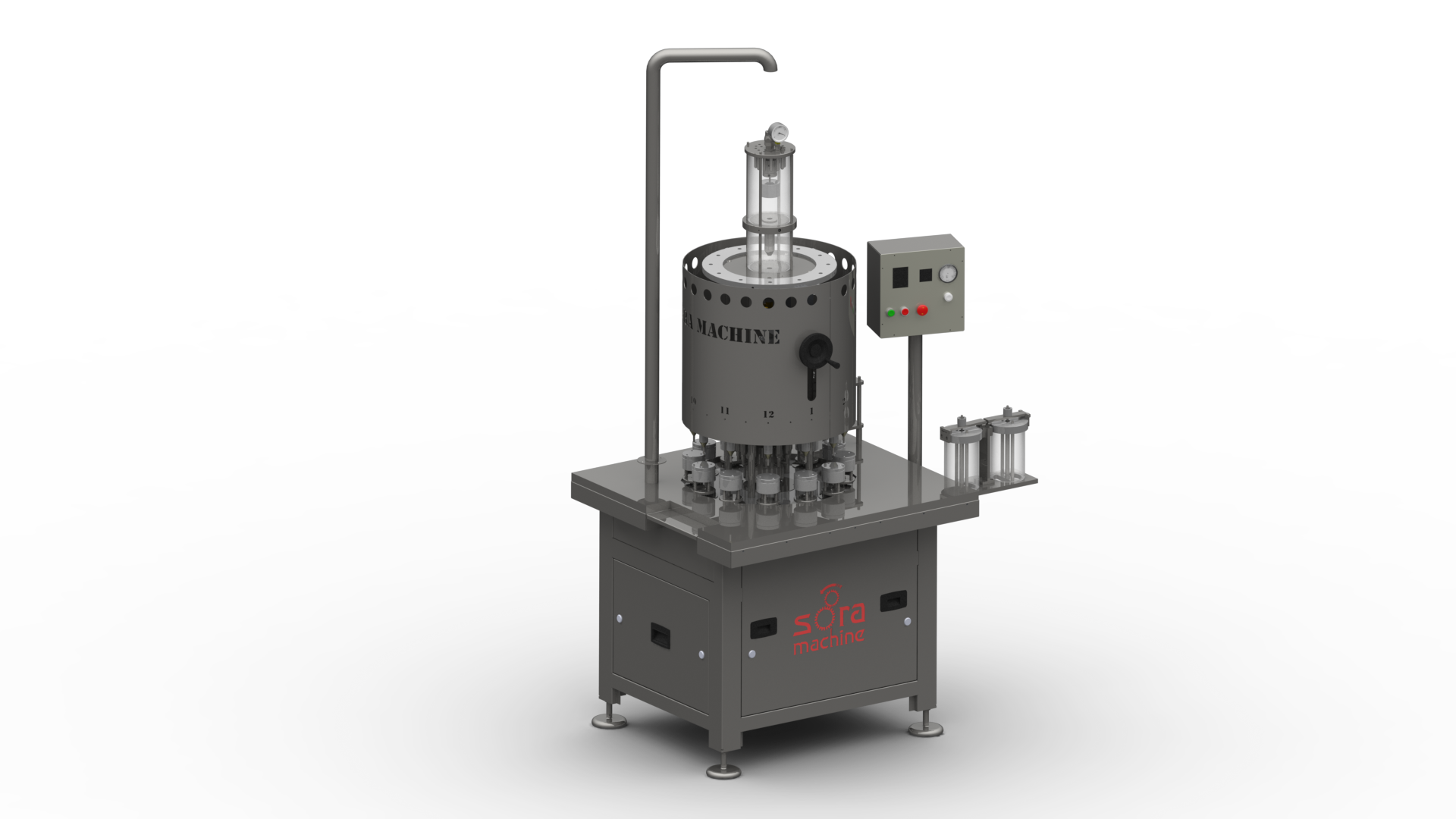

What is a Rotary Perfume Filling Machine and For Which Productions Is It Preferred?

A rotary (rotary type) perfume filling machine is a multi-station automatic system specifically designed for medium and high-volume production lines. It ensures high-speed, precise, and consistent filling of perfumes and similar low-viscosity liquids into bottles. It offers a homogeneous, error-free, and efficient filling process for both aesthetically packaged products and industrial-scale productions.

How Does the Rotary System Differ from Other Filling Systems?

Sora Machine’s rotary filling line stands out due to the following advantages:

- Continuous motion system: Production flows uninterrupted, with filling continuing without pauses.

- Multi-station structure: Steps like filling, cap placement, and capping can occur simultaneously.

- Higher BPM (Bottles Per Minute): Provides greater bottle processing capacity per minute.

- Fully automatic structure: Minimizes human intervention, increasing production continuity.

This structure maximizes efficiency in mass production-oriented cosmetic facilities, going beyond classic linear systems.

Which Products Is It Suitable For?

The rotary system is ideal for the following product groups:

- Perfumes (alcohol-based and alcohol-free)

- Room fragrances

- Colognes

- Body sprays

- After-shave and aromatic liquids

The system can be configured to suit glass, plastic, or metal bottles.

What Functions Do Other Integrated Units Provide to the System?

The rotary perfume filling system can be integrated into Sora Machine’s monoblock perfume lines or modular automation systems. It is typically used in conjunction with the following units:

- Rotary feeding unit (bottle sorter)

- Vacuum filling module

- Crimping – valve sealing unit

- Sprayer (spray pump) placement

- Labeling machine

- Coding and batch marking system

All these modules work in full synchronization. They can be added or configured as needed.

Which Sectors Prefer It?

Rotary perfume filling machines are widely used in the following sectors:

- Cosmetics

- Personal care products

- Perfumery

- Hotel/SPA product filling facilities

- Private label manufacturers

High-volume production facilities prefer rotary systems for serial filling and packaging.

Does It Provide Time and Cost Advantages in Production Processes?

Yes, absolutely. Thanks to the rotary system’s continuous motion mechanism, the following benefits are achieved:

- Time savings: Multiple operations are completed in each cycle.

- Operational efficiency: Labor requirements decrease, and waste rates are reduced.

- Energy efficiency: High-volume production in a short time.

- Rapid depreciation: The return on investment period is shortened.

All these advantages allow businesses to increase their production capacity while keeping costs under control.