in the production of various aerosol products where consistent valve crimping and initial air filling are required (e.g., technical sprays, specialized industrial products).

- Specialized Packaging Operations: Applicable to any industrial process requiring Standard 1” valve crimping alongside simultaneous internal pressure application.

- Industrial Filling Solutions: The machine forms a core component within industrial filling machine solutions.

Operational Benefits

The implementation of this Index Type Crimping and Filling Unit provides several key operational and quality benefits for factory management and production teams:

- Guaranteed Product Quality and Safety: By allowing the precise setting of crimp height and depth, the machine significantly increases production safety and ensures the high quality of the aerosol product by achieving an optimal, reliable seal.

- Minimized Waste and Enhanced Efficiency: The “No Can No Fill System” prevents the waste of compressed air and minimizes operational clean-up by ensuring the air filling cycle only executes when a can is present.

- Rapid Changeover Capability: Features like the quick setting crimp-diameter, crimp-depth, and easy and adjustable can height setting streamline changeover processes between different product specifications, maximizing uptime.

- Durability and Compliance: The use of AISI 304 Stainless Steel ensures a durable, long-lasting machine structure that meets industrial hygiene standards.

Differentiation from Competitors

This machine is set apart by its emphasis on integrated control and quality assurance features:

- Integrated Simultaneous Functionality: A key differentiation is the capacity to fill the can with compressed air during the crimping action. This integration streamlines the process and ensures an immediate seal following pressurization.

- Advanced Qualitative Controls: The machines are specifically known for their qualitative features including the rapid adjustment mechanisms and auto-adjustment capabilities for crimp parameters.

- Granular Pneumatic Management: Offering pneumatic control that allows for the individual determination of pressure provides a higher degree of precision and process customization compared to standard systems.