What Is a Collecting Table and Why Is It Essential in Liquid Filling Lines?

A collecting table is the final station in a liquid filling line where finished products are accumulated after filling, capping, or labeling. Also known as an accumulation table, it serves as a buffer zone that collects filled bottles or containers, allowing operators to package them without interrupting the flow of the production line.

In systems with up to 60 BPM (bottles per minute) capacity, a collecting table prevents line congestion, supports smoother workflow, and enhances overall production efficiency—especially in semi-automated or operator-assisted environments.

How Does a Collecting Table Work?

A collecting table operates through a rotating or fixed flat surface positioned at the end of the production conveyor. As filled bottles exit the line:

-

Products arrive on the conveyor belt

-

They are gently guided onto the collecting table surface

-

Operators manually remove or pack the bottles as they accumulate

The rotating models ensure even distribution of products on the table surface. Collecting tables typically work without active sensors or motors, making them mechanically simple but operationally crucial.

What Are the Benefits of Using a Collecting Table in Semi-Automated Filling Systems?

In production environments such as Liq-mak up to 60 bpm, the collection of tables offers significant operational advantages::

-

Improved efficiency: Operators can handle packaging in parallel without slowing down the line

-

Reduced bottlenecks: Prevents line stoppages due to full conveyors

-

Labor optimization: Operators focus on packing instead of chasing bottles on the line

-

Smooth product flow: Ideal for lines with intermittent downstream activity

-

Flexible use: Can be used in various industries like cosmetics, pharmaceuticals, or food

Especially in compact production setups, collecting tables increase flexibility without requiring advanced automation.

Where Is a Collecting Table Typically Placed in a Liquid Filling Line?

The collecting table is positioned at the end of the conveyor line, directly following the last machine in the process (usually the capping or labeling unit). Its primary function is to:

-

Gather finished products before secondary packaging

-

Offer buffer time to downstream operators

-

Allow for inspection or batch sorting if necessary

It can also be placed between stages as a temporary holding area, especially when one part of the system is faster than the next.

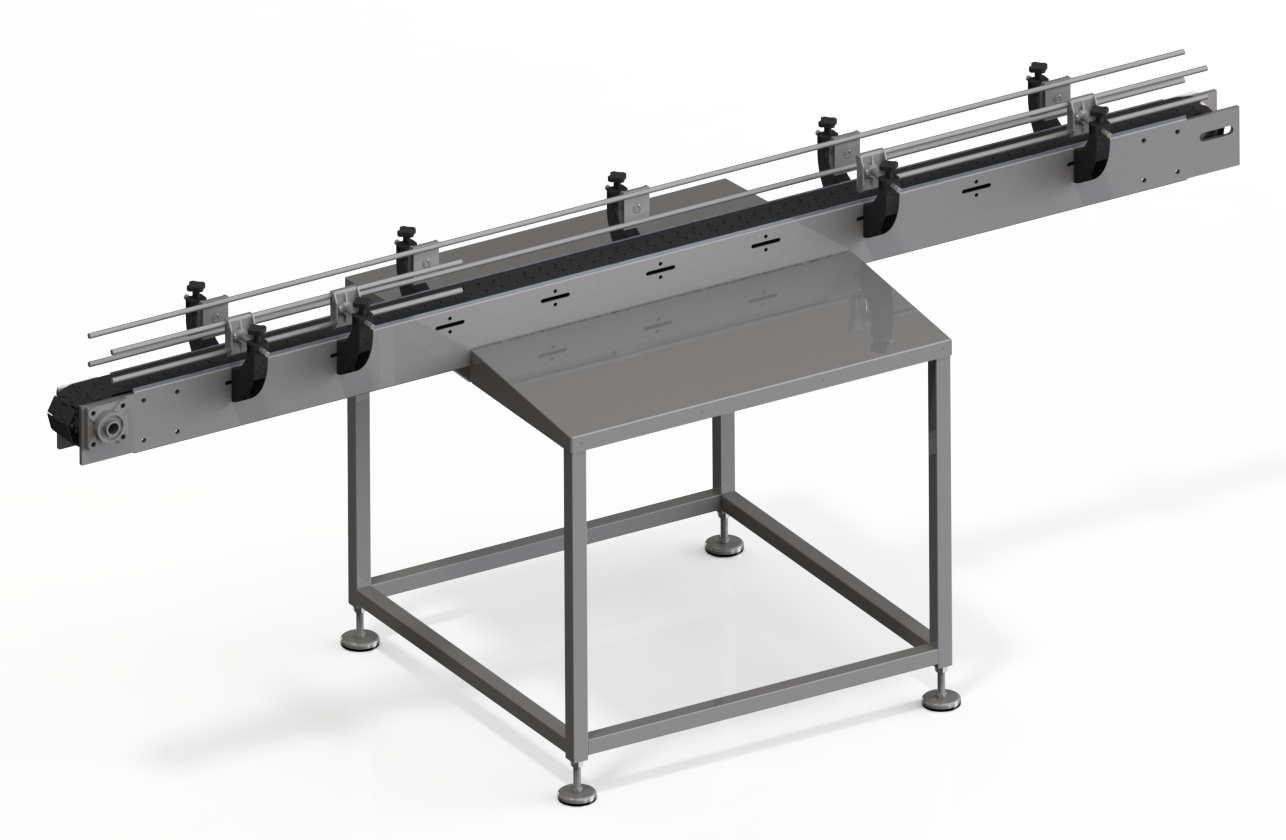

What Are the Key Features of Sora Machine’s Collecting Tables?

Sora Machine’s collecting tables are designed for durability, hygiene, and ergonomic use. Key technical specifications and features include:

-

Stainless steel construction for easy cleaning and corrosion resistance

-

Height-adjustable legs for seamless integration with different line heights

-

Polished flat or rotating tabletop (optional) for smooth bottle movement

-

Safety edges and non-slip feet for secure operation

-

Customizable dimensions based on container size and line layout

These tables are manufactured to suit a wide range of packaging formats, including PET, glass, and plastic bottles in various shapes and volumes.

In Which Industries Are Collecting Tables Commonly Used?

Collecting tables are standard equipment across multiple low-to-medium speed filling applications. Most common sectors include:

-

Cosmetics – Liquid foundation, toner, micellar water, serums

-

Pharmaceuticals – Syrups, oral solutions, tinctures

-

Personal Care – Shampoos, lotions, body wash

-

Household Chemicals – Cleaning liquids, surface sprays

-

Food & Beverage – Condiments, sauces, flavored syrups

Any product that is packaged in bottles or containers and requires operator handling at the end of the line can benefit from a collecting table.

What Should You Consider When Choosing a Collecting Table?

Before selecting a collecting table, manufacturers should evaluate several factors:

-

Line speed: Is the BPM compatible with the table size and surface area?

-

Container type and stability: Will the bottles remain upright and balanced?

-

Available floor space: Can the table fit at the end of the line without obstructing flow?

-

Operator access: Is the layout ergonomic for packing and quality checks?

-

Surface type: Do you need a rotating disk or a flat accumulation zone?

Sora Machine helps clients choose or customize the ideal collecting table for their specific line configuration.

Can a Collecting Table Be Upgraded or Automated?

Yes, collecting tables can be upgraded with additional features or adapted for higher efficiency. Some possible enhancements include:

-

Rotating turntables to keep product flow continuous

-

Sensor-based accumulation control to prevent overflow

-

Integration with downstream packing equipment

-

Mobility wheels or locking casters for repositioning

-

Adjustable guides for multi-format bottles

While the base version is manual and mechanical, semi-automation is possible with minimal investment.