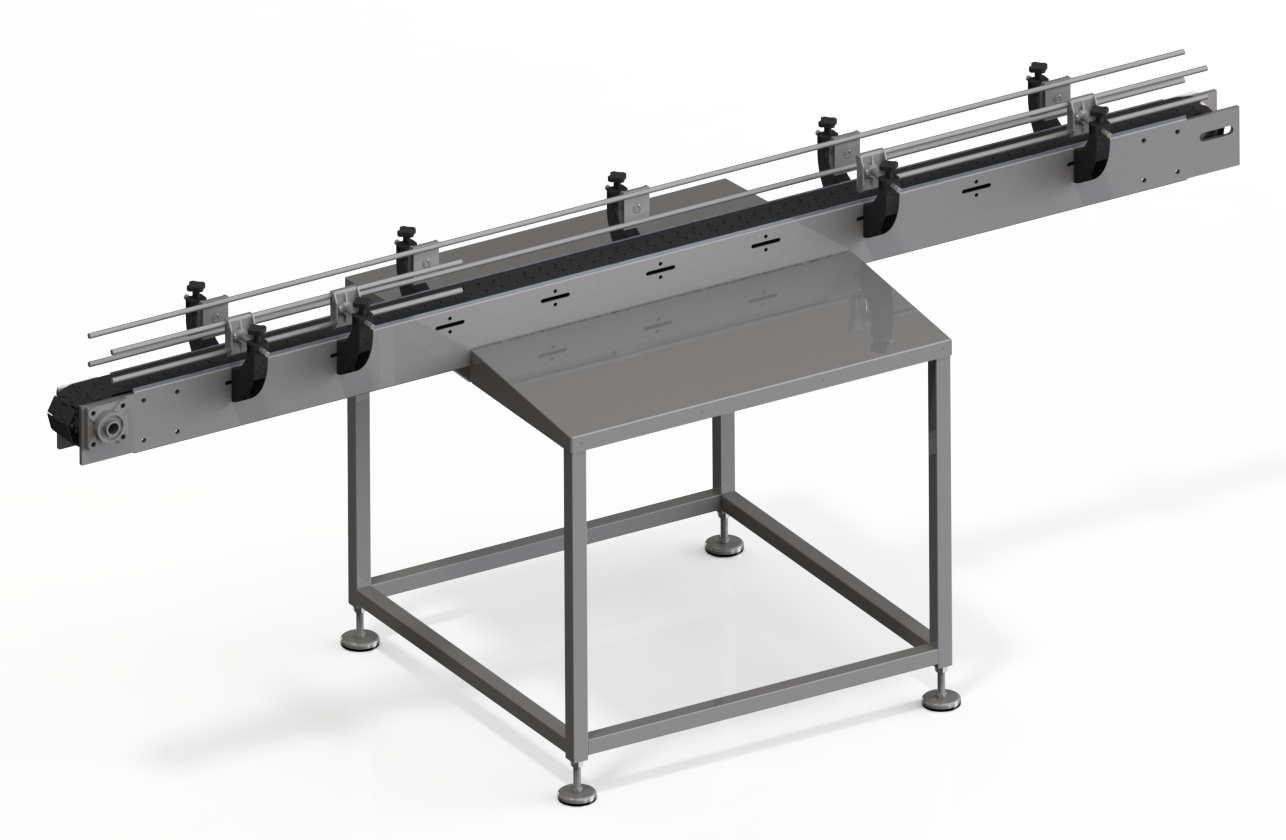

COLLECTING TABLE

The Collecting Table is a robust, high-performance end-of-line component engineered for efficient container staging and accumulation in demanding production environments. Constructed entirely with 304 SS (Stainless Steel) materials, this unit features a single tray collection zone designed for hygiene and durability. Its mechanical operation is managed by a superior gearbox drive system, which deliberately eliminates the use of traditional chains or belts, significantly enhancing reliability and reducing long-term maintenance needs. The design is reversible and inherently flexible, capable of handling a variety of round bottles with easy change over functionality.

Technical Advantages

- Premium 304 SS Construction: Ensures exceptional corrosion resistance, longevity, and compliance with stringent sanitation standards, utilizing 304 SS construction for the main structure.

- Gearbox Drive System: Achieves precise, reliable motion transfer without chains or belts, minimizing wear parts and eliminating the complexities of routine tensioning and lubrication.

- Integrated Protection: Features 4 stainless steel covers specifically designed to protect critical internal components, including the motor, gearbox, and frame structure, from the external operating environment.

- Durable Guidance System: The rail mechanism utilizes a combination of stainless steel and poly rail mounted with L-bracket, ensuring smooth container flow and high wear resistance.

- Structural Integrity: Built on a stainless steel frame and topped with a stainless steel top, reflecting a consistently robust design standard.

- Adjustable Integration: Includes adjustable height capability for seamless alignment with upstream and downstream conveyor systems.

Used Technologies

The Collecting Table incorporates core mechanical and material technologies optimized for manufacturing uptime and reliability:

- Direct Gearbox Power Transmission: This advanced drive technology ensures positive, non-slip operation, offering superior efficiency and durability compared to traditional chain or belt systems.

- High-Grade Material Engineering: The extensive use of 304 Stainless Steel across the construction, frame, top surface, and protective covers provides a foundation of material strength and cleanliness necessary for regulated industries.

- Versatile Handling Mechanism: The system is engineered to be flexible, accommodating a variety of round bottles. Paired with adjustable height features and a sophisticated stainless steel and poly rail, it optimizes line versatility and minimizes the operational time required for easy change over.

