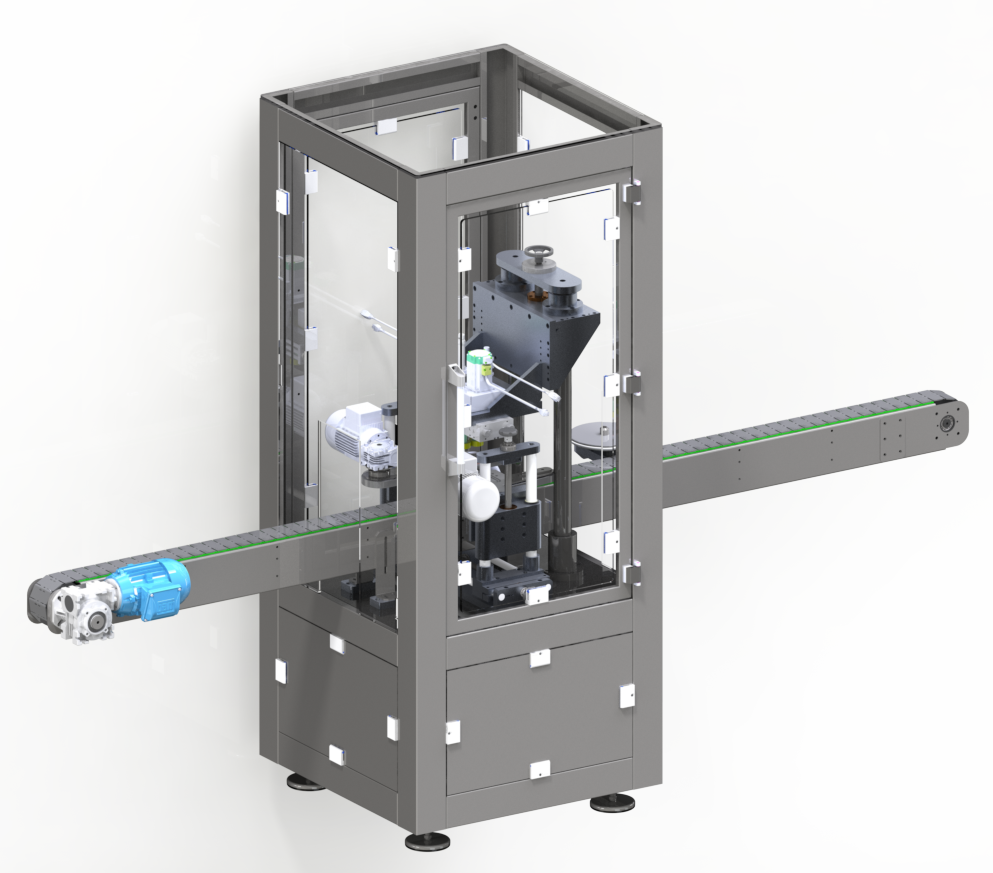

PUMP TIGHTENING SYSTEM

The PUMP TIGHTENING unit is a high-performance, semi-automated machine dedicated to securing various bottle closures, including screw caps and push-pull pumps. This system is distinguished by its torque control with servo motor for screwing, ensuring exceptional accuracy and consistent application force. Operationally, the machine utilizes a pneumatic system requiring 6-8 bar air, powered by an Ober air motor (NON-ATEX) 3 collective system. Although cap insertion is performed linearly and manually, the machine’s capacity is designed to be integrated with an existing filling station. Comprehensive safety is addressed through a machine guard and safety switches, alongside an ATEX HMI control and button box.

Technical Advantages

- Precision Torque Application: Features torque control with a servo motor, providing highly accurate and repeatable screwing force crucial for achieving leak-proof sealing across high-volume production runs.

- Safety Control Interface: Equipped with an ATEX HMI control and button box, ensuring the primary control interface meets standards for environments where explosion risk management is required.

- Robust Container Handling: Incorporates a bottle holder system with a band speed controller, allowing for synchronized movement and stability of containers during the tightening process.

- Sealing Stabilization: Uses a presser unit with a piston to stabilize the closure and container during the critical screwing phase, guaranteeing consistent vertical alignment.

- Specific Motor Configuration: Driven by an Ober air motor (NON-ATEX) 3 collective system, which operates efficiently on a standard 6-8 bar required air supply.

- Integrated Safety Measures: Includes a comprehensive machine guard and safety switches to protect operators and ensure compliance with mandatory industrial safety standards.

Utilized Technologies

The PUMP TIGHTENING system relies on a combination of advanced control, motorization, and interface technologies:

- Advanced Servo Drive Technology: The primary function, screwing, is managed by a servo motor, which provides closed-loop feedback for precise torque control. This technology is essential for fine-tuning the closure force based on product specifications.

- Pneumatic Power System: The system is fundamentally pneumatic, requiring 6-8 bar and utilizing an Ober air motor for operational movement, offering robust performance in industrial settings.

- Explosion Protection Interface: The inclusion of an ATEX HMI control and button box indicates the implementation of technology compliant with ATEX directives concerning hazardous environments, specifically for the Human-Machine Interface.

- Synchronized Motion Control: The band speed controller integrated into the bottle holder system utilizes motion control technology to synchronize the container movement with the tightening cycle.

Industrial Applications

The PUMP TIGHTENING machine is an essential component for streamlined liquid packaging operations, particularly where precise application of specific closures is necessary.

- Liquid Filling Lines: Its capacity is integrated with filling station, making it ideal for immediate post-fill closure operations.

- Cosmetics and Personal Care: Suitable for products requiring secure screw caps or specialized push-pull dispensing mechanisms, commonly found in lotions, cleaners, and liquid soaps.

- Aerosol Manufacturing Support: As Sora Machine provides solutions across Aerosol, Cosmetics, Liquid Filling, and Pharmaceutical sectors, this unit fits seamlessly into packaging lines requiring the sealing of components like pump triggers or screw caps.

- General Bottling: Any facility handling high volumes of product that require accurate, controlled tightening of caps and pumps.

Operational Benefits

- Guaranteed Product Quality: The servo motor-driven torque control minimizes the risk of over- or under-tightening, virtually eliminating product leaks and ensuring consistent consumer experience and brand integrity.

- Seamless Line Flow: The machine’s capacity is integrated with the filling station, optimizing production flow and minimizing buffer requirements between filling and closure stages.

- Increased Operator Safety: Comprehensive safety features, including the machine guard and safety switches, combined with the ATEX HMI control, significantly reduce operational risk and downtime associated with incidents.

- Handling Versatility: The capability to handle both screw caps and push-pull closures provides flexibility for manufacturers managing diverse product portfolios on a single line.

- Consistent Container Presentation: The bottle holder system with band speed controller and the piston-based presser unit ensure containers are held firmly and presented consistently, maximizing tightening success rates.