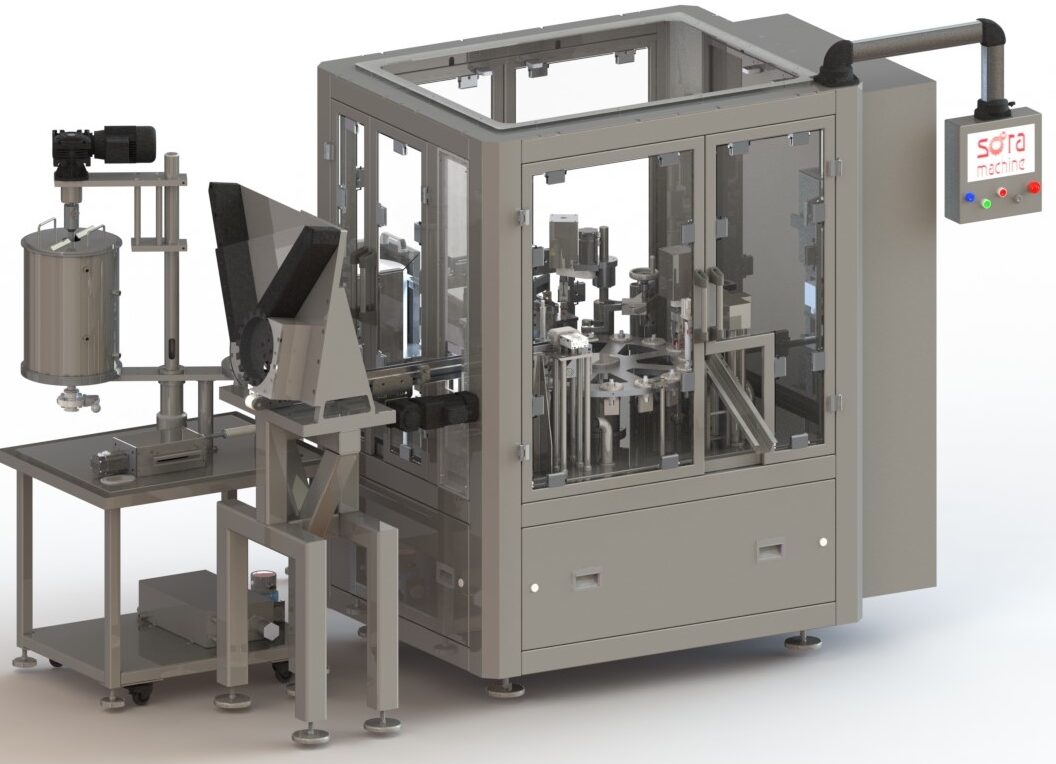

What is the Lipgloss Filling Up to 40 BPM Machine?

Developed by Sora Machine, the Lipgloss Filling Up to 40 BPM is a specialized make up filling machines designed to safely, hygienically, and precisely fill highly viscous cosmetic products. With a production capacity of up to 40 units per minute, it offers an ideal solution for medium-scale production lines. This system is particularly optimized to accommodate the viscous nature of lipgloss formulations.

Which Cosmetic Products Is It Suitable For?

This machine is primarily suitable for lipgloss and similar semi-liquid formulations of comparable density. Example products include:

- Glossy lip products

- Lightly pigmented liquid lipsticks

- Lip care serums

- Low-volume, high-viscosity serums

It provides high repeatability and precision for these types of products, which are often challenging to fill with standard systems.

What Technologies Does It Utilize?

The lipgloss filling machine is equipped with Sora Machine’s advanced technologies. Its core features include:

- Piston filling system (adjustable according to viscosity)

- No-drip nozzles (prevents product dripping)

- Vacuum scraping system

- PLC-controlled touchscreen panel

- Stainless steel body and food-contact compliant parts

- Filling tolerance with ±1% accuracy

These features enable both high-quality production and compliance with GMP standards.

How Does It Integrate with Monoblock Lipgloss Filling Station?

This filling system is designed to work in full integration with Sora Machine’s Monoblock Lipgloss Filling Station. The station’s contributions include:

- Servo motor-controlled filling volume and speed adjustment

- Pneumatic cylinder for nozzle up-and-down movement

- “No bottle, no fill” principle to prevent waste

- Easy-to-clean modular design

- Design suitable for automatic format change

Thanks to the monoblock structure, processes like product feeding, filling, and cap placement are performed smoothly from a single station.

Is It Easy for Operators to Use?

Yes, this machine features a user-friendly PLC screen interface. Operators can:

- Adjust filling quantity, flow rate, and timing

- Quickly switch between different product types

- Instantly monitor fault or warning systems

- Complete cleaning and maintenance procedures in a short time

This significantly reduces training time and increases efficiency on the production line.

Does It Comply with Hygiene and Cleaning Standards?

Hygiene is a top priority in the machine’s design. In compliance with GMP (Good Manufacturing Practices):

- All product-contact surfaces are made from stainless steel.

- It can be integrated with an automatic cleaning-in-place (CIP) system.

- Pistons and nozzles can be easily dismantled and sterilized.

- The vacuum system minimizes product leaks.

This design ensures both product safety and streamlines the cleaning process.

How Is Filling Quality and Consistency Ensured?

The machine’s piston system automatically adjusts to product consistency and operates with ±1% accuracy for each fill. Additionally:

- Back-suction nozzles provide extra protection against dripping.

- A vacuum-assisted scraper prevents residue on the nozzle rim.

- A controlled flow system prevents foaming.

This ensures consistent quality with every fill.

Which Auxiliary Systems Can It Be Integrated With?

The machine can be configured to integrate into a fully automatic production line. Compatible systems include:

- Monoblock Lipgloss Filling Station: Combines product feeding, filling, and cap placement on a single platform.

By integrating these systems, every stage of the production line is automated, saving labor and time.

What Does Technical Service and Support Cover?

Sora Machine offers comprehensive support for this model, as with all its systems:

- On-site installation and commissioning services

- Operator training

- Remote technical support

- Spare parts supply and maintenance planning

Furthermore, customized engineering solutions for production needs are also part of Sora Machine’s services.