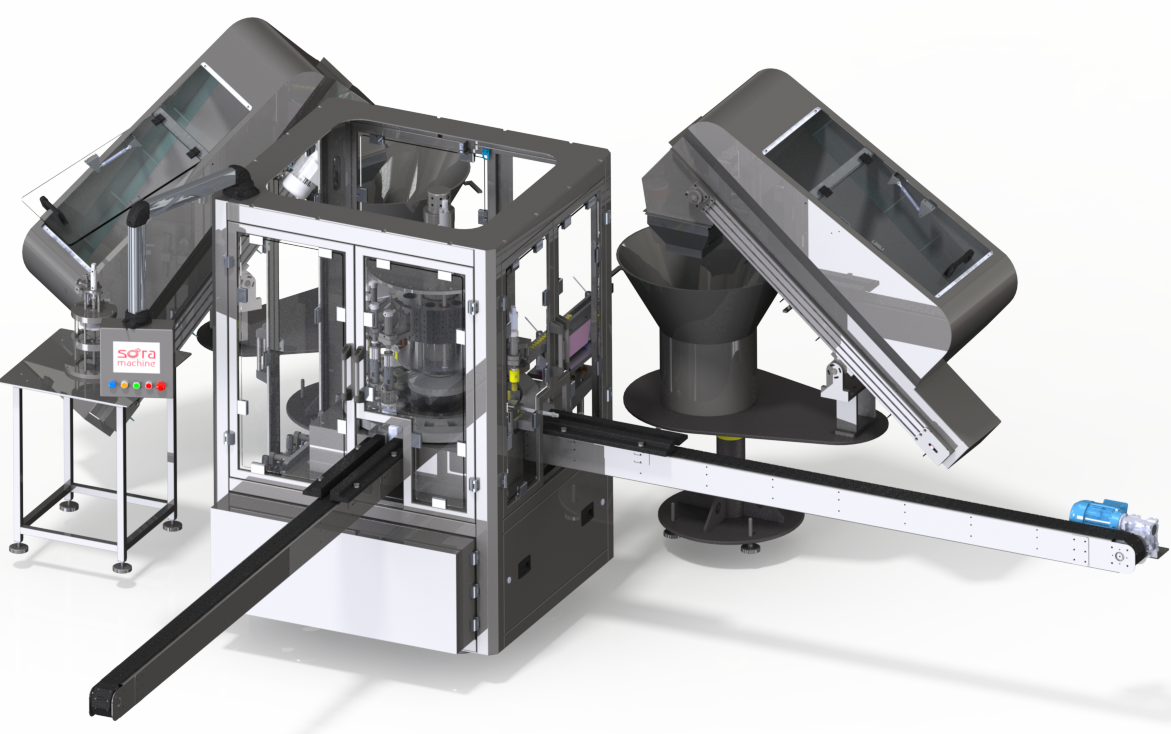

What is the Monoblock Perfume Filling Machine?

Sora Machine’s Monoblock Perfume Filling Machine is a fully automatic system that combines the filling, valve insertion, and capping processes for perfumes and similar liquid cosmetic products into a single, compact unit. This integrated design saves valuable production line space while delivering high efficiency and adhering to stringent hygiene standards.

What Product Types Is It Compatible With?

The Monoblock system is particularly suitable for the production of the following liquid products:

- Alcohol-based perfumes

- Colognes

- Low-viscosity liquids like body sprays

- Aroma and essential oil-based cosmetic solutions

All product-contact surfaces are made from stainless steel, ensuring compliance with hygiene criteria in the cosmetics and personal care sectors.

What Makes This System Different?

This model distinguishes itself from other perfume filling machines through its key features:

- Integrated Valve and Cap Placement: Valve and cap application are performed automatically after filling, ensuring an uninterrupted production process.

- Precise Vacuum Filling Technology: Fills products without foaming, preventing waste, and achieving an accuracy of ±1%.

- Compact Design: All process steps are housed within a single body, minimizing operator requirements and floor space.

What Are Its Technical Specifications?

Manufactured to Sora Machine’s high technical standards, this machine is equipped with the following specifications:

- Filling System: Vacuum-based

- Capacity: Up to 30 bottles per minute

- Material: AISI 304 and 316 stainless steel

- Electrical and Pneumatic Components: Global brands like SIEMENS, OMRON, SMC, FESTO

- Bottle Compatibility: Adaptable to bottles of various diameters and heights

- Control Unit: PLC-based digital interface (touchscreen)

- Safety Systems: Emergency stop options with a clutching mechanism and bottle detection sensors

Does It Offer Ease of Operation?

Yes, Monoblock Perfume Filling Machine with Valve & Cap Placing systems are known for enabling high efficiency with minimal operator involvement:

- Format changes can be performed quickly.

- Operator training time is short; management is easily done via the screen.

- Compatible with CIP (clean-in-place) systems for maintenance and cleaning.

- Contact surfaces can be disassembled without tools, providing a hygiene advantage.

Which Manufacturers Is It Suitable For?

This machine is particularly suitable for:

- Perfume brands with medium to high-volume production.

- Specialized cosmetic workshops.

- Businesses aiming to produce under GMP and ISO standards.