LEAK DETECTION DEVICE

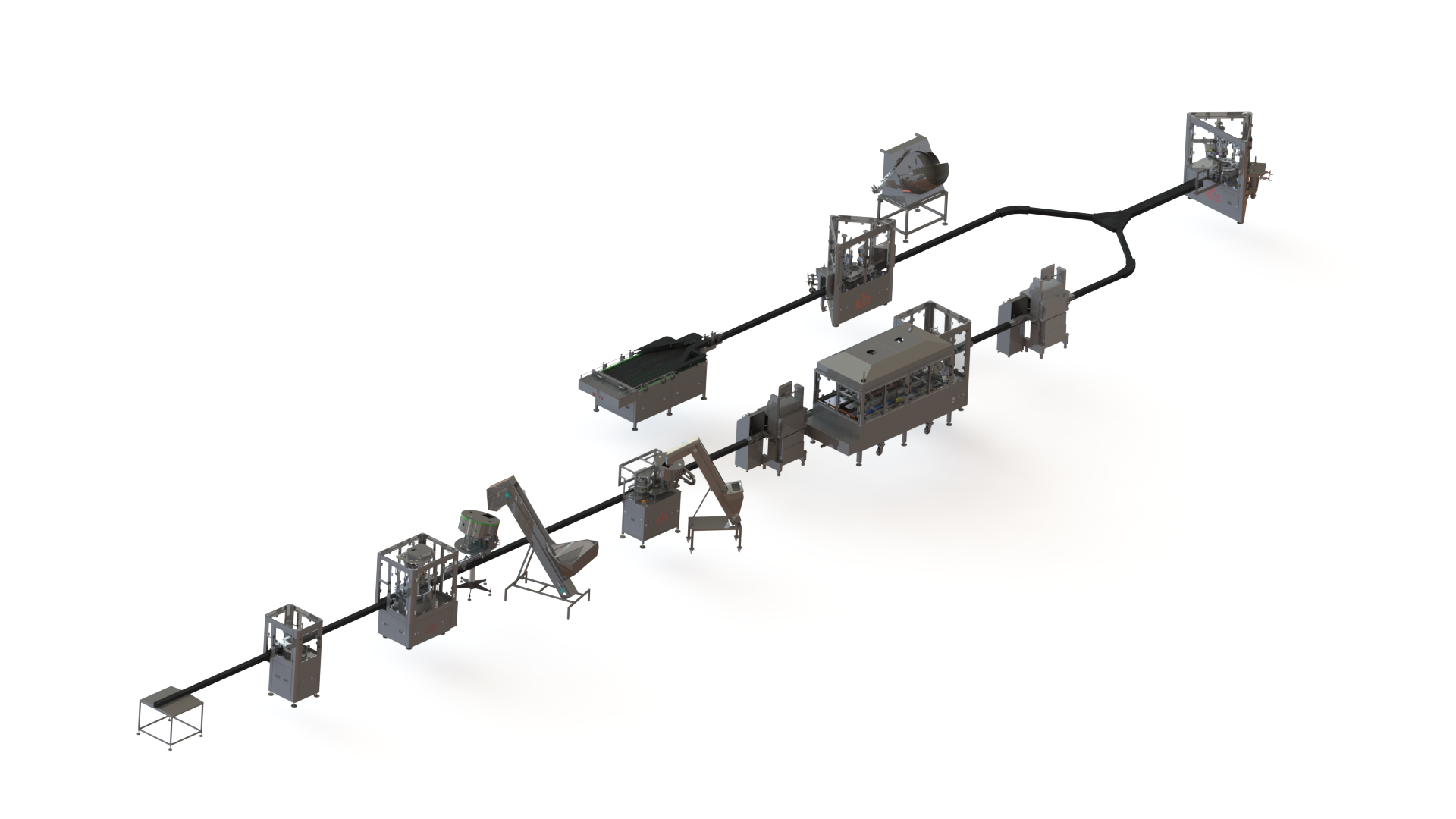

Leak Detection Device is a specialized, high-performance quality control solution essential for ensuring container integrity in high-speed industrial filling lines, particularly within the aerosol sector. Engineered for demanding production schedules, the system is capable of inspecting up to 150 cans per minute and operates with standard remote connection and data recording/logging capabilities to ensure traceability and streamlined monitoring. Crucially, the device holds ATEX Zone II certification, guaranteeing safe and compliant operation in hazardous production environments. It offers versatile can handling and superior sensitivity, establishing it as a reliable component for critical quality assurance.

