Why Your Coding Line Needs a Stabilized Ink-Jet Side Band System

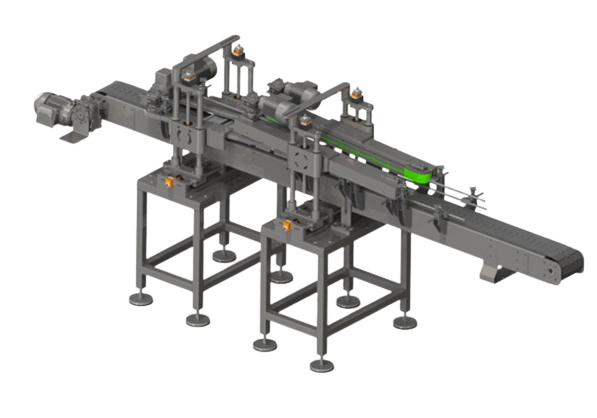

The coding phase is often where production quality is most visible to your end customer, and I’ve seen how a slight wobble in a container can turn a batch of clear expiry dates into an unreadable mess. This Ink-Jet Side Band System acts as the steady hand for your production line, using PU material bottle holder belts to grip each container firmly as it passes the inkjet head. It is designed to bridge the gap between high-speed filling and the final packaging stage, ensuring that your codes are as professional as the product inside the can.

Maximizing Print Clarity: Key Technical Gains for Your Conveyor

- Hazardous Zone Reliability: You can integrate this system directly into your most sensitive areas; every motor, sensor, and control panel is fully ex-proof (ATEX) for both Zone 1 and Zone 2.

- Interference-Free Performance: To ensure your inkjet electronics aren’t disrupted by electrical build-up, all scrolls and guide rail covers are made from specialized anti-static materials.

- Material Longevity: The frame is built from AISI 304 stainless steel, which I recommend for any facility that requires frequent washdowns or handles mildly corrosive materials.

- Energy Efficiency: Operating with a 0.25 kw motor and a total consumption of roughly 1 kw, this system provides the necessary torque for heavy-duty containers without driving up your utility costs.

The Engineering Behind the Grip: PU Belts and ATEX Safety

The system relies on a hybrid mechanic and electronic working principle that prioritizes stability. By utilizing polyurethane (PU) for the holder belts, the machine provides a high-friction grip that prevents containers from rotating or shifting during the printing window. This is paired with an electronic control system that uses ATEX-certified PLC and buttons, ensuring that even the smallest electronic signal is safe within an environment containing flammable propellants or vapors.

Where to Deploy the Side Band System for High-Risk Environments

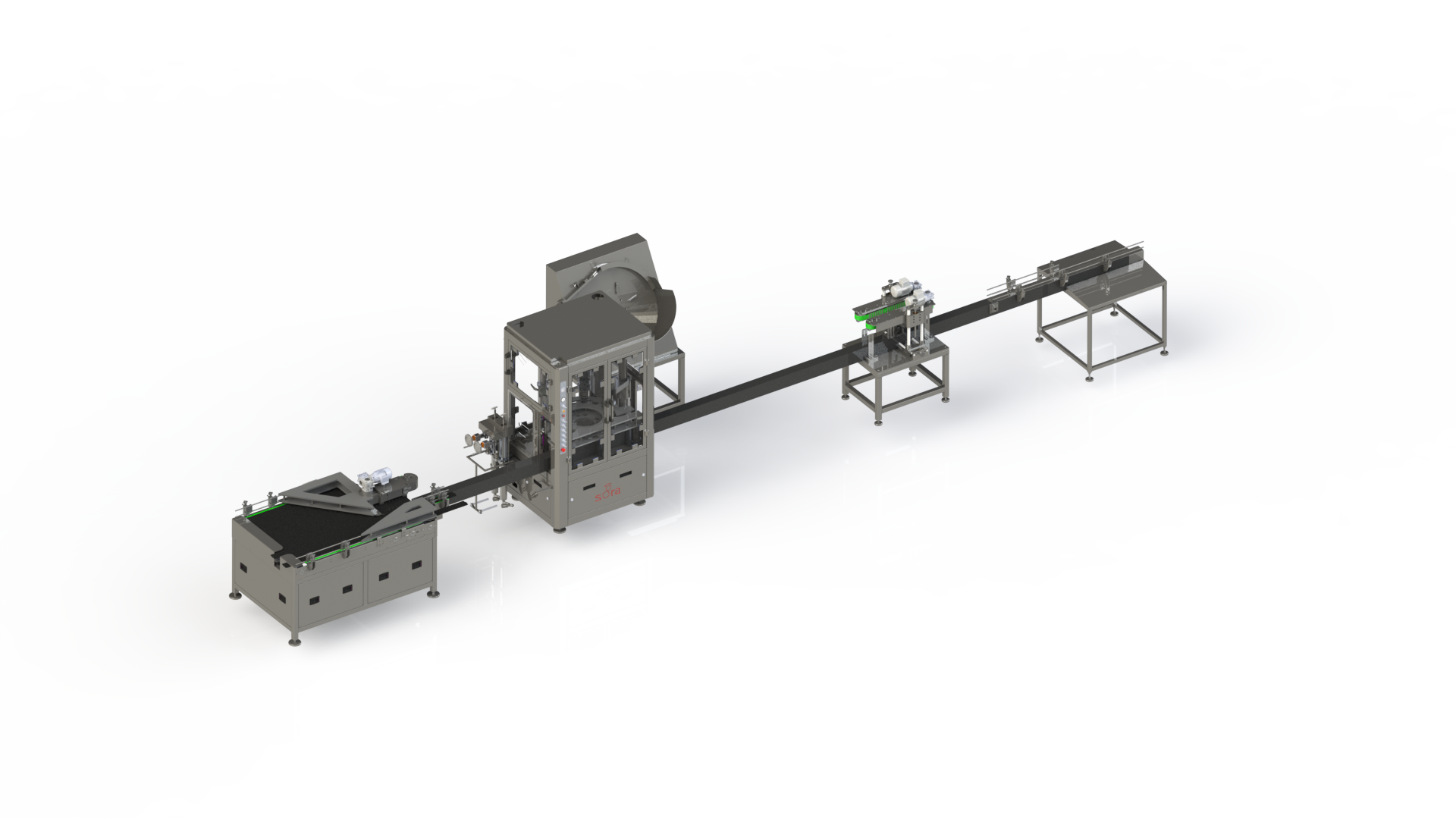

If you are running a facility focused on aerosol cosmetics, pharmaceuticals, or industrial lubricants, you know that safety zones are non-negotiable. Because this system is fully ATEX compliant from the motors down to the buttons, it is the ideal choice for lines where flammable gases are present. It fits perfectly into monoblock or linear filling setups that require side-coding on the body of the container rather than the bottom.

Practical Operational Gains for Your Maintenance Team

One of the biggest headaches for floor managers is the maintenance of “change parts” on the line. Since this system uses AISI 304 stainless steel and anti-static plastic covers, it resists the typical wear and tear that leads to part failure. You’ll find that the 220V setup is easy to integrate into your existing electrical grid, and the compact motor size means it won’t overwhelm your conveyor’s structural integrity. It’s a “set and forget” unit that allows your operators to focus on the inkjet settings rather than constantly adjusting the container guides.

- 304 SS construction

- 0,25 kw motor

- Bottle holder belts: PU Material

- Electricity Comsumption:1 kw (roughly)

- Working system: mechanic, electronic