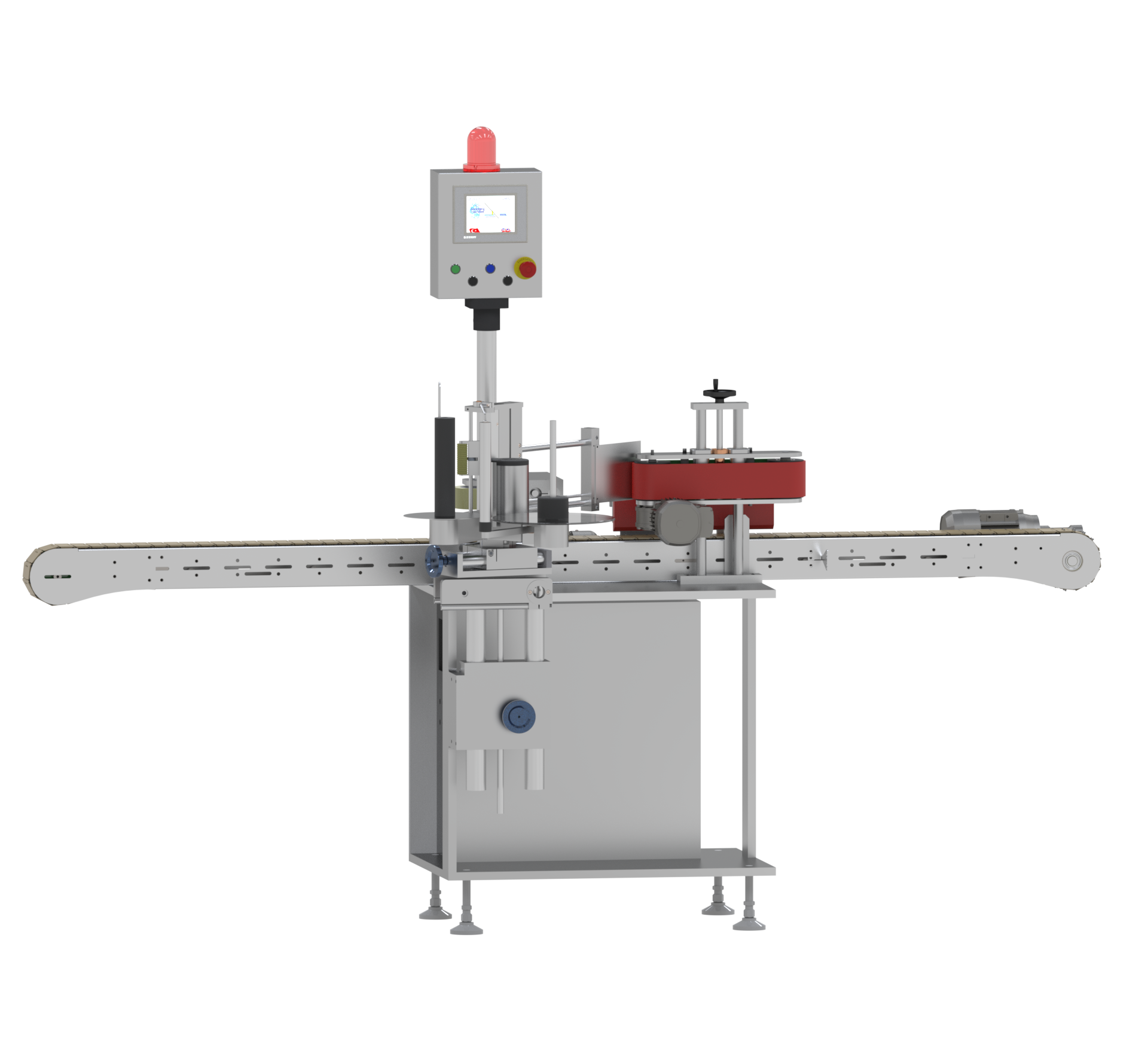

LABELING MACHINE

The LABELING MACHINE is a specialized, high-performance industrial system engineered for automated container labeling, featuring a double sided label module. Operational command is executed via a sophisticated Micro processor, ensuring precise execution of labeling parameters. The conveyor speed is finely regulated through PLC control working in concert with speed control by invertor. Constructed from hygienic and durable AISI 304 stainless steel, the machine manages efficient material flow with a role running system for empty label and provides crucial line monitoring via an alarm system for role breaking or end. Product handling is secured using a chain system for regulation of bottles.

