When it comes to packaging liquids, the importance of an efficient capping system cannot be overstated. Liquid capping machines are essential in ensuring that bottles, jars, and other containers are sealed properly, ensuring product quality and shelf life. But with the variety of cap types on the market, selecting the right capping machine can be a challenge. In this article, we’ll explore how liquid capping machines work, the different types of caps they can handle, and how these machines are integral to the efficiency of liquid filling lines.

What Are the Types of Caps Used in Liquid Filling?

In the world of liquid packaging, caps come in a variety of forms, and each type serves a unique purpose. Some of the most commonly used caps in liquid filling include:

- Screw Caps: These are among the most popular and versatile cap types, used for everything from beverage bottles to household cleaners.

- Snap-On Caps: These caps are often used in consumer products like cosmetics and pharmaceuticals, where a secure, yet easy-to-open seal is required.

- Pump Caps: These are typically used for products like lotions, creams, or soaps, where a controlled dispensing mechanism is needed.

- Child-Resistant Caps: Used for safety reasons in products like medicine, these caps require a special mechanism to open.

- Flip-Top Caps: Commonly found in sauces and shampoos, these caps are hinged and easy to flip open.

Each cap type requires specific handling during the capping process, which is where capping machines come in. The right capping machine can help prevent wastage, contamination, and maintain product integrity.

Which Cap Types Can Capping Machines Be Compatible With?

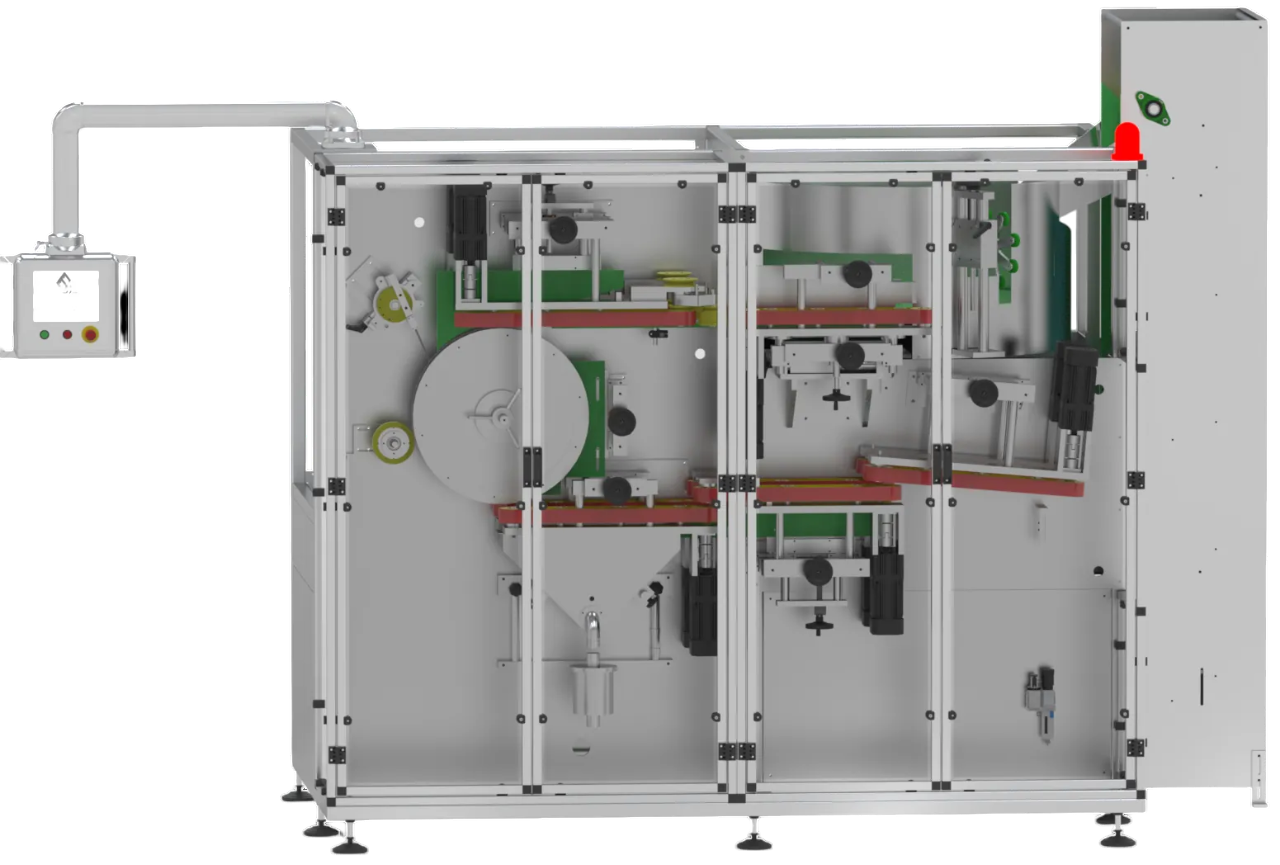

Modern liquid capping machines are designed to handle a wide variety of caps. They offer great flexibility and can be adjusted to handle everything from basic screw caps to more specialized options like snap-on or flip-top caps. For example, automatic screw capping machines are equipped to handle the torque and precise sealing required for screw-on lids, while snap-on capping machines are ideal for ensuring that lids snap into place securely.

