What is a Mascara Filling Machine and How Does Sora Machine Offer Solutions for This Process?

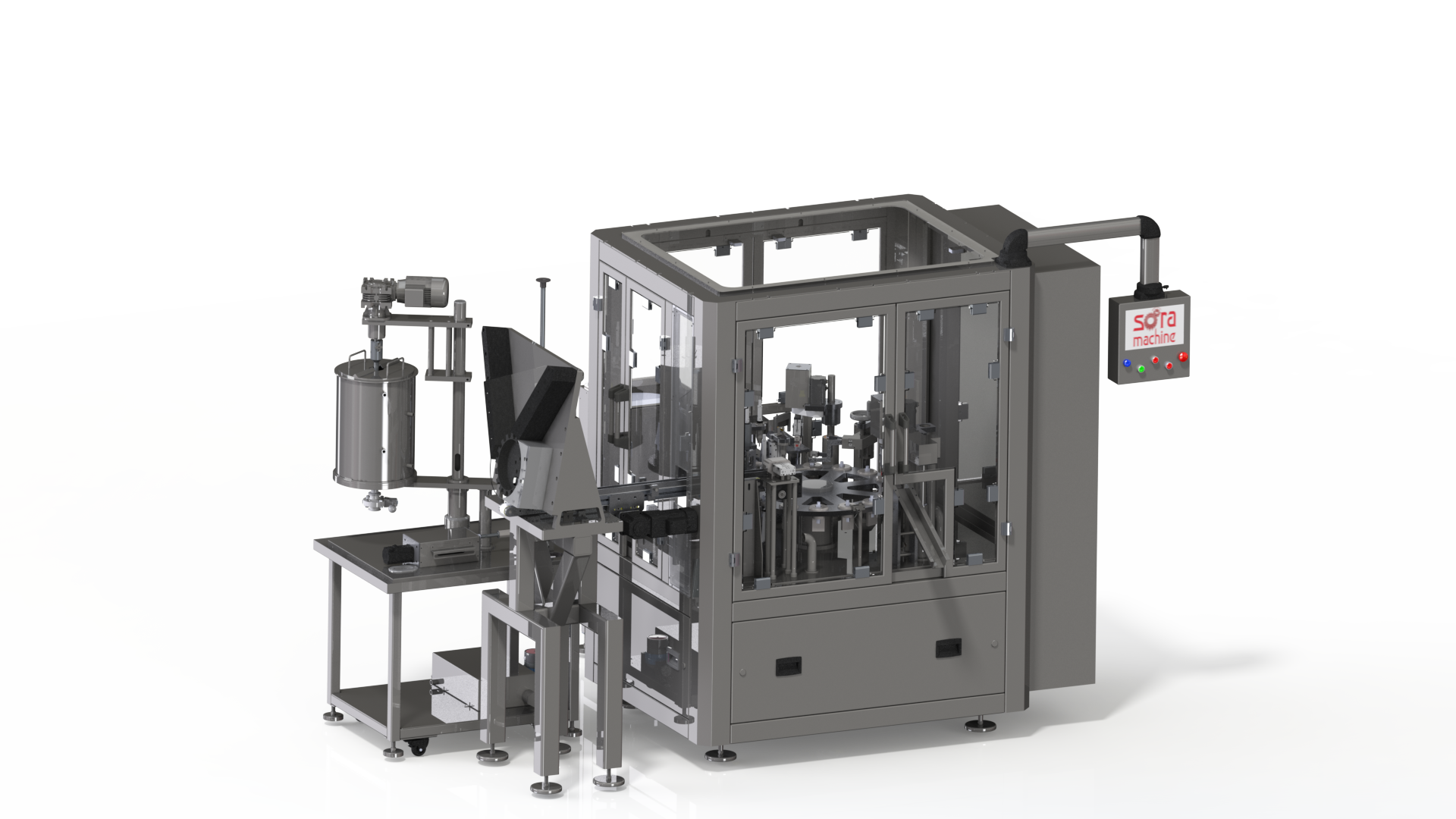

Mascara filling machines are systems developed to perform the filling of mascara automatically and hygienically, making it one of the most delicate production processes in the cosmetics industry. Sora Machine’s mascara filling solution, offering a capacity of up to 40 fills per minute, is optimized to work seamlessly even with high-viscosity formulas.

For cosmetic products with special consistencies like mascara, filling accuracy, formula preservation, and production speed must be managed simultaneously. At this point, Sora Machine, with its high-precision volumetric filling technology, enables manufacturers to achieve fast and stable production that meets their quality standards.

Which Production Volume is a 40 BPM Mascara Filling Machine Suitable For?

This model, offering performance of up to 40 fills per minute, is ideal for medium to high-scale cosmetic manufacturers. The system provides sufficient production tempo for brands targeting thousands of products daily, shortening filling times while also helping to reduce labor costs.

Its design, suitable for high-viscosity formulas (e.g., fiber-infused, highly volumizing, or waterproof mascaras), is a significant factor that makes this machine stand out in the market.

What Features Does the Sora Machine Mascara Filling Solution Come Equipped With?

This machine is not just a filling system, but an integrated production solution. It comes standard with the following equipment:

- Servo-controlled volumetric filling unit

- Brush and cap feeding conveyor

- Capping device

- Bottle discharge unit

- 30L stainless steel pressure tank

- Mitsubishi brand touchscreen control panel

The user-friendly design of this system ensures that the production process is easy, flexible, and safe for operators.

What Advantages Does a Monoblock Filling Station Provide in Mascara Production?

Sora Machine’s monoblock mascara filling station is integrated to perform filling, brush insertion, and capping operations on a single platform. This design saves space while minimizing operator intervention and reducing errors.

The monoblock system:

- Optimizes production time.

