What is a Pump Sorting and Fitting Machine and What Does It Do?

A Pump Sorting and Fitting Machine is an automated system designed to automatically sort, orient, and assemble pump caps onto bottles in liquid filling lines. It optimizes production processes, especially in the cosmetics, personal care, pharmaceutical, and cleaning product industries, by performing pump placement with high speed and precision.

In Which Production Lines Is This Machine Used?

Pump sorting and fitting machines are an essential part of automatic liquid filling lines. They are typically used in the following lines:

- Filling lines for personal care products like shampoo, soap, and lotion.

- Cosmetic product lines such as perfume, cologne, and body mist.

- Chemical product lines for items like disinfectants and surface cleaners.

- Liquid product packaging lines in the food industry (e.g., sauces, liquid sweeteners).

These systems are compatible with both plastic and metal pumps, offering flexible and modular production capabilities.

How Does an Automatic Pump Sorting System Work?