Technical Advantages

- High Throughput Capability: Processes production lines at speeds of Up to 150 Cans Per Minute (CPM), maintaining high productivity without sacrificing quality control.

- Superior Leak Sensitivity: Provides standard micro leak detection at 8 x 10⁻³ mbarls⁻¹ and an alternative, high-precision leak detection mode down to 2 x 10⁻³ mbarls⁻¹.

- Hazardous Area Compliance: Certified for safe use in explosive atmospheres, meeting the stringent requirements of ATEX Zone II.

- Versatile Container Handling: Accommodates a broad range of can dimensions, specifically Up to 80mm Diameter and 400mm High.

- Integrated Data Management: Features Data Recording/Logging and Remote Connection available as standard, facilitating advanced diagnostics and process optimization.

- Compact Footprint: Requires minimal floor space, needing only 1.0m for straight track integration.

Used Technologies (System Architecture and Detection Methodologies)

The device utilizes sophisticated, high-precision detection methodologies coupled with industrial control interfaces:

- Precision Micro Leak Detection Methodology: The system covers both Standard Micro Leak and high-sensitivity Alternative Leak thresholds, offering a quantitative measure of container integrity. The sensitivity specifications are precise enough to cover traditional methods like the Water bath alternative, while providing advanced dry testing capabilities.

- Industrial Control Interface (HMI): Management and operation are controlled via a Wall Mountable VESA HMI, with input/output signals driven by 24V DC for robust industrial control.

- Automated Rejection System: The system includes a Reject bin mechanism to automatically divert non-compliant or leaking cans from the production stream, maintaining line efficiency.

- Pneumatic and Electrical Requirements: Requires a supply of 4 Bar, Dry & Oil Free compressed air, and operates the main system on 24V DC, with a dedicated 110V / 220V AC Sampling Blower.

Industrial Applications

The Leak Detection Device is an essential component within various high-volume filling and packaging operations, especially where product integrity and safety compliance are critical:

- Aerosol Filling Lines: It is specifically engineered to integrate into complete aerosol production lines, complementing components such as propellant filling machines and checkweighers.

- Pharmaceutical Packaging: Used in processes requiring maximum security against micro-leaks in sealed containers.

- Cosmetics Industry: Applicable for quality assurance in pressurized or sensitive cosmetic product packaging.

- Industrial Liquid Filling: Utilized in general liquid filling processes requiring sealed container integrity.

Operational Benefits

Targeted at engineers, procurement professionals, and factory managers, the operational benefits deliver measurable improvements in quality, safety, and efficiency:

- Enhanced Safety and Regulatory Assurance: ATEX Zone II compliance ensures the equipment meets stringent safety standards for flammable material handling areas, protecting personnel and assets.

- Maximized Quality Control: The exceptional sensitivity detects even minute defects, significantly reducing product recalls and improving brand integrity.

- Reduced Total Cost of Ownership (TCO): Standard features like Remote Connection and Data Logging reduce diagnostic time and simplify remote maintenance and troubleshooting.

- Seamless Integration: The compact 1.0m track requirement and industry-standard 24V DC I/O signals allow for easy installation into new or existing high-speed production lines.

- Automated Quality Loop: The integrated reject bin mechanism ensures automatic and reliable removal of failed products, minimizing manual intervention and bottlenecks.

Technical Specification

- Line Speed : Up to 150 Cans Per Minute

- Can Dimensions : Up to 80mm Diameter, 400mm High

- Sensitivity : Covers Both Standard Micro Leak : 8 x 10 -3 mbarls-1 And Water bath

- Alternative Leak : 2 x 10-3 mbarls-1

- HMI : Wall Mountable VESA HMI Floor Mountable Stand Optional

- User Interface : 24V DC Input/Output Signals

- Remote Connection : Available as standard

- Data Recording/ Logging : Available as standard

- Line Space : 1.0m for straight track

- Compressed Air Supply : 4 Bar, Dry & Oil Free

- Operating Voltage System : 24V DC 5A Sampling Blower : 110V /220V AC, 3A

- Operating Temperature : 10 to 40°C

- Hazardous Area : ATEX Zone II

- Reject bin to accommodate rejected cans