Your Guide to Aerosol Filling, B.O.V Systems, and Turnkey Solutions

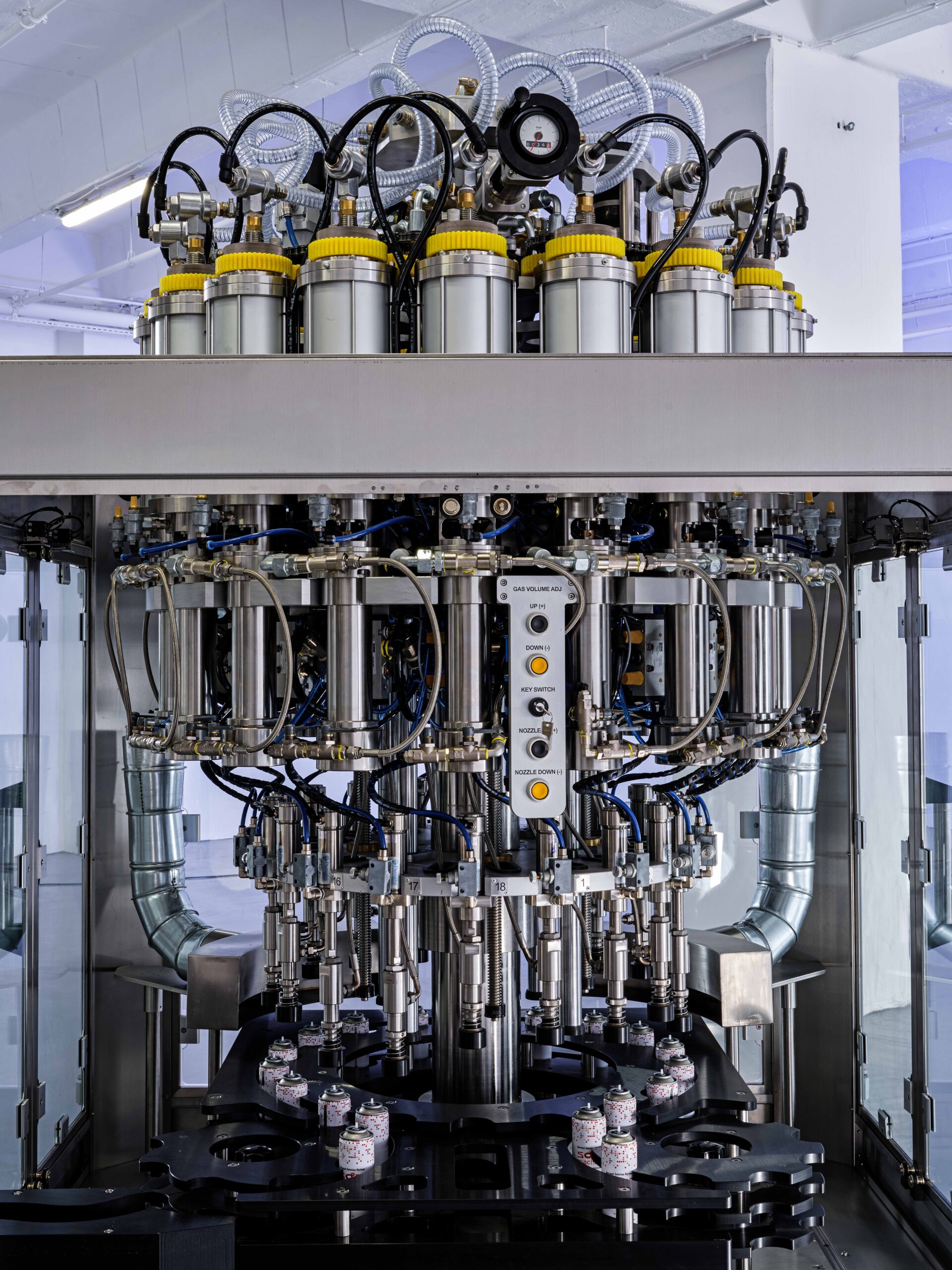

Our production lines feature piston, peristaltic, and weight-controlled filling systems. The choice depends entirely on the product’s characteristics. For example, piston systems are ideal for high-viscosity products, while peristaltic pumps are best for low-volume, precision fills. This minimizes waste and ensures every container gets exactly the right amount.

