What Do Nail Polish Filling Machines Do?

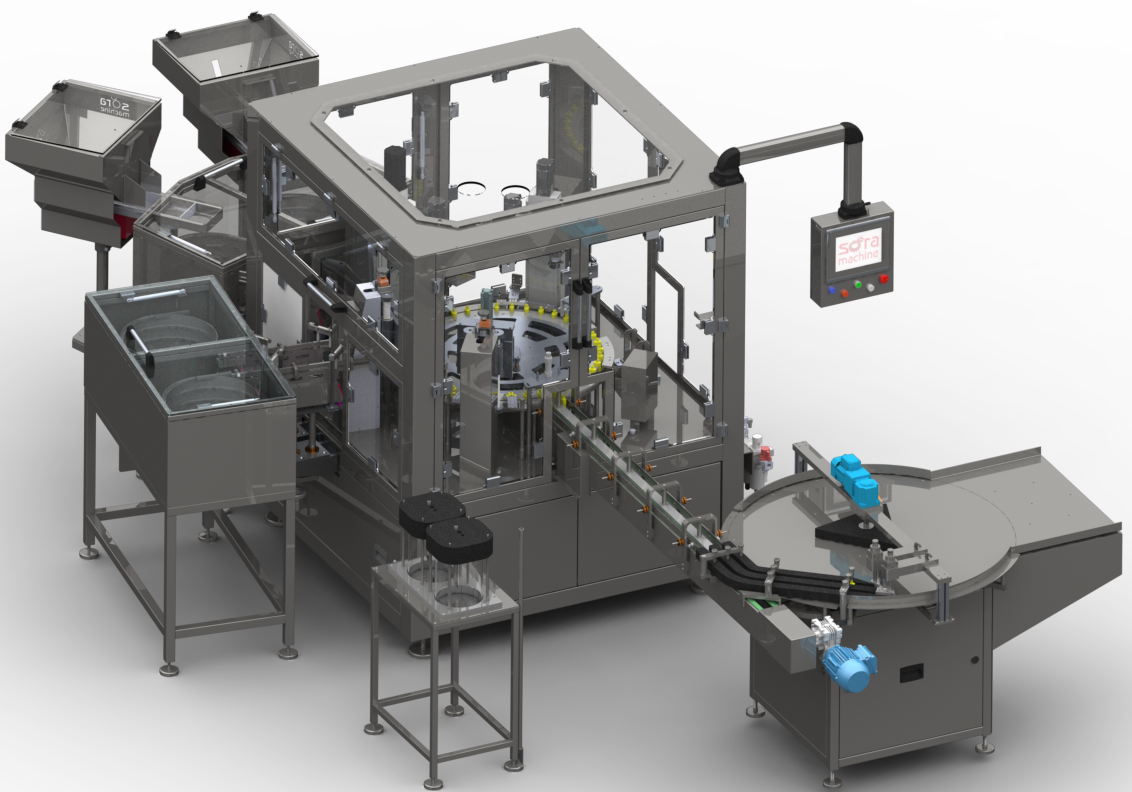

Nail polish filling machines automatically, precisely, and hygienically bottle high-viscosity cosmetic products such as nail polish, top coats, and similar items. These machines are specifically developed for filling operations into small-volume glass or plastic packaging. Sora Machine’s solution in this area is a high-precision automation system capable of operating at production speeds of up to 40 BPM (bottles per minute).

Which Products Are Compatible with the Sora Machine Nail Polish Filling Unit?

This system works with high efficiency, especially for the following product types:

- Classic nail polish formulas

- Gel-based nail polishes

- Clear and colored protective nail products

- Nail hardener formulations

- Glitter or particle-infused polishes

To enable smooth filling of these varying viscosity products, the machine is equipped with piston or peristaltic pump options.

Which Packaging Formats Does This System Support?

Sora Machine’s nail polish filling machine, operating at up to 40 BPM, is compatible with the following packaging types:

- Glass bottles with volumes of 5 ml, 10 ml, and 15 ml

- Small-volume plastic packaging with narrow necks

- Bottles with integrated or subsequently placed brush caps

Regardless of the packaging shape, the system has a flexible structure that can be adjusted according to bottle height and cap type.

What Are the Stages of the Filling Process?

Sora Machine’s filling machines in this segment have the following operational steps:

- Bottle feeding: Bottles are fed into the system manually or via a rotary feeder.

- Precise filling: The nail polish formula is transferred into the bottle with adjustable dosage.

- Brush and cap placement: Caps with integrated brushes are positioned automatically.

- Cap tightening: Caps are secured using a torque-controlled tightening mechanism.

- Output and collection: Bottles are conveyed forward to the next process.

Why Should Nail Polish Manufacturers Prefer This System?

Consistency, visual quality, and minimum waste rates are among the most critical issues in the production of nail polish and similar cosmetic products. The advantages offered by Sora Machine’s system include:

- Grammage deviations are prevented thanks to high-precision filling.

- Air bubble formation is minimized, preserving product aesthetics.

- Error-free capping is ensured with automatic brush placement.

- Space-saving due to its compact design.

- Short changeover times offer quick transitions between different bottle and formulation types.

Why is Sora Machine a Reliable Partner in This Field?

Sora Machine is an engineering brand known for its experience in makeup filling lines and application engineering, creating customized solutions for each client. It aims to meet all manufacturers’ needs with its product quality, technical support strength, and international service capacity.

- Over 20 years of experience

- R&D-backed engineering solutions

- European standard production quality

- Advanced automation options

- Global after-sales support network

How Does the Purchasing and Technical Support Process Work?

Sora Machine not only provides machines to its customers but also offers project consultancy and post-installation training support. You can contact them directly to get a quote for a nail polish filling machine, receive support for customized configurations for your production line, or obtain technical information.