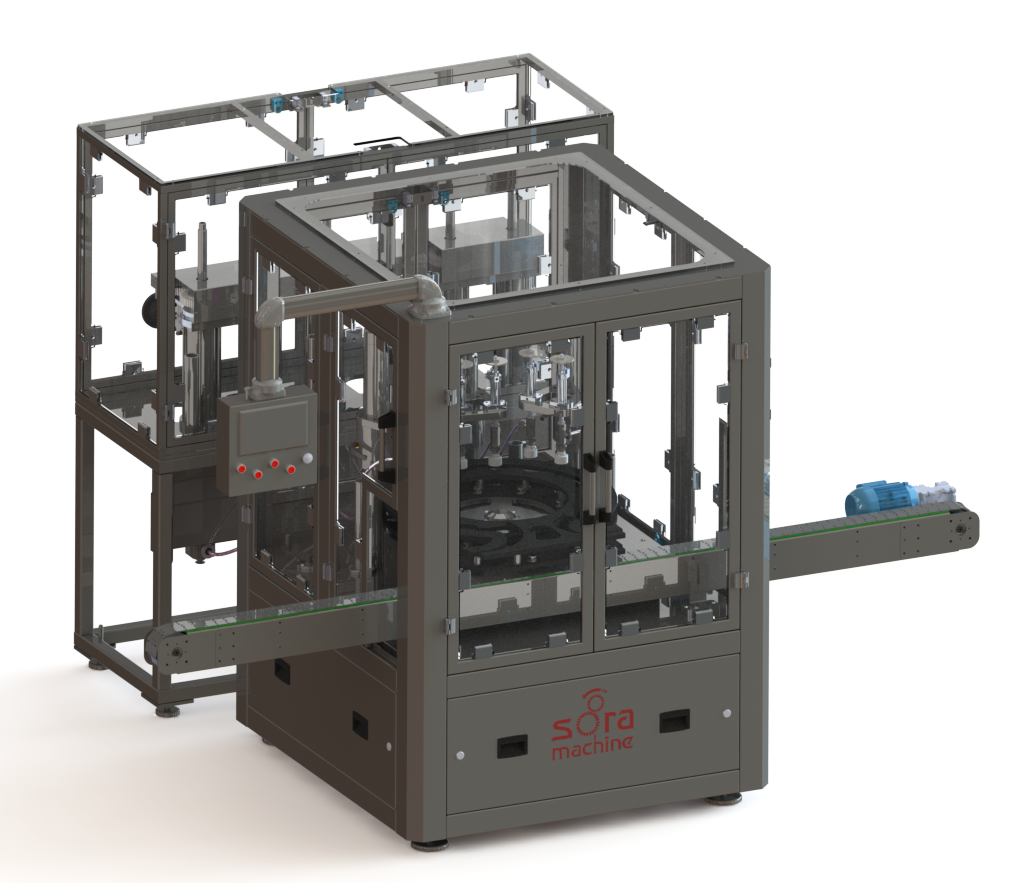

6 Heads B.O.V Liquid Filling Machine

The 6 Heads B.O.V Liquid Filling machine is a high-precision, heavy-duty industrial unit specifically engineered for the rapid and reliable dispensing of liquid products using Bag-On-Valve (B.O.V) technology. Designed for optimal throughput, this filler is constructed entirely with AISI-304 stainless steel components to ensure longevity and adherence to stringent hygienic standards. It features an adjustable dispensing cylinder range (180 – 420 ml/each) and is driven by full pneumatic working piston pressure groups, integrating a crucial ‘No Can No Fill System’ to maximize efficiency and minimize product waste.

Technical Advantages

- Adjustable Dispensing Range: The dispensing cylinder is adjustable within the range of 180 to 420 ml per each head, tailored to specific order requirements.

- Volumetric Accuracy: The filling volume is precisely regulated and set via a clock display, ensuring the measuring device scale accurately corresponds to the cylinder dispensing volume.

- Corrosion-Resistant Construction: All components critical to the filling process are manufactured using AISI-304 stainless steel.

- Chemical Compatibility: Sealing systems are constructed from high-quality materials resistant to “aggressive” products, ensuring reliable operation across diverse chemical formulations.

- Pneumatic Power: The system utilizes full pneumatic working piston pressure groups for consistent force and actuation.

- Integrated Safety Device: The unit includes a safety device engineered to prevent product out-dispensing specifically when there is no can positioned below the filling head.

Technologies Used

The 6 Heads B.O.V Liquid Filler integrates sophisticated systems for precision and control:

- Volumetric Control Mechanism: Filling volume is set digitally via a clock display and referenced against a corresponding measuring device scale linked to the cylinder dispensing volume.

- Full Pneumatic Actuation: The primary working mechanism relies on full pneumatic pressure groups, known for their reliability and low maintenance requirements in industrial environments.

- Automated Material Feed: Product is automatically supplied to the system via a dedicated diaphragm pump.

- Timing Screw Can Capturing: Precision in container handling is managed by a timing screw mechanism, ensuring accurate placement and synchronization of the cans under the filling heads.

- No Can No Fill (NCNF) System: This advanced interlock system, supported by the integrated safety device, provides failsafe operation by preventing liquid dispensation in the absence of a container.

Industrial Applications

This machine is optimized for high-volume liquid packaging requiring stringent control over volume and material compatibility. Given the machine’s robust construction and resistance features, it is well-suited for several key industrial sectors:

- Specialty Chemical and Household Products: Ideal for filling products defined as “aggressive,” benefiting from the specialized resistant sealing systems.

- Cosmetics and Personal Care: Applicable in environments demanding high throughput and the use of AISI-304 stainless steel for hygiene. (The broader context of Sora Machine suggests relevance to Cosmetics and Pharmaceutical applications).

- Industrial Filling Solutions: Specifically designed for industrial applications where quick filling and precision volume control (180 – 420 ml range) are paramount.

Operational Benefits

The machine’s design delivers tangible benefits to production line management and quality control:

- Enhanced Throughput: The unit was specifically developed to make quick filling possible, leading to improved overall production efficiency.

- Waste and Cost Reduction: The No Can No Fill System combined with the integrated safety device eliminates product dispensing errors, dramatically reducing spillage and subsequent material loss.

- Rapid Setup and Changeover: The design incorporates features for easy weight adjustment and an easy and adjustable can height setting, minimizing downtime during product or container changes.

- Simplified Operation: The utilization of a clock display for volume setting and automatic product pumping via a diaphragm pump simplifies operator interaction and ensures consistent performance.

Differentiation

The 6 Heads B.O.V Liquid Filling machine distinguishes itself through its focus on material quality, precision, and integrated safety:

- Robust Material Mandate: The commitment to using AISI-304 stainless steel for all components ensures superior hygiene and durability compared to systems utilizing lower-grade materials.

- Aggressive Product Resilience: The sealing systems, manufactured from high-quality materials resistant to aggressive products, provide reliable operation where many standard fillers would experience accelerated degradation.

- Comprehensive Safety Integration: The dual safety approach—featuring both a standard safety device preventing out-dispensing when a can is absent, and the overriding ‘No Can No Fill System’—offers a higher level of operational security and product preservation.

- Dedicated Speed Optimization: The machine is explicitly specifically developed to make quick filling, indicating optimized cycle mechanics for maximum filling velocity.