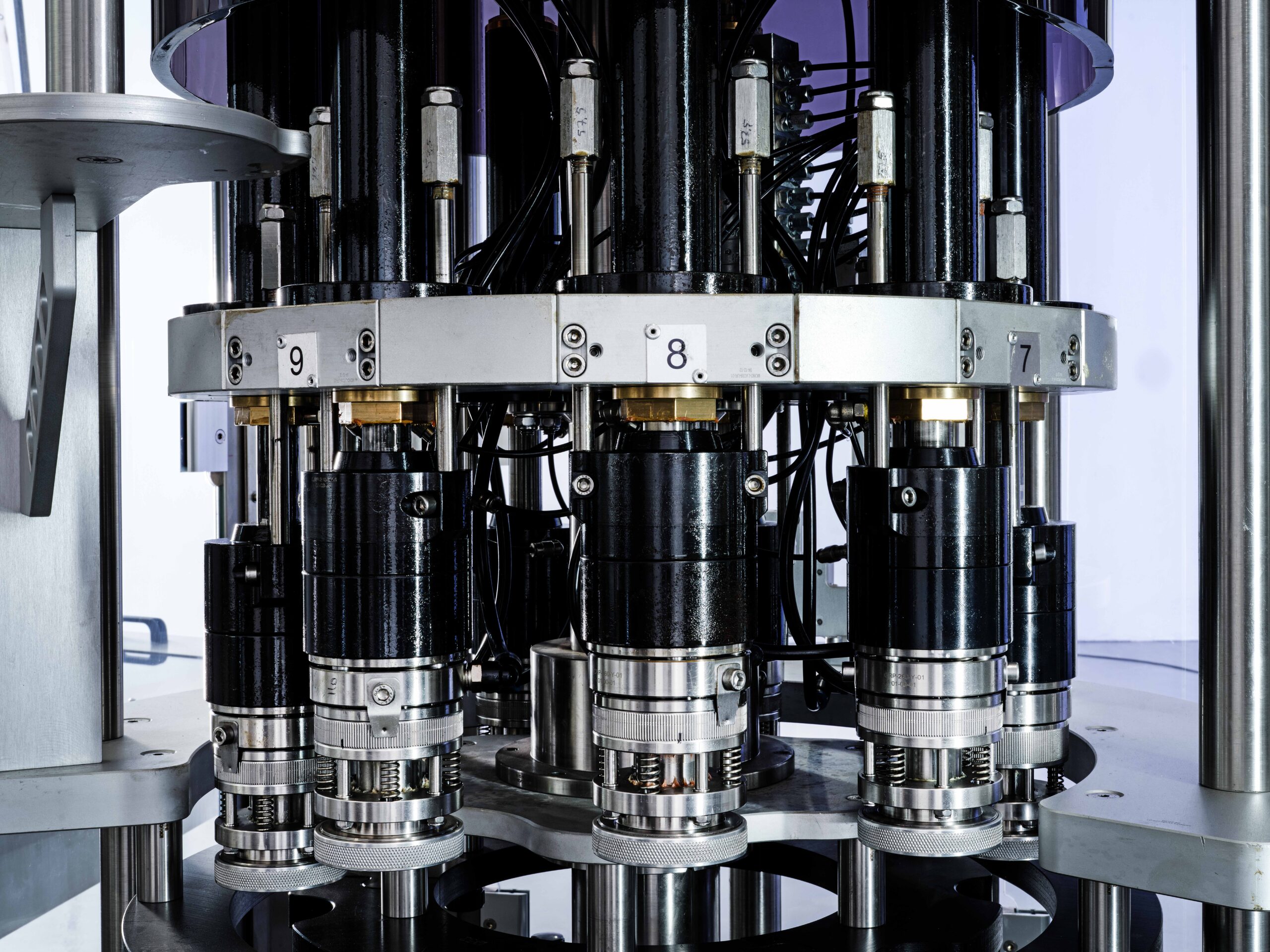

Thanks to their modular, multi-station design, our machines can perform multiple operations in a single pass—filling, capping, leak testing, labeling, and more. This setup allows for thousands of units per hour while significantly reducing labor needs and downtime.

