What is a Labeling Machine and Why is it Important?

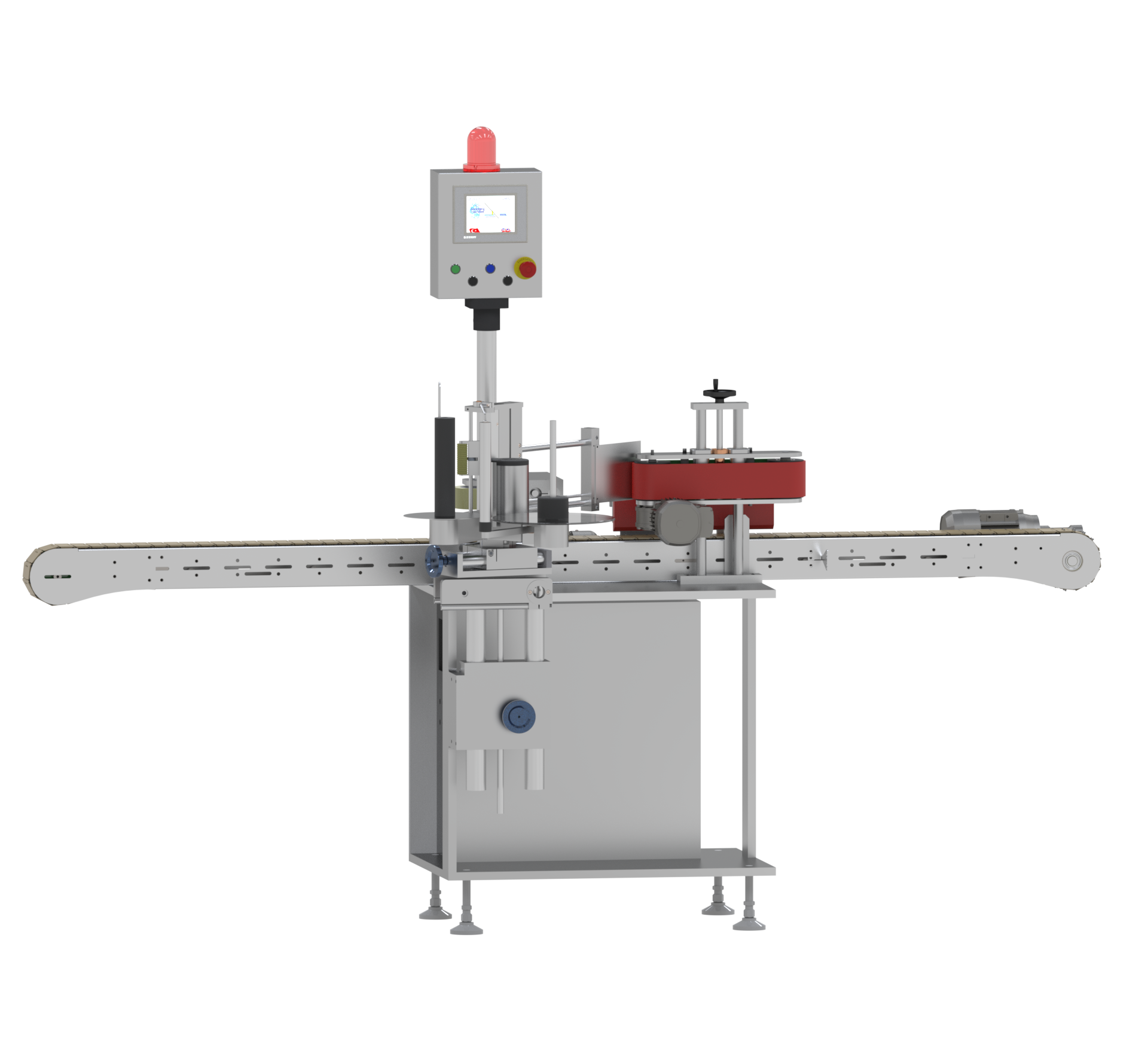

Labeling machines are critical equipment at the final stage of a liquid filling line, essential for clarifying product identity and ensuring brand consistency. Sora Machine’s LIQ-MAK UP TO 60 BPM stands out as an indispensable component of modern production lines, offering high speed, precision, and a flexible design.

What Product Types Is It Used For?

This labeling system is developed to work seamlessly with liquid filling machines and can be used for packaging products such as:

- Cosmetics like shampoo, body lotion, and hair conditioner

- Disinfectants, liquid soaps, and cleaning products

- Liquid sauces, oils, and beverages used in the food industry

- Pharmaceutical products and specially formulated liquid products

The machine is compatible with plastic and glass bottles of various diameters and heights.

What Features Make the LIQ-MAK 60 BPM Labeling Machine Stand Out?

1. High Capacity

This model boasts a labeling capacity of up to 60 bottles per minute. It integrates smoothly into fast-paced production processes, preventing bottlenecks.

2. Adjustable Structure

The machine is adjustable to accommodate different bottle diameters and label sizes. This flexibility allows for the management of a wide range of product groups through a single system.

3. PLC-Controlled Automation

The fully automatic control system is combined with a user-friendly touchscreen interface. Operators can easily manage parameters such as:

- Label length

- Application position

- Bottle counter

What Are the Technical Details?

How is it Positioned in the Production Line?

The labeling machine is integrated at the end of the filling line. When used in conjunction with the following systems, it ensures a complete production flow:

- Automatic Bottle Feeder

- Vacuum or piston filling machines

- Capping and tightening units

- Sleeve dropping machines

- Collecting table

This integration allows bottles to complete all stages, from filling to labeling, without interruption.

Does It Offer Operational Ease?

Yes. The system can be easily managed by a single operator. Features that enhance user experience include:

- Quick transitions during format changes

- Plug-and-play installation

- Tool-free mechanical adjustments

- Live monitoring via screen for fault detection and error alerts