A key feature of advanced capping systems is their versatility. Some machines are designed with multi-head configurations, allowing them to handle different cap types on the same production line. This adaptability is critical for businesses that need to switch between products quickly or offer multiple packaging options.

What Are the Differences Between Automatic Capping Machines and Manual Systems?

While manual capping systems can be suitable for small-scale or low-volume production, automatic capping machines offer significant advantages in terms of speed, precision, and scalability. Automatic machines can cap hundreds or even thousands of bottles per hour, all while maintaining high consistency and quality. They also reduce the need for manual labor, which lowers the risk of human error and enhances workplace safety.

Manual capping systems, on the other hand, are slower and typically require more hands-on attention. They can be useful for limited runs or for products that are produced in small quantities. However, for high-efficiency production lines, automatic capping machines are the preferred choice.

How Do Multi-Head Capping Machines Work?

Multi-head capping machines are designed to speed up the capping process. These machines feature multiple capping heads that work simultaneously, sealing multiple containers at once. This setup significantly increases throughput, reducing bottlenecks in the production line.

For example, in an industrial liquid filling line, a multi-head capping machine might have anywhere from two to six heads, depending on the production capacity needed. Each head is equipped with the necessary mechanism to apply a cap to each container, and adjustments are made to ensure that the torque and pressure applied are consistent across all caps.

How Are Torque Adjustments Made According to the Cap Type?

One of the key features of liquid capping machines is their ability to adjust torque. Torque refers to the amount of force used to tighten the cap onto the container. Different cap types require different amounts of torque to ensure they are sealed correctly without being over-tightened, which could damage the cap or the container.

For instance, screw caps require a certain amount of torque to ensure that they are tightly sealed, while snap-on caps need much less torque as they simply need to snap into place. Modern capping machines feature torque adjustment systems that can be fine-tuned based on the type of cap being used, ensuring a secure seal without risk of damaging the product.

Are Special Designs Needed for Snap-On, Screw Caps, and Pump Caps?

Yes, each of these cap types requires special design considerations in the capping machine. For snap-on caps, the machine needs to be able to apply the right amount of pressure to ensure the cap securely attaches to the container. This is often done using a system that aligns the cap perfectly before snapping it onto the bottle.

Screw caps require a torque-controlled system to ensure they are not too tight or too loose. Over-tightening can lead to difficulty in opening the container, while under-tightening can cause leakage. For pump caps, the machine must ensure that the cap is correctly aligned and that the pump mechanism is securely attached to avoid any malfunction or leakage.

How Is a Capping Machine Configured According to Different Packaging Sizes?

When dealing with a variety of packaging sizes, flexibility is key. Capping machines can be configured to accommodate different bottle sizes, shapes, and cap types. This is typically achieved through adjustable platforms and interchangeable parts that can be swapped out depending on the packaging specifications.

For example, the capping machine might have a set of adaptable nozzles or conveyors that can be adjusted to handle different heights and diameters of containers. This flexibility allows manufacturers to use the same capping machine for different product lines, reducing the need for multiple machines and streamlining the production process.

Which Technologies Do Cap Alignment Systems Use?

Cap alignment systems are crucial in ensuring that each cap is applied correctly to its container. These systems often use a combination of mechanical and optical technologies to align the cap with the neck of the bottle before sealing it. Some systems use sensors to detect misaligned caps and make real-time adjustments, ensuring that the caps are always correctly positioned.

Other systems may incorporate advanced robotics or pneumatic systems to gently guide the caps into place. The goal is to reduce the chances of misapplication, which could result in product waste or contamination.

How Are Capping Systems Optimized During Fast Product Changeovers?

One of the main challenges in liquid filling lines is managing quick changeovers, especially when switching between different product types or packaging sizes. To optimize capping systems for fast product changeovers, manufacturers often implement modular capping systems that can be easily adjusted or reconfigured without much downtime.

For example, a modular capping machine might allow operators to swap out capping heads, conveyors, or cap alignment components quickly, minimizing the time spent on maintenance or adjustments. This ensures that production can continue smoothly, even when switching between products with different packaging requirements.

How Is Production Line Efficiency Increased with Flexible Capping Machines?

The key to increasing production line efficiency is flexibility. Flexible capping machines can handle a variety of products and packaging types without requiring major changes to the production setup. By using automated, adjustable systems, manufacturers can easily switch between different cap types and packaging sizes, making it possible to produce a wide range of products on the same line.

Additionally, by incorporating advanced technologies like torque control, cap alignment, and multi-head systems, capping machines can work faster, more accurately, and with minimal human intervention. This not only reduces the risk of errors but also enhances the overall efficiency of the production line.

This article highlights the various elements that make liquid capping machines versatile and efficient, ensuring that businesses can meet diverse packaging requirements while maintaining high production rates. By understanding the different cap types, adjusting torque settings, and optimizing machine configurations, manufacturers can enhance the reliability and speed of their liquid filling lines.