With B.O.V technology, the product never comes into contact with the propellant gas. The internal bag keeps the product fresh without additives, extending shelf life. It’s particularly valuable for medical, cosmetic, and food products where hygiene is critical. Plus, it works with eco-friendly propellants, supporting sustainable manufacturing goals.

Our palletizing systems connect easily to the output of filling lines. They automatically arrange, wrap, and palletize products—eliminating manual handling, speeding up pre-shipment prep, and improving workplace safety.

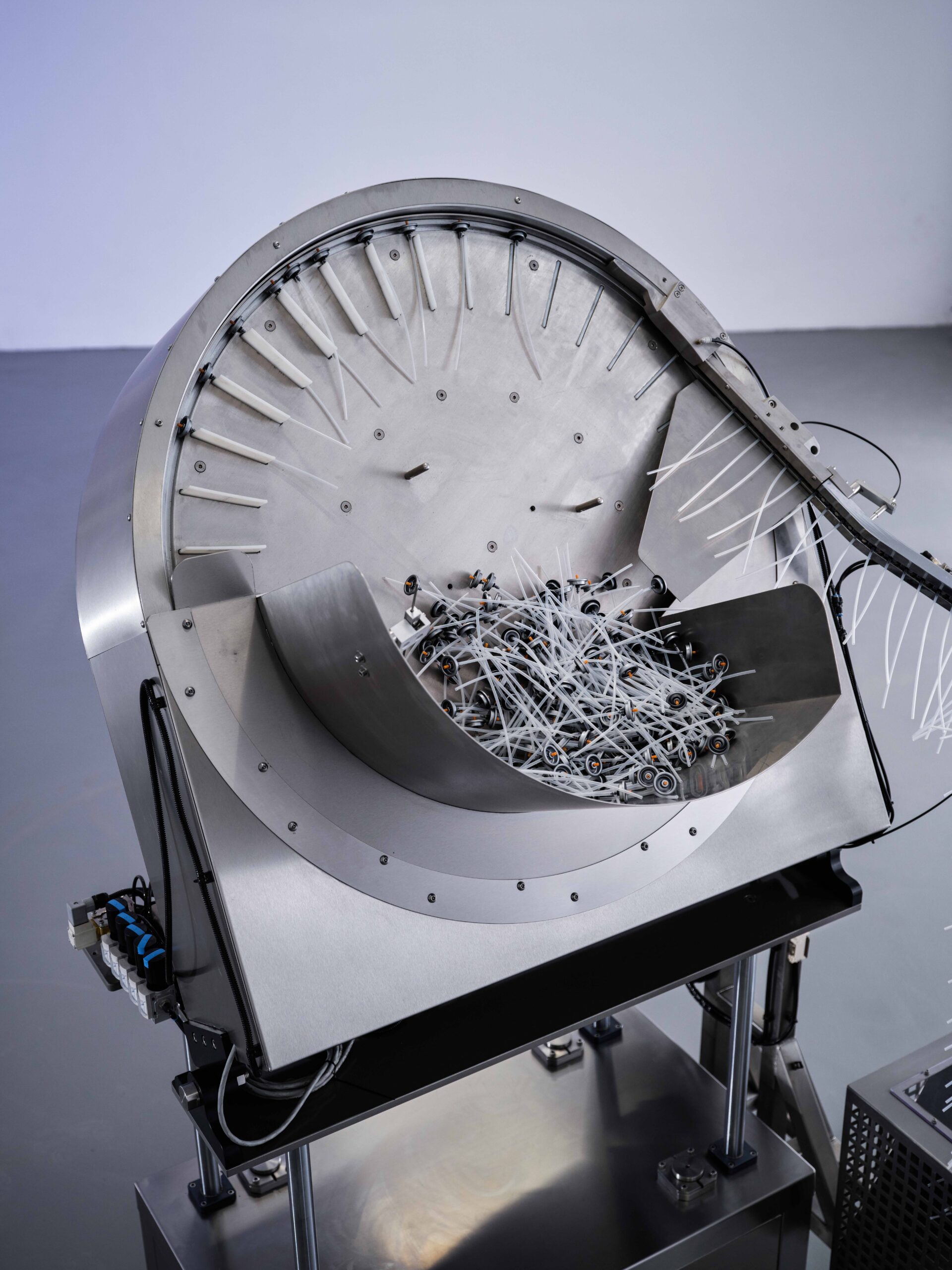

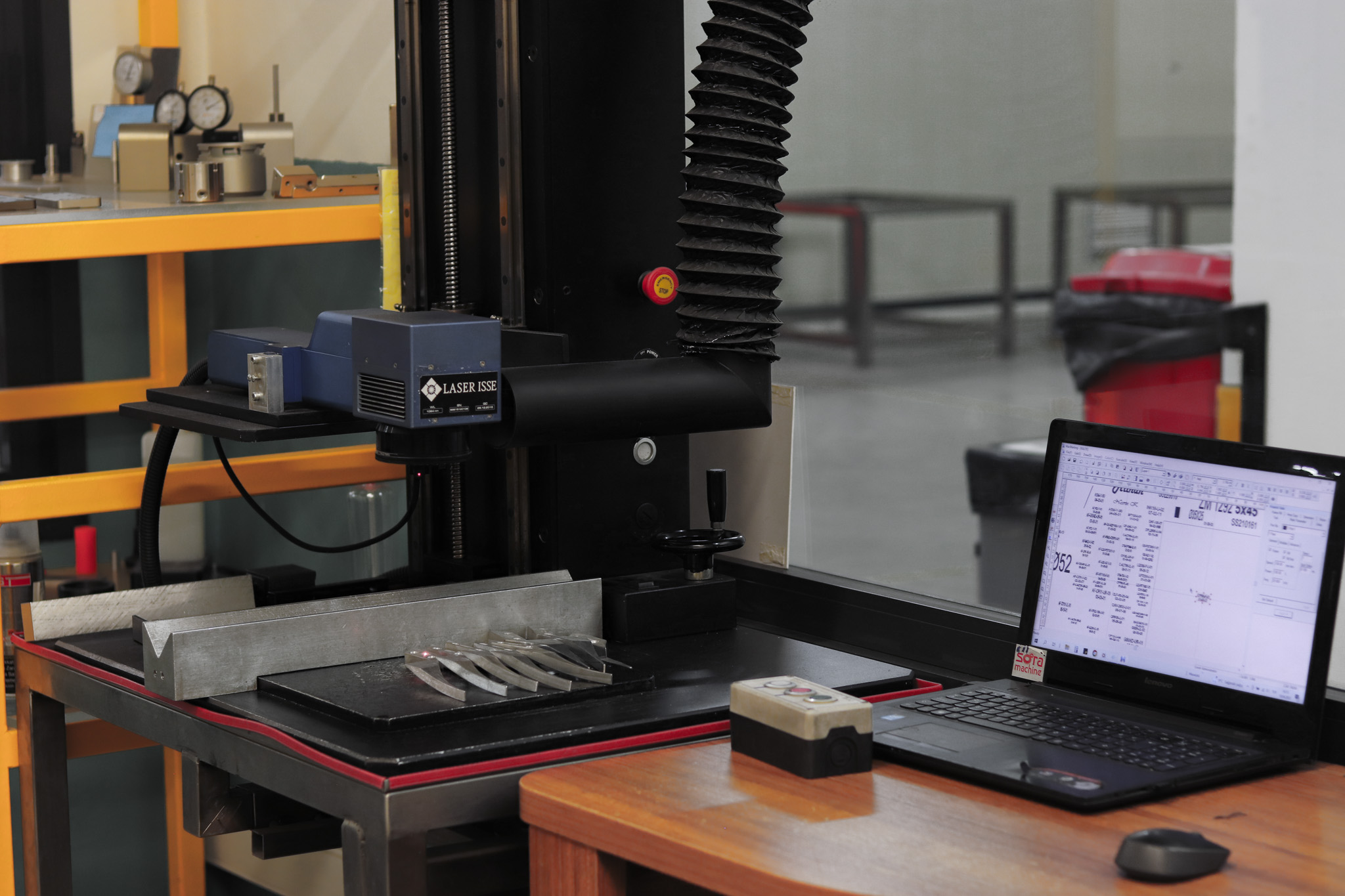

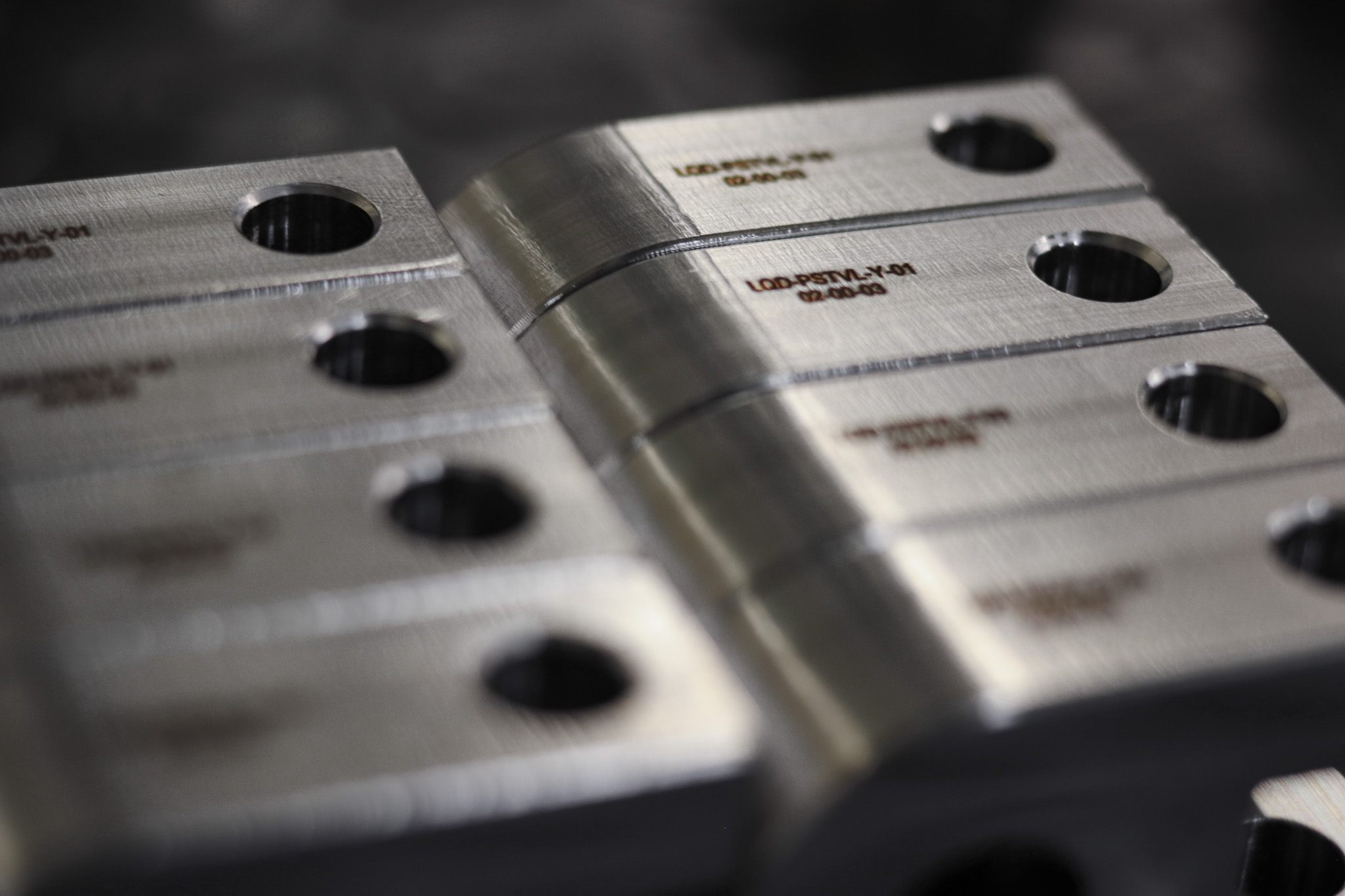

Before moving to full-scale production, trial runs are essential. Our lab-scale machines allow R&D teams to test new formulas and adjust production parameters. This helps catch potential issues early and accelerates product development.

Our automated testing stations check each product’s pressure resistance and leak-tightness within milliseconds. Any defective units are removed instantly, speeding up quality control and ensuring reliability.

Thanks to modular designs and quick-change parts, product switches are fast and straightforward. Using the touch-screen control panel, operators can adjust for different container sizes or packaging types in minutes—saving valuable time on multi-product lines.