- Meets GMP standards thanks to stainless steel in contact areas.

- Allows for easy format changes for different packaging types.

For brands that want to offer high speed and quality simultaneously, this system is a solution that will be at the heart of their production.

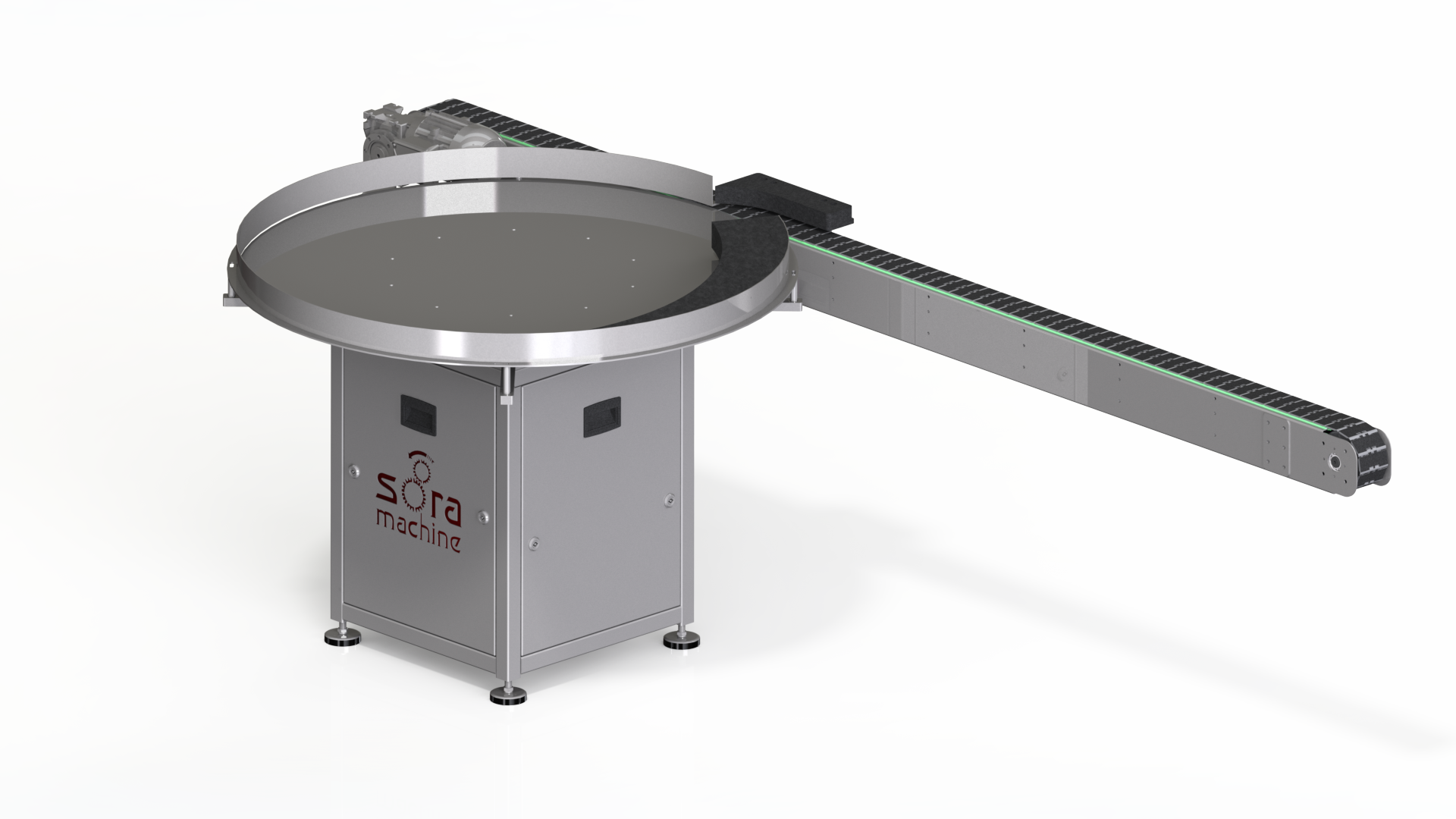

What is a Rotary Feeding Table and Why is it Used?

To ensure proper flow and timing in production lines, bottles entering the filling machine must be fed regularly. At this point, a rotary feeding table offers a practical solution where operators can randomly place bottles, but the system aligns them and directs them to the production line.

Sora Machine’s rotary feeding table:

- Is compatible with round bottles.

- Can be adapted to different production lines due to adjustable height.

- Offers low maintenance with gearbox drive.

- Is suitable for hygienic production environments with its stainless steel surface.

This table is critical for ensuring a continuous and stable feed at the starting point of your production line.

How Does a Rotary Collecting Table Support the Production Process?

Once filling and capping operations are complete, products need to be collected regularly and directed to subsequent steps (labeling, packaging, etc.). A rotary collecting table provides an ergonomic and organized exit that operators can easily access.

Sora Machine’s rotative collecting table:

- Ensures bottles are collected together without tipping.

- Offers installation flexibility with its reversible feature.

- Provides long life and low maintenance by using a gearbox instead of chains or belts.

- Is easy to clean and GMP compliant due to its stainless steel construction.

This equipment at the end of the production line is a system that completes the process and maintains flow without losing speed.

How Do All These Systems Work Together Harmoniously?

Sora Machine’s production philosophy is to offer not just a single machine, but integrated, modular, and flexible line solutions. The mascara filling machine ensures a continuous product flow with the rotary feeding table, while enabling quick and neat product retrieval at the end of production thanks to the rotary collecting table. The monoblock station, at the heart of production, carries out filling and capping operations in an integrated manner.

These systems:

- Reduce time loss.

- Minimize human intervention.

- Standardize product quality.

- Lower operational costs.