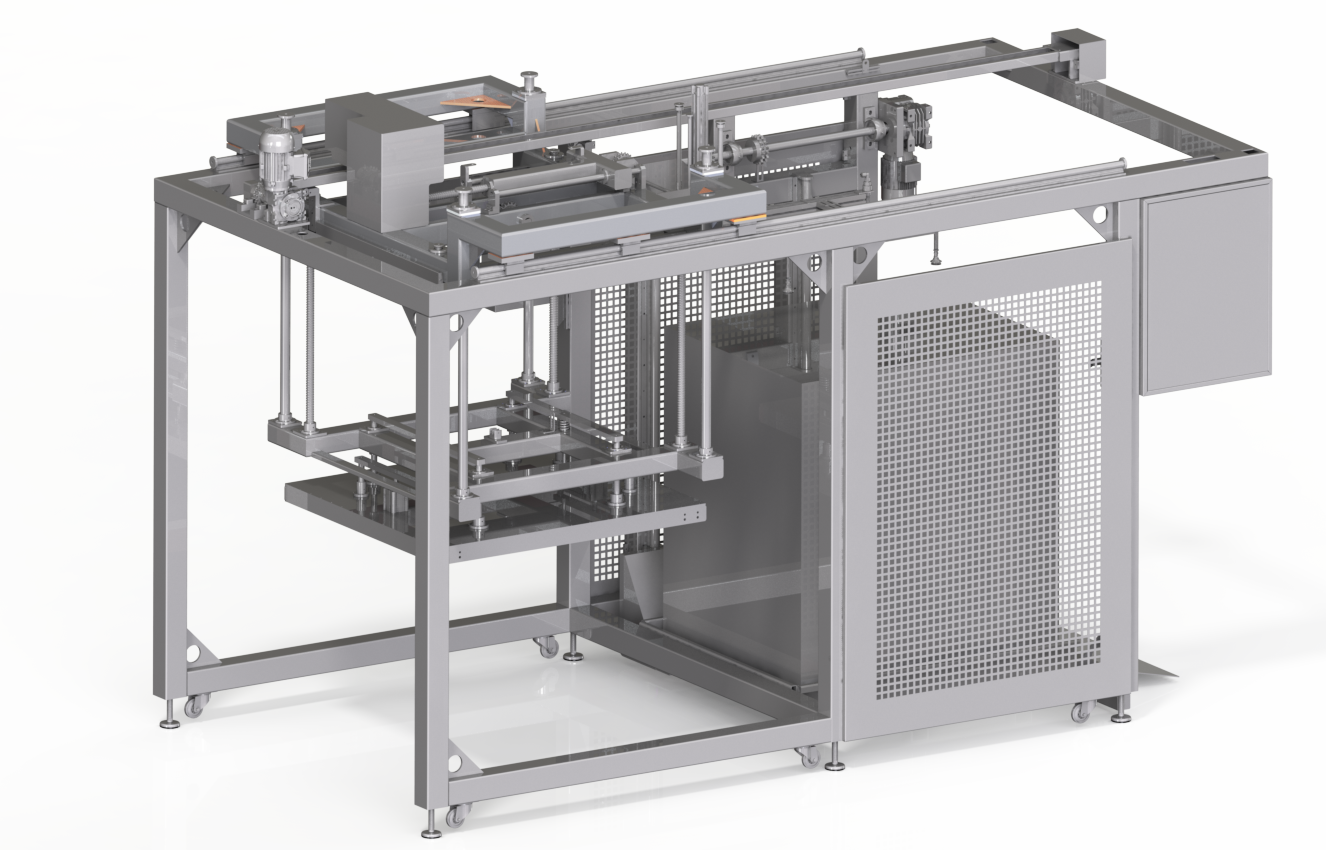

Soramachine DEPALLETIZER – Automatic Pallet Unloading System

The Depalletizer, produced by Sora Machine, automates the process of unloading cans or bottles from pallets, particularly in aerosol production lines, thereby increasing labor efficiency and accelerating production processes.

Sora Machine Depalletizer Technical Specifications

- Conveyor Height: Standard 950 mm (±50 mm)

- Electrical Requirement: 3 phase, 400V, 50Hz

- Energy Consumption: 5 kW

- Machine Dimensions (WxDxH): 1500×2500×950 mm

- Machine Weight: Approximately 1200 kg

- Structure Material: 304 L stainless steel

- PLC Control System: Automatic control and monitoring

- Conveyor Motor: Ex-proof (ATEX certified)

- Table Type: Magnetic or vacuum options

- Vacuum Separator: Cardboard separation system

- HMI Control Panel: User-friendly interface

- Synchronous Operation System: Compatible with the feeding table

Sora Machine Depalletizer Operating Principle

- Pallet Unloading: The operator manually places the cans/bottles from the pallet onto the conveyor.

- Can Conveying: The conveyor system automatically transfers the cans/bottles to the production line.

- Can Separation: The vacuum separator or magnetic system separates the cans/bottles from each other, ensuring a smooth flow.

- Synchronization: The machine works in sync with the feeding table, delivering the cans/bottles in the correct position.

Sora Machine Depalletizer Advantages

- Increased Efficiency: The automatic unloading process reduces manual labor and increases production speed.

- Safety: Ex-proof motors and ATEX certified components ensure safe use in explosive environments.

- Flexibility: Magnetic and vacuum table options allow compatibility with various can/bottle types.

- Easy Integration: The PLC control system and HMI panel offer easy integration into existing production lines.

Sora Machine Depalletizer Application Areas

- Aerosol Production: Production lines for products such as deodorant, perfume, and cleaning sprays.

- Cosmetic Sector: Production processes for shampoo, hair spray, and body spray.

- Chemical Sector: Production lines for cleaning products and spray formulations.