Aerosols are commonly used in various industries, from personal care products to cleaning supplies and even in the food industry. However, transporting and storing these products involves careful adherence to specific safety standards and regulations. Proper aerosol packaging ensures that products are delivered safely, without risk to people, property, or the environment. In this article, we will discuss the essential rules for packaging aerosols during transportation and storage, focusing on their classification as dangerous goods, the need for proper packaging materials, and the measures needed to protect the integrity of aerosol cans.

How Should Aerosols Be Packaged Before Transportation?

When it comes to transporting aerosol cans, safety is a priority. The packaging of aerosols before transportation must be done with extra care to prevent accidents such as leaks, explosions, or damage during transit. Aerosols are pressurized containers, and if mishandled, they can pose significant risks.

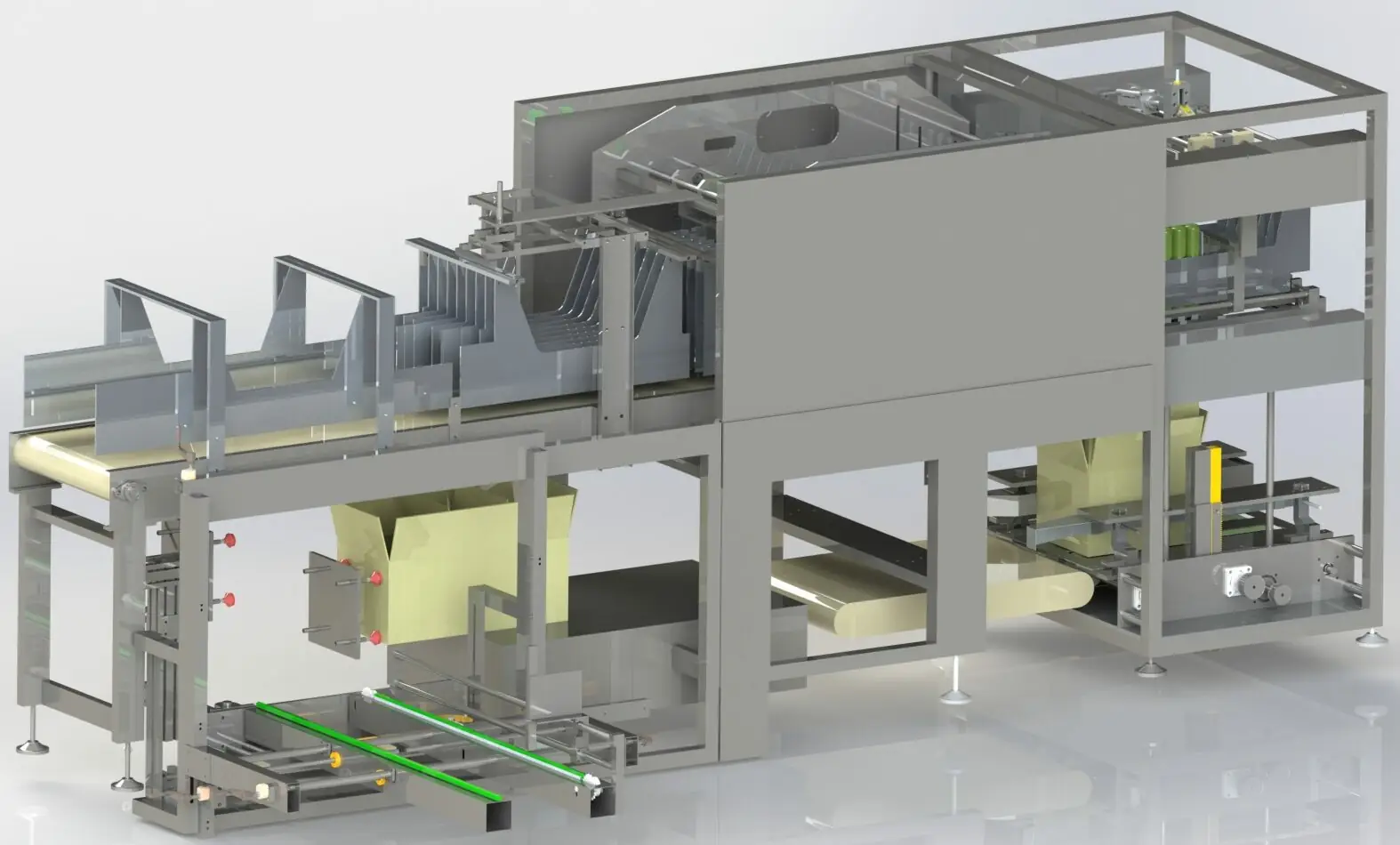

Packaging for aerosol transportation should always be designed to handle the specific risks associated with these products. It’s crucial to use sturdy, impact-resistant boxes that are capable of absorbing shock in case the cans are dropped. The boxes should also be lined with materials that prevent the cans from shifting inside, which could cause pressure buildup or damage. Additionally, since aerosols often contain flammable or hazardous materials, the outer packaging must be clearly labeled with appropriate warning signs.

Aerosol transportation rules also require the use of specific containers that comply with UN regulations. These containers are designed to meet the requirements of hazardous materials handling and are intended to minimize the risk of accidents or leaks during transport.

What Should Be Considered Regarding The Packaging Of Aerosols Before Storage?

Aerosol storage standards are just as important as transportation rules, ensuring that the product remains safe in a warehouse or storage facility. One of the key factors to consider when packaging aerosols for storage is temperature control. Aerosol cans are sensitive to extreme temperatures, and storing them in an area where temperatures can fluctuate drastically can lead to dangerous situations.