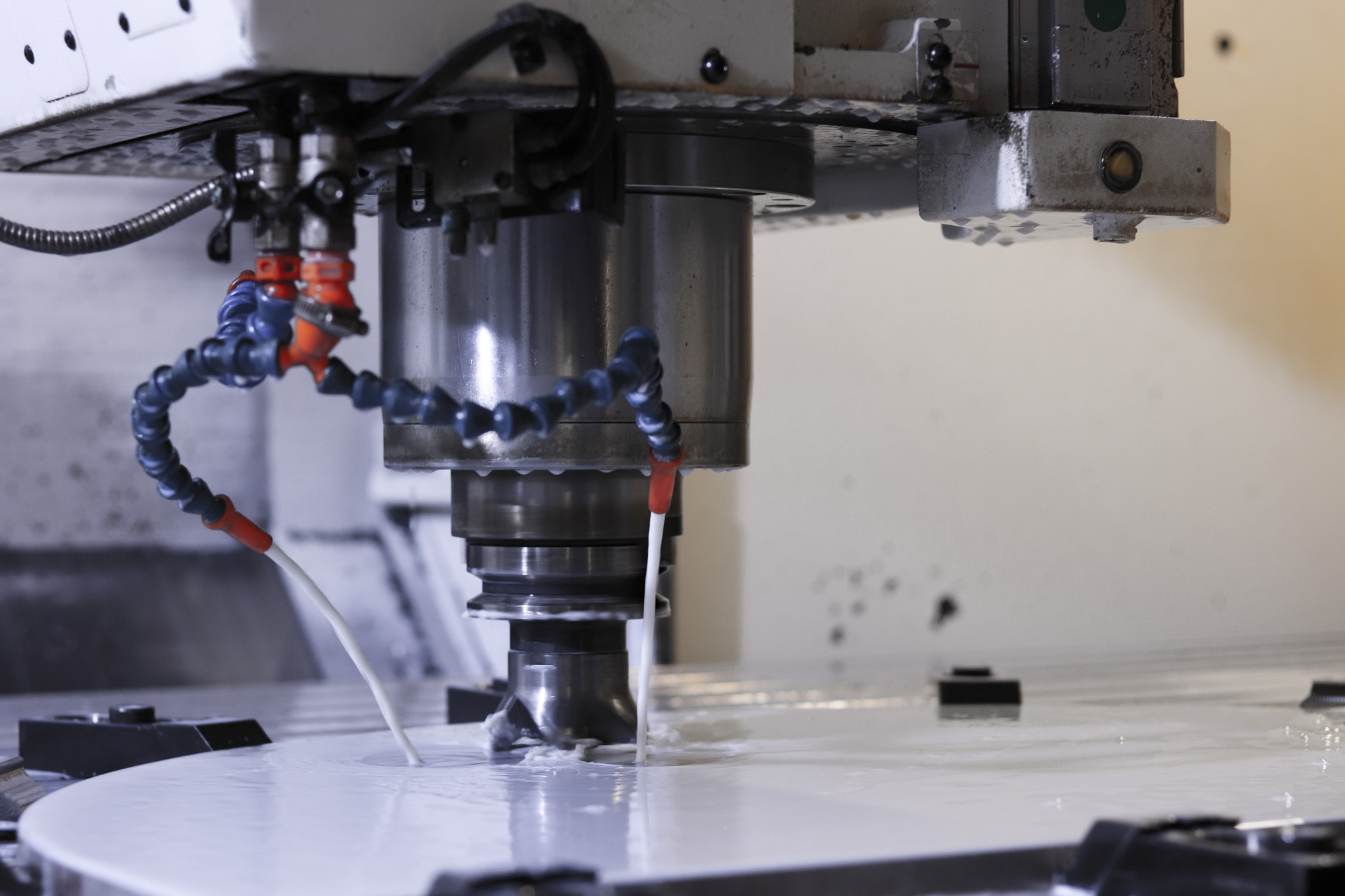

Sora Machine doesn’t just build machines—we manage the entire process from concept to commissioning. Design, manufacturing, installation, operator training, and technical support are all provided in one package, so you work with a single trusted partner.

We design specialized solutions for cosmetics, pharmaceuticals, cleaning products, food, automotive, and industrial maintenance. Each sector’s safety and packaging standards are carefully integrated into our technology.

By using servo motors, smart control software, and optimized air consumption, our machines consume less energy. This reduces both operating costs and carbon footprint, delivering eco-friendly, cost-saving production over the long term.