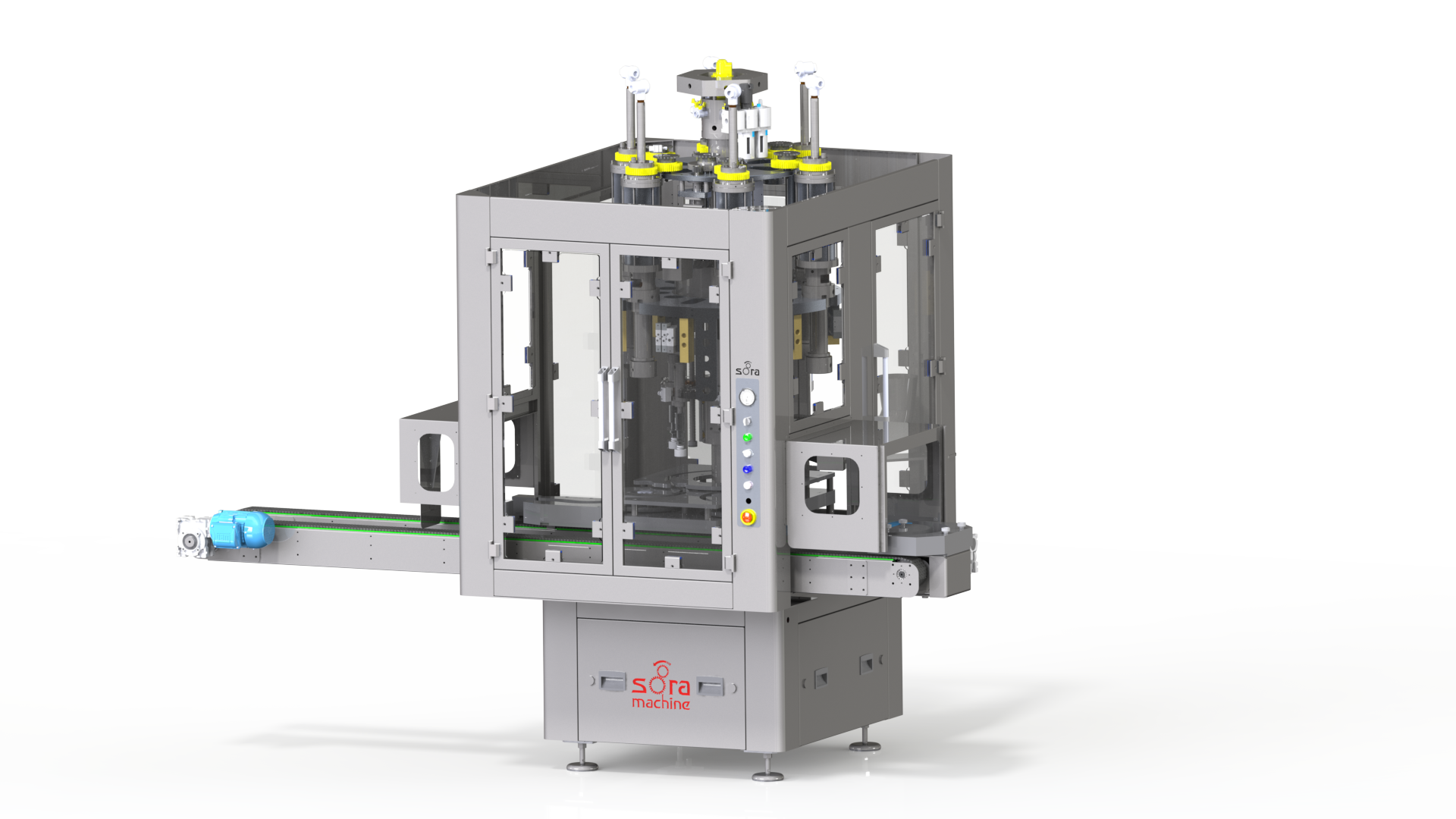

ROTARY TYPE 6 HEADS PROPELLANT FILLING MACHINE

The Rotary Type 6 Heads Propellant Filling Machine is a high-performance, industrial-grade gas injection system engineered for continuous high-speed aerosol production lines. Constructed from premium AISI 304 quality stainless steel, this unit is designed to handle both tinplate and aluminum cans with exceptional durability. By utilizing a Rotary Continuous Motional working system, the machine ensures a seamless flow of containers, significantly increasing throughput compared to traditional indexing systems.

Technical Advantages

- Precision Gas Injection: Features 6 specialized gas injecting heads providing a remarkable filling accuracy of ±1%, ensuring consistent product quality and minimizing propellant waste.

- Continuous High-Speed Operation: The rotary motion system eliminates the stops and starts of conventional fillers, maximizing line efficiency.

- Certified Safety for Hazardous Zones: Specifically engineered for Explosion Proof Zone 1 areas, featuring an Ex-Proof conveyor motor and an ATEX button box for operator control.

- Robust Material Integrity: The entire construction utilizes AISI 304 quality stainless steel, offering superior resistance to corrosion and wear in industrial environments.

- Versatile Container Compatibility: Designed to seamlessly process both tinplate and aluminum can types without compromising stability.

Used Technologies

- Pneumatic Control Architecture: The machine operates on a completely pneumatic control system, which is essential for safety and reliability in gas-heavy environments.

- Specialized Driving Mechanism: Employs a special pneumatically operated clutch for the machine driving system, providing smooth torque transmission and engagement.

- Advanced Safety Interfaces: Integration of an ATEX-rated button box allows for safe manual intervention within high-risk explosive zones.

- Ex-Proof Motor Technology: The conveyor system is driven by a certified Ex-Proof motor, mitigating the risk of ignition in the presence of flammable propellants.

Industrial Usage Areas

This machine is a critical component for high-volume manufacturing facilities in several sectors:

- Aerosol Production: Ideal for the primary injection of propellants into pressurized containers.

- Cosmetics and Personal Care: Suitable for deodorants, hairsprays, and shaving foams where AISI 304 hygiene standards are required.

- Technical Chemicals: Used for filling industrial lubricants, cleaners, and spray paints into tinplate or aluminum cans.

- Pharmaceutical Packaging: Applicable for aerosolized medical products requiring high filling accuracy.

Operational Benefits

- Energy Efficiency: Despite its high-speed performance, the machine maintains a low energy consumption profile of only 1.5kw.

- Increased Safety and Compliance: The Zone 1 explosion-proof rating ensures your facility meets the highest safety standards for flammable gas handling.

- Reduced Maintenance Downtime: The completely pneumatic control system and special pneumatic clutch simplify troubleshooting and maintenance compared to complex electronic alternatives.

- High ROI through Accuracy: The ±1% filling accuracy ensures precise propellant usage, leading to significant cost savings in raw materials over large production runs.

Technical Specification

| Specification | Value |

| Heads | 6 Gas Injecting Heads |

| Working System | Rotary Continuous Motional |

| Filling Accuracy | ±1% |

| Explosion Proof Rating | Zone 1 (ATEX) |

| Construction Material | AISI 304 Quality Stainless Steel |

| Control System | Completely Pneumatic |

| Energy Consumption | 1.5 kW |

| Air Requirements | 6 – 10 Bar |

| Driving System | Special Pneumatically Operated Clutch |

| Can Types | Tinplate, Aluminum |

| Conveyor Motor | Ex-Proof |

| Operator Interface | ATEX Button Box |