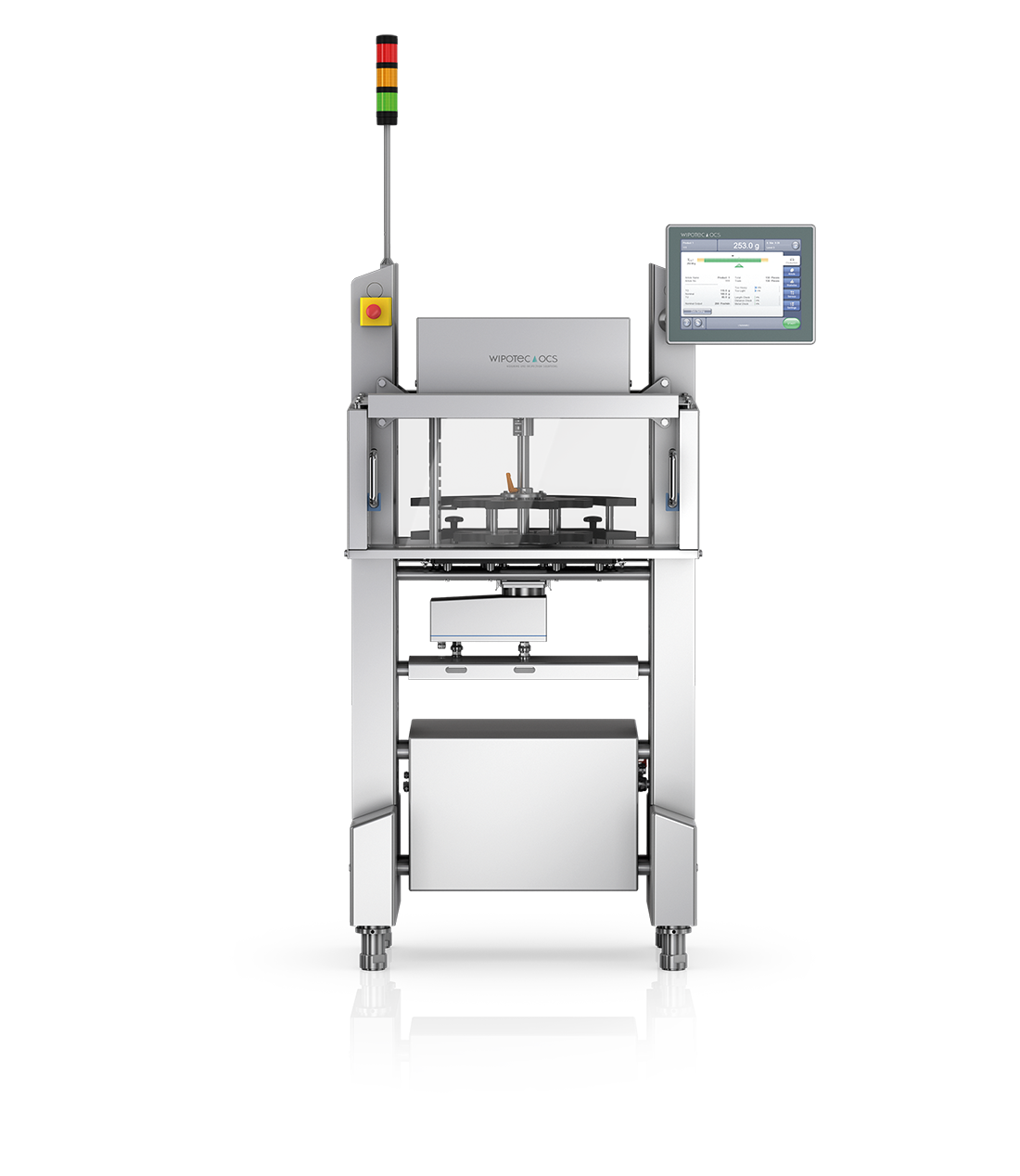

CHECKWEIGHER (MODEL: CW-DPCW1)

