Who Are Semi-Automatic Aerosol Filling Machines Ideal For?

Semi-automatic aerosol filling machines are specifically designed for companies conducting new product tests in a laboratory setting, performing pilot production runs, or those with limited production capacity. They are frequently chosen in the following areas:

- Personal care and cosmetic products (e.g., deodorants, hair sprays)

- Industrial spray solutions

- Pet care and medical products

- Seasonal or special series productions

These machines deliver high precision and ease of use, even for low-volume production needs.

What Are the Technical Specifications of the Semi-Automatic System?

The semi-automatic filling machine model stands out with its user-friendly interface, stainless steel body, and flexible format compatibility. Here’s a summary of its technical details:

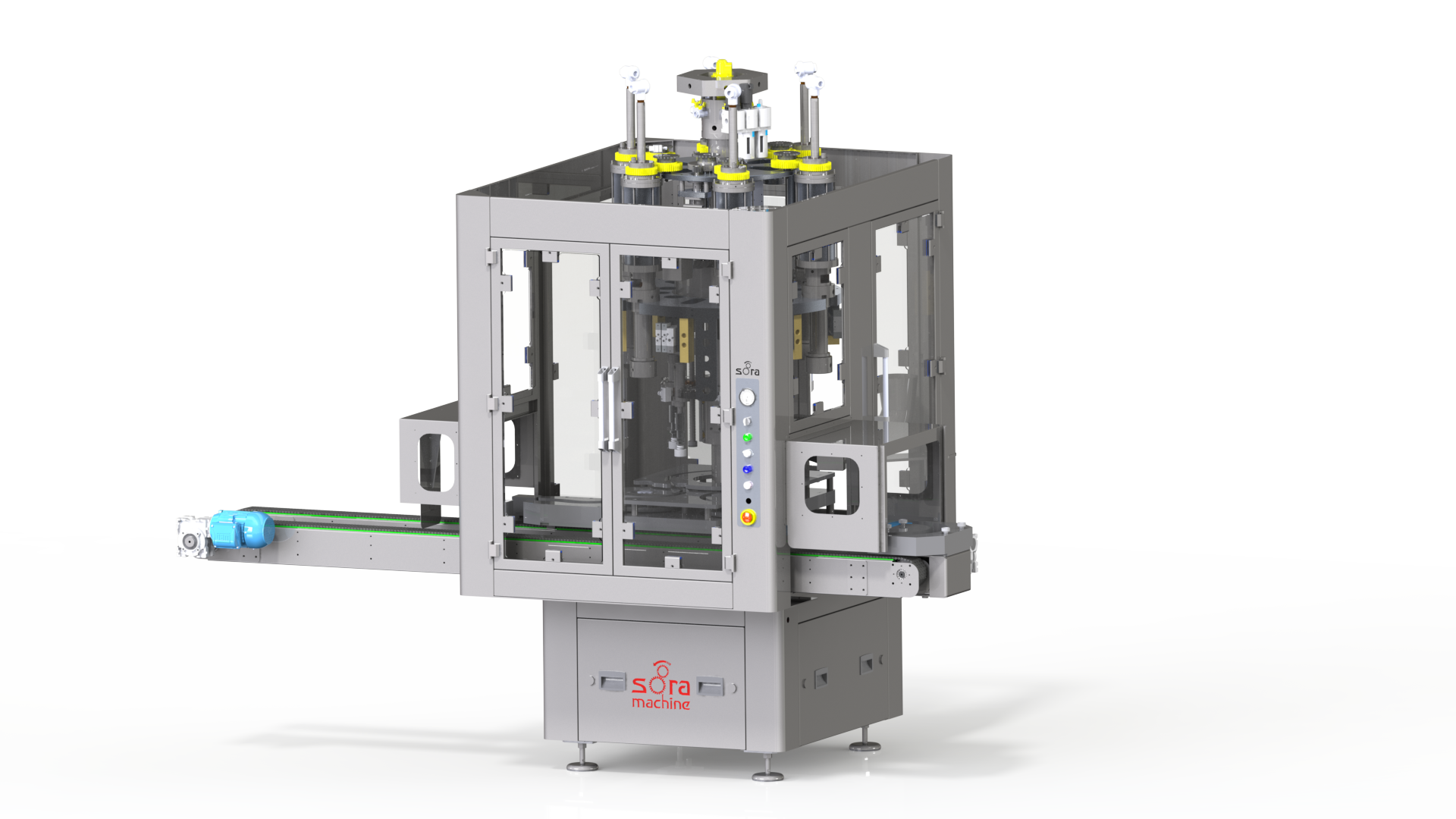

What Advantages Does the 6-Head Propellant Filling Machine Offer?

For manufacturers looking to scale beyond semi-automatic systems, Sora Machine offers a 6-head propellant filling machine that combines high speed with robust safety standards. This system can fill up to 30 cans per minute and is fully compatible with various gas types, including LPG and DME.

Technical Specifications:

What Underpins Sora Machine’s Design Philosophy?

Sora Machine is not just a machine manufacturer; we are a partner that provides complete production solutions. Our machines are designed with:

- Easy-to-clean construction for hygienic production.

- Fast and simple format changes.

- CE-compliant safety systems for operator protection.

- Support from advanced technical service and remote assistance options.

All our products are developed in full compliance with GMP and ISO standards.