Industrial Applications

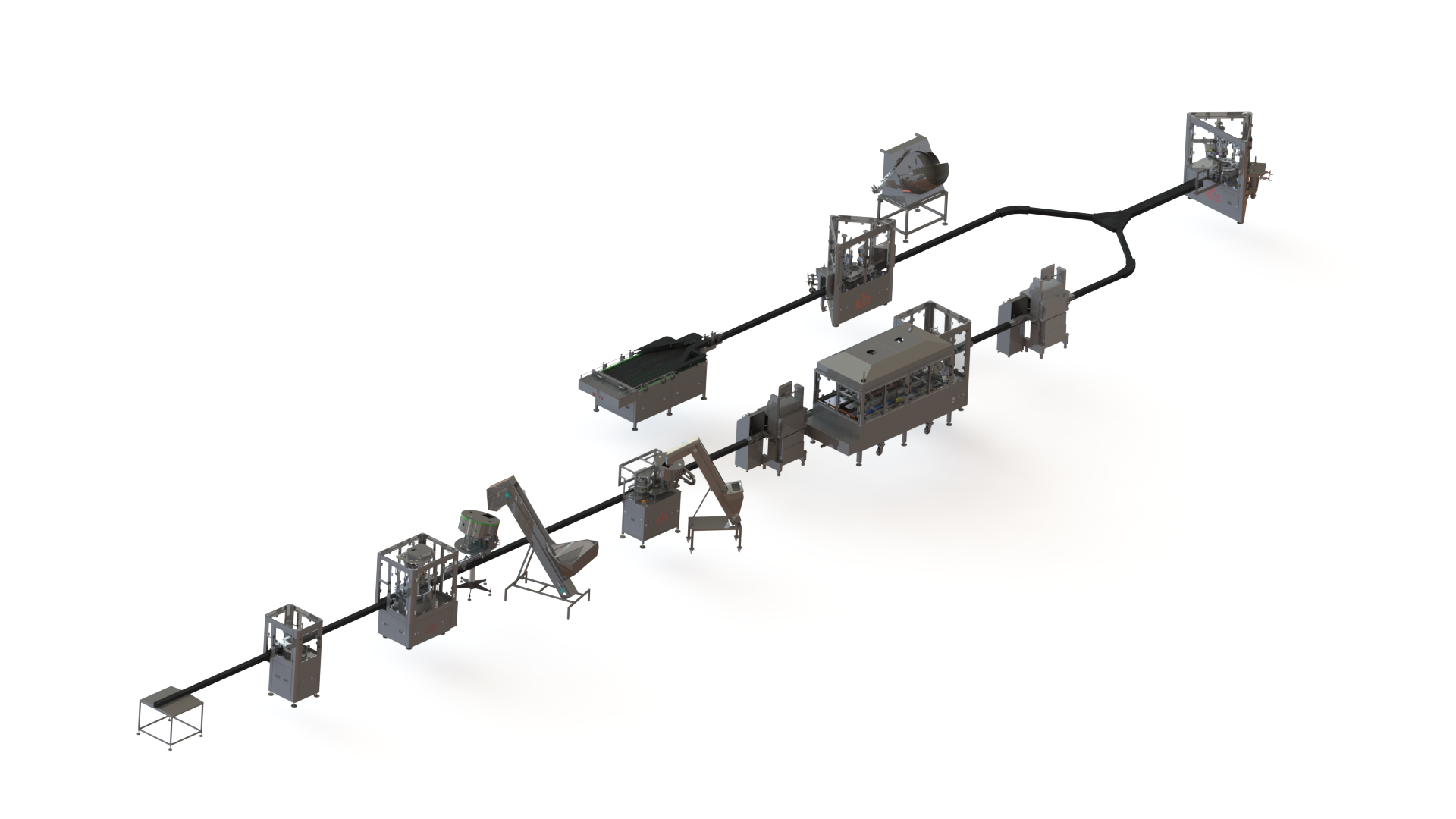

This Collecting Table is an indispensable solution for post-filling and end-of-line accumulation in various industries requiring high-speed and sanitary handling of containers. Relevant industrial sectors that utilize similar equipment from the supplier include:

- Aerosol Filling: Listed as a critical component alongside aerosol filling machinery.

- Pharmaceutical: Suitable for regulated environments requiring 304 SS construction and robust design.

- Cosmetics: Ideal for the high-volume collection and staging of finished products.

- Liquid Filling Machines: Used for general bottling lines handling a variety of round bottles.

- Packing & Palletizing: Functions as a critical buffer zone before final packaging or palletizing stages.

Operational Benefits

The design priorities of the Collecting Table translate directly into maximized operational efficiency and reduced total cost of ownership:

- Maximum Flexibility: The unit’s reversible capability and capacity to run a variety of round bottles ensure rapid integration and adaptation across changing production needs and diverse product SKUs.

- Minimized Downtime: The easy to change over feature allows for quick transition between product formats, maximizing production hours.

- Reduced Maintenance Overhead: The gearbox drive design eliminates the maintenance burden associated with chains or belts, contributing to higher Mean Time Between Failure (MTBF).

- Guaranteed Component Protection: The 4 stainless steel covers safeguard the motor and gearbox, ensuring machine longevity and reducing risk of foreign object debris ingress.

- High Uptime: The inherently robust design and 304 SS construction ensure sustained performance in continuous operation environments.