Sora Machine: Turkey’s Leading Aerosol Machine Manufacturer

Sora Machine was founded in 1981 by Mr. Yılmaz Kesme who is the father of Barış Kesme, CEO of Sora Group. Sora is the first manufacturer of aerosol product machines in Turkey and currently offers solutions to its customers with the most recent technology and innovative business highlights.

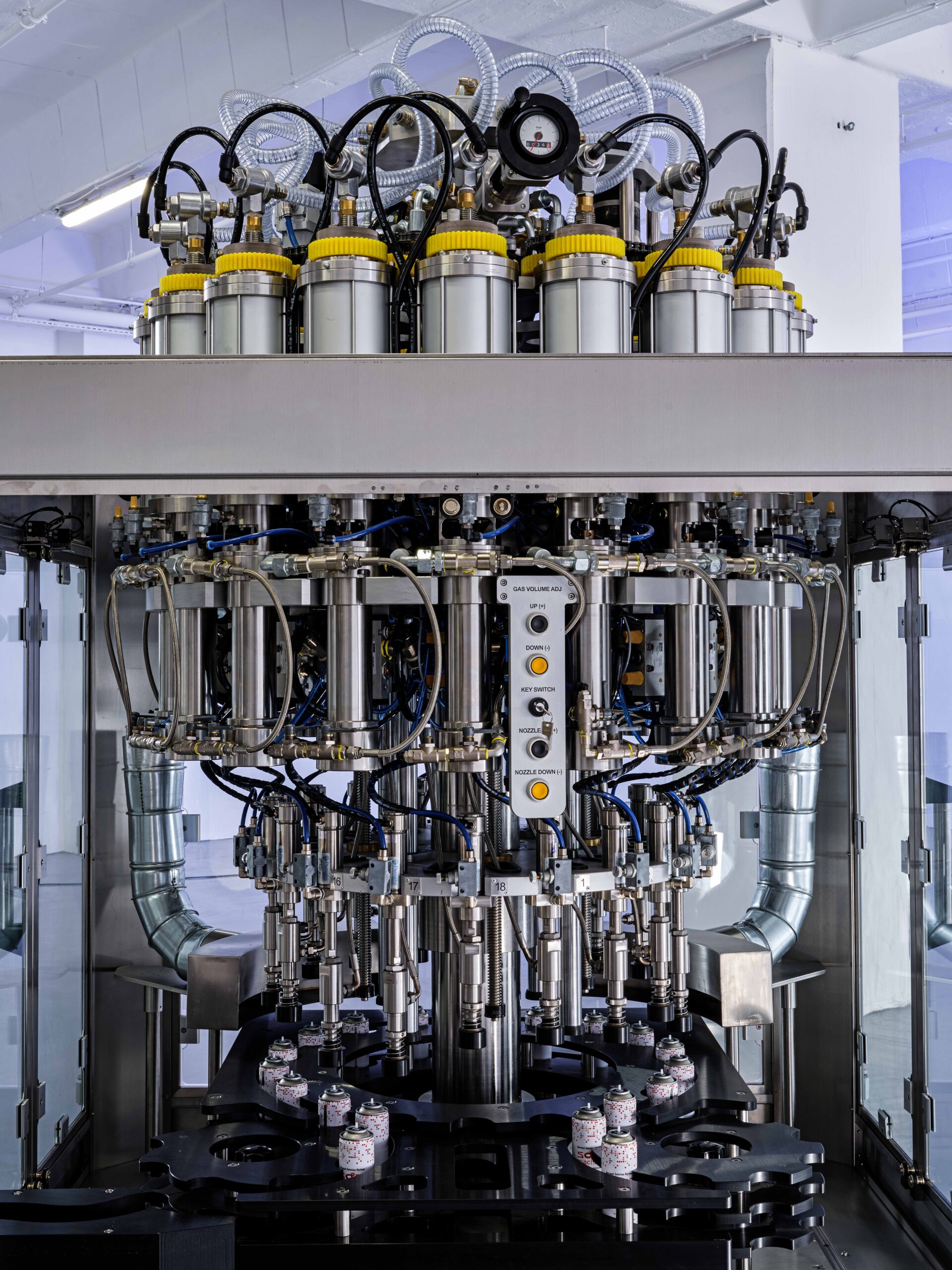

Sora Machine pioneers the aerosol machine manufacturing industry. With over 40 years of experience, it provides high-tech aerosol machine solutions for the cosmetic, pharmaceutical, and packaging industries. By offering turnkey projects, it designs aerosol production systems and aerosol filling machines that best suit its customers’ needs.