Technical Advantages

- Dual-Application Capability: The machine utilizes a double sided label module, significantly enhancing throughput and versatility by applying two labels simultaneously or ensuring comprehensive container coverage.

- Integrated Digital Control: Features a core Micro processor command unit and separate PLC control for conveyor speed, allowing for precise synchronization with adjacent filling and packaging systems.

- Variable Speed Integration: Precision adjustments are managed via speed control by invertor, providing smooth acceleration/deceleration and optimizing alignment accuracy across different line speeds.

- Superior Material Integrity: Built entirely with AISI 304 stainless steel, meeting strict requirements for corrosion resistance and sanitation standards required in sensitive production environments.

- Optimized Container Handling: A dedicated chain system for regulation of bottles ensures containers remain stable and accurately positioned throughout the labeling process, minimizing application errors.

- Proactive Material Monitoring: Includes an alarm system for role breaking or end, immediately alerting operators to material issues and drastically reducing downtime associated with undetected label roll failures.

Utilized Technologies

The system integrates several industrial control and motion technologies to ensure high reliability and application accuracy:

- Microprocessor Command Architecture: Forms the backbone of the control system, managing overall machine functions and processing critical operational data.

- Programmable Logic Controller (PLC): Utilized specifically for governing and controlling the conveyor speed, enabling robust communication and integration with the wider packaging line infrastructure.

- Variable Frequency Drive (VFD/Inverter): Implements speed control by invertor technology to precisely modulate motor speeds, resulting in highly repeatable label placement and reduced mechanical stress.

- Stainless Steel Engineering (AISI 304): The selection of AISI 304 is a material technology choice that ensures compliance with hygiene regulations and offers long-term resistance to typical industrial cleaning agents and product exposure.

- Sensor and Monitoring Technology: Integrated sensors manage the role running system for empty label and trigger the crucial alarm system for role breaking or end, facilitating automation oversight.

Industrial Applications

This labeling solution is strategically designed to serve high-volume packaging manufacturers across multiple sensitive sectors (based on the manufacturer’s target industries):

- Cosmetics and Personal Care: Ideal for accurately applying front and back labels to bottles containing lotions, shampoos, and other personal care items.

- Liquid Filling Operations: Essential as the final step in fluid packaging lines, ensuring product identity and regulatory compliance.

- Pharmaceutical and Health: The AISI 304 construction makes it suitable for cleanroom or regulated environments requiring sanitary equipment standards.

- Turnkey Packaging Solutions: Serves as a modular unit ready for integration into complete industrial packaging setups, complementing other equipment like filling and pump tightening machines.

Operational Benefits

- Enhanced Production Output: The combination of precise speed control (invertor and PLC) and the double sided label module ensures the machine meets high-speed production targets while maintaining application quality.

- Reduced Product Rejection Rates: The rigid chain system for regulation of bottles guarantees optimal container stability, resulting in consistently accurate label positioning and minimizing product waste due to misalignment.

- Maximized Throughput Reliability: The automated alarm system for role breaking or end provides real-time failure detection, allowing operators to intervene instantly and preventing prolonged line stops.

- Simplified Integration and Control: The use of Micro processor and PLC control simplifies interfacing with master facility management systems and provides operators with centralized speed and operational command.

- Long-Term Asset Value: The robust AISI 304 construction guarantees machine longevity and resistance to degradation in harsh operating environments, ensuring a strong return on investment.