CW-DPCW1 Checkweigher is a dedicated, high-speed weighing instrument crucial for quality assurance in automated industrial filling lines. Designed to integrate seamlessly into environments such as aerosol production lines, the system ensures container mass accuracy across a wide range. The unit is capable of operating at speeds Up to 80 pieces per minute (PPM) and handles product capacities from 5 grams up to 1,000 grams. Central to its function is the core weighing device supplied by Mettler Toledo, combined with surrounding equipment engineered by SORA MACHINE, offering dependable measurement performance. The system maintains a high measuring accuracy of ±%0.5 and is managed via a dedicated 8-inch TFT touch screen.

Technical Advantages

- High Throughput: Engineered for continuous production environments, achieving weighing speeds of Up to 80 pcs per minute.

- Precision Accuracy: Offers a consistent measuring accuracy of ±%0.5 across its operational range.

- Broad Capacity Range: Accommodates lightweight to medium-weight products, covering 5 g to 1,000 g.

- Integrated Premium Weighing Component: Utilizes a core weighing device provided by Mettler Toledo.

- Customizable Controls: Features an 8’’ TFT touch screen that allows operators to adjust critical parameters, including vibration filters, accuracy settings, and capacity features.

Used Technologies

The CW-DPCW1 employs advanced industrial components and precise control methodologies tailored for dynamic weighing:

- Weighing Technology: The system integrates a specialized Mettler Toledo weighing device, which is the foundational technology for accurate mass measurement.

- Human-Machine Interface (HMI): Control and monitoring are facilitated through a Touch 256 color 8’’ TFT Screen. This interface provides the operator with control over system settings such as adjustable vibration filters, which can be fine-tuned to counter environmental interference that might otherwise affect accuracy.

- Product Handling Constraint: The system operates on a dedicated band that processes only one product type at a time. When switching products, the wheel requires a stop and adjustment based on the new product’s weight and control value.

- Safety Classification: The equipment has a non-ex-proof classification, which is a critical consideration for installation environments.

Industrial Applications

The Checkweigher CW-DPCW1 is primarily utilized in sectors requiring mandatory and accurate mass control during high-speed packaging:

