What is a Gas House and Why is It Necessary in Aerosol Filling Lines?

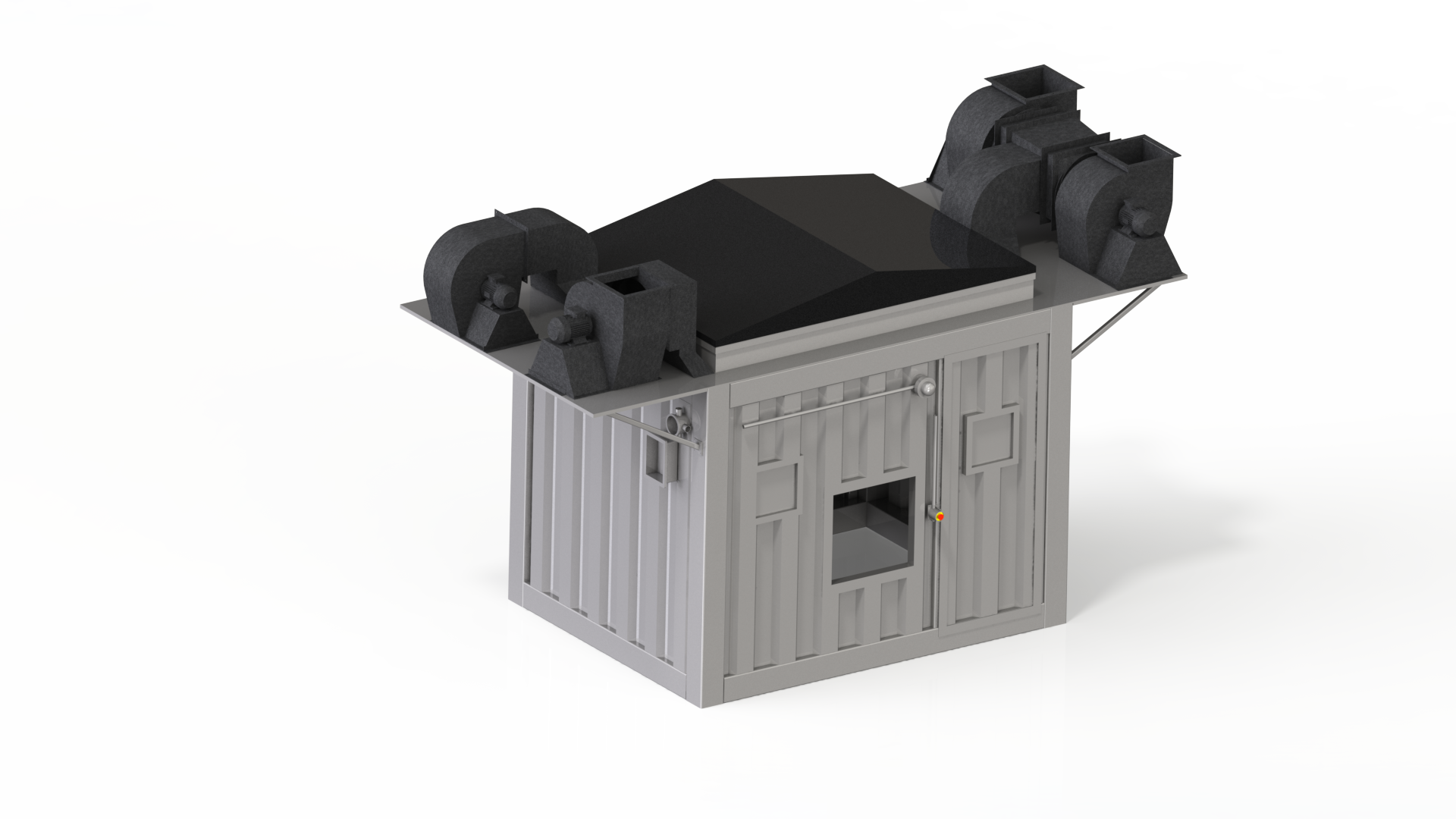

A Gas House is a specialized safety cabinet used in aerosol filling lines that ensures the controlled, safe, and isolated processing of hazardous, flammable, and volatile gases. It is vital in systems that operate with propellant gases like LPG, providing protection against leakage risks. Sora Machine’s Gas House solution is designed in compliance with EN14470-1 and ATEX standards, elevating both operator and environmental safety to the highest level.

Which Safety Standards Does the Sora Machine Gas House System Meet?

The Gas House is manufactured in accordance with global safety regulations, especially European directives:

- ATEX Zone Class I and II compliant structure

- EN14470-1 standards for gaseous environment control

- Stainless steel body for fire and corrosion resistance

- Ventilation and exhaust systems for maximum gas evacuation

- Explosion-proof pressure relief valves

- Automatic monitoring infrastructure with gas detectors

Thanks to this equipment and design, the system creates a safe operating environment in production facilities.

How Is the Gas House System Integrated into Aerosol Filling Lines?

Sora Machine’s Gas House solution can be integrated into aerosol filling lines in a modular fashion. The system is compatible with the following operational areas:

- 6-head or 12-head filling systems

- Laboratory-type semi-automatic systems

- Fully automatic high-capacity lines

The Gas House is typically positioned in the gas cylinder section of the filling line, and gas is supplied to the filling line via special connections. Throughout this process, parameters such as internal pressure, gas leakage, and temperature are continuously monitored.

What Advantages Does Using a Gas House Offer?

Using a Gas House provides significant advantages not only in terms of safety but also in terms of production line continuity and legal compliance:

- Minimizes leakage risks, preventing industrial accidents.

- Ensures operator and equipment safety, reducing maintenance costs.

- Complies with local and international safety standards.

- Centralizes gas management, enabling systematic monitoring.

- Provides the ability to respond early to fire and explosion risks.

Additionally, with this unit integrated into the automation system, automatic shutdown and alarm systems are activated whenever a gas-related risk is detected on the production line.

In Which Production Areas Is the Gas House System Preferred?

Gas House units are preferred not only in the aerosol sector but also in other gas-based production processes:

- Cosmetic product manufacturing (deodorant, hair spray, perfume)

- Medical aerosol products (MDI solutions)

- Household care products (room spray, surface cleaner)

- Industrial lubricant and solvent-based spray production

Especially in lines where propellant filling is intensive, safety solutions like the Gas House are indispensable.