For safe storage, aerosol cans should be kept in a well-ventilated area that is not exposed to direct sunlight or excessive heat. It is essential to store these products away from sources of heat or open flames, as they contain pressurized gases that could cause the cans to explode if exposed to extreme temperatures. Furthermore, since many aerosol products contain flammable goods, it is critical to ensure that the storage space is compliant with fire safety regulations.

Another important consideration is the ability to quickly inspect the cans. Storage areas should allow for easy access to check the condition of the aerosol cans, ensuring that no cans are leaking, bulging, or showing signs of damage.

Do Aerosol Products Fall Under The Category Of Dangerous Goods?

Yes, aerosol products generally fall under the category of dangerous goods. Many aerosols contain flammable liquids, gases, or propellants, which make them hazardous to transport and store. According to the Dangerous Goods Regulations (DGR), these products require special handling, labeling, and packaging.

Aerosols containing flammable materials, like propane, butane, or alcohol, are classified as dangerous goods due to their potential to catch fire or explode under certain conditions. It is essential that anyone involved in the transportation or storage of these products is aware of the specific dangerous goods packaging regulations that apply.

For example, under the ADR (Accord européen relatif au transport international des marchandises Dangereuses par Route) regulations, which govern the transport of dangerous goods in Europe, aerosol products are subject to strict rules regarding labeling, storage, and transportation methods. These rules ensure that dangerous goods like aerosol cans are safely managed, reducing the risk of accidents.

Which Standards Must The Packaging Materials Used in Transportation Comply With?

The packaging materials used in aerosol transportation must meet several standards, most notably the UN packaging codes. These codes are part of international regulations that ensure packaging materials are strong enough to withstand the rigors of transport while also protecting the integrity of the contents.

The UN codes ensure that packaging has been tested and certified for specific safety requirements, such as resistance to puncturing, leakage prevention, and ability to withstand the pressures associated with transportation. These codes are crucial for identifying packaging that meets international safety and quality standards. If the packaging does not comply with these regulations, the risks of accidents or product failure during transportation increase significantly.

Why are UN Codes And Symbols Important in The Transportation Of Aerosols?

UN codes and symbols play a vital role in the safe transportation of aerosol products. They are universally recognized identifiers that indicate the type of product being transported and whether it is classified as a dangerous good. These codes are an essential part of the documentation required when shipping aerosols and serve as a clear warning to handlers, transporters, and emergency responders.

The UN symbols also help to ensure that the appropriate precautions are taken throughout the transportation process. For example, a label with a UN number indicates that the aerosol is pressurized or contains hazardous substances, so handlers are aware of the risks and can take the necessary steps to ensure safety.

Without proper use of UN codes and symbols, the transportation of aerosols could become unsafe, with potential for accidents during handling, transport, and unloading. These codes also facilitate international shipping, ensuring that aerosol products are treated with the appropriate level of caution across borders.

Why is The Vertical Transportation Of Aerosol Cans Mandatory?

The vertical transportation of aerosol cans is mandatory because of the specific risks associated with these products. Aerosol cans are pressurized, and transporting them horizontally can increase the risk of rupture or leaks. When placed vertically, the pressure inside the can is distributed more evenly, reducing the chances of damage or failure.

Additionally, storing or transporting aerosol cans upright helps to prevent leakage of the propellant, which can be volatile. Keeping them in a vertical position also ensures that the valve on the can remains intact, preventing unintended release of the contents during transport.

What Measures Should Be Taken To Protect Against High Temperature And Impact?

High temperatures and impact are two of the most significant threats to aerosol products during transportation and storage. To protect against high temperatures, it is essential to use insulated and well-ventilated packaging. Insulation helps to minimize the effects of external heat sources, while proper ventilation allows any pressure buildup inside the can to be released safely.

Impact protection is another crucial element of aerosol packaging. The outer packaging should include padding or cushioning materials to absorb shocks and prevent the aerosol cans from being damaged during transport. By using strong, durable packaging materials, the risk of cans being punctured or damaged is minimized, ensuring the safe transport of the aerosols.

How Should Ventilation And Temperature Control Be Ensured in The Storage Area?

In storage areas, proper ventilation and temperature control are essential for maintaining the safety and integrity of aerosol products. Ventilation allows any potentially harmful fumes to dissipate, reducing the risk of exposure to hazardous chemicals. Temperature control ensures that aerosol cans are stored within the recommended temperature range, preventing the risk of the cans overheating or exploding due to excessive heat.

What Additional Precautions Are Needed For Aerosol Products Containing Flammable Gas?

Aerosol products containing flammable gas require additional precautions due to the heightened risk of fire or explosion. These products must be clearly labeled with flammable symbols, and storage areas should be equipped with fire suppression systems. Moreover, aerosol cans containing flammable gas should be kept away from open flames, sparks, and other sources of ignition.

How Can The Risks Of Leakage Or Explosion During Transport Be Reduced?

The risks of leakage or explosion during the transportation of aerosols can be significantly reduced by following strict packaging rules and safety protocols. The packaging must be impact-resistant, sealed tightly to prevent leakage, and designed to handle changes in temperature and pressure.

To further reduce the risks, it’s important to train personnel handling aerosol products, ensuring they understand the necessary precautions and how to respond in case of an emergency. Emergency response plans should also be in place, with clear procedures for dealing with potential leaks, spills, or explosions.

By following the right guidelines for aerosol packaging, transportation, and storage, businesses can ensure that these products reach their destination safely and without incident.