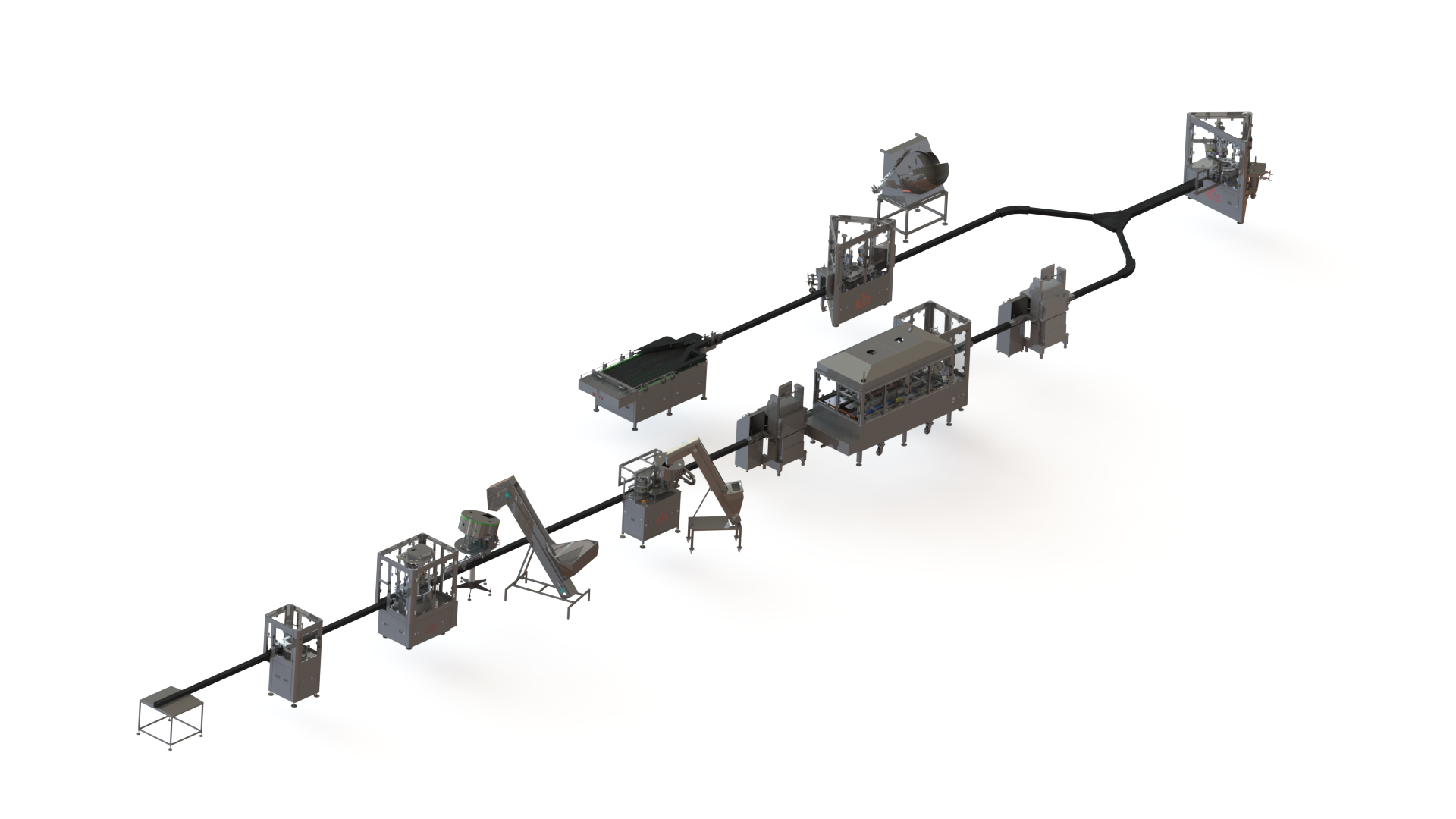

- Aerosol Filling Lines: The system is explicitly identified as a component within comprehensive aerosol filling machine solutions, often integrated alongside propellant filling machines and collecting tables.

- Pharmaceutical and Cosmetic Production: Applicable to filling lines where strict control over active ingredient weight or fill volume (within the 5g to 1,000g capacity) is essential for regulatory compliance.

- General Industrial Filling: Used in turnkey solutions for general industrial filling machines where end-of-line quality control for mass is required.

Operational Benefits

For factory managers, procurement departments, and engineers, the CW-DPCW1 provides specific operational efficiencies and quality guarantees:

- Reliable Quality Gate: Ensures that all products leaving the line adhere to specified weight tolerance (±%0.5), reducing costly under-filled or over-filled packages.

- Simplified Operation and Setup: The 8’’ TFT touch screen allows for quick, on-the-fly adjustment of critical operational parameters, improving flexibility and minimizing downtime during calibration.

- Component Confidence: Leveraging a Mettler Toledo core device provides high confidence in the reliability and consistency of the weighing component.

- Process Optimization Capability: The adjustable vibration filters enable operators to maximize measurement accuracy by compensating for factory floor disturbances or specific environmental factors.

Technical Specification Table

- Only device is provided from a Mettler Toledo. Other equipment belongs SORA MACHINE

- Model: CW-DPCW1

- Working Speed: Up to 80 pcs per min.

- Capacity:5-1.000 g

- Measuring Accuracy : ± %0,5

- Screen: Touch 256 color 8’’ TFT

- Adjustable vibration filters, accuracy, capacity feature on screen

- Accuracy might depend on environmental factors

- Only one product can be passed and controlled through band. Once the product is changed, wheel

needs to be stopped and needs to be adjusted according to weight and control value of new product. - System is non-ex-proof