Aerosol production technologies are focused on efficiency and sustainability. Sora Machine offers innovative, customizable, and economical solutions for aerosol filling and packaging machines. With its technological infrastructure and R&D activities, it quickly produces solutions for all kinds of needs in the sector.

Always solution-oriented and customer-focused, Sora Machine brings a new vision to the aerosol industry. Sora Machine’s aerosol production, filling machines, and packaging systems are the ideal choice for businesses seeking reliable and high-quality solutions in the global market.

Mission

To exceed service level expectations of our customers with our mutual respect and honesty principle towards society and our environment.

Vision

Being one of the sector’s leading companies in the world with innovative, quality and customer oriented service understanding.Sora Machine aims to protect its respectable brand by offering high service standards its customers.

Sora Machine is your solution partner and

your products are in good hands.

Our References

As Sora Machine, we provide Technology Support and Production Solutions to the World’s Leading Brands.

Photo and Videos From

Sora Machine

Sora Machine - FAQ

Sora Machine, as a brand specializing in aerosol filling technologies, offers highly efficient production systems to the cosmetics, pharmaceuticals, cleaning, automotive, packaging, and chemical sectors. Thanks to its wide sector portfolio, it has the capability to produce solutions tailored to the specific needs of each customer. It plays an active role especially in the production of various products ranging from spray deodorants.

A turnkey solution is a comprehensive project system where the entire process of a production facility, including planning, machine manufacturing, installation, commissioning, testing, and after-sales services, is managed by Sora Machine from a single point.

The advantages of this model include:

- Saves time.

- Facilitates cost control.

- Offers maximum efficiency with compatible systems.

- Ensures seamless communication with a single point of contact.

Thanks to Sora Machine’s engineering infrastructure, your production line starts operating reliably from day one.

These machines are used in the production of products such as deodorants, hair sprays, cleaning sprays, paints, pharmaceutical sprays, and similar items. Different filling technologies can be applied for any product containing liquid, foam, or pressurized gas.

- Automatic systems are ideal for high production volumes. Human intervention is minimal, and production is continuous with standard quality.

- Semi-automatic machines offer flexibility for lower volume productions or those requiring variety.

Determining which system is suitable for you requires evaluating your production capacity, product type, and budget together.

Sora Machine’s machines are equipped with many advanced safety features such as leak detection systems, emergency stop buttons etc.

These systems, which can operate safely in potentially explosive environments, comply with international safety standards such as ATEX.

With proper use and regular maintenance, these machines can operate without issues for over 10 years. Sora Machine’s developed modular system design facilitates part replacements and technical interventions, extending the lifespan of the equipment.

- Machine health is monitored through periodic checks.

- Preventive maintenance can be performed thanks to pre-failure warning systems.

- Operator training minimizes human errors.

Furthermore, Sora Machine offers immediate intervention possibilities in case of failures through remote access support systems.

Trained personnel use filling lines correctly and efficiently, both speeding up production and preventing breakdowns. Sora Machine provides specific user training for the machines it delivers.

Every product undergoes quality control with automatic testing systems integrated into the filling machines, such as:

- Filling level sensors,

- Pressure testing devices,

- Leak detection devices.

Moreover, these systems report quality data, ensuring traceability.

Sora Machine’s production processes are in full compliance with standards such as:

- FEA (European Aerosol Federation),

- ATEX,

- ISO 9001.

If you wish, you can fill out the contact form on our website and start project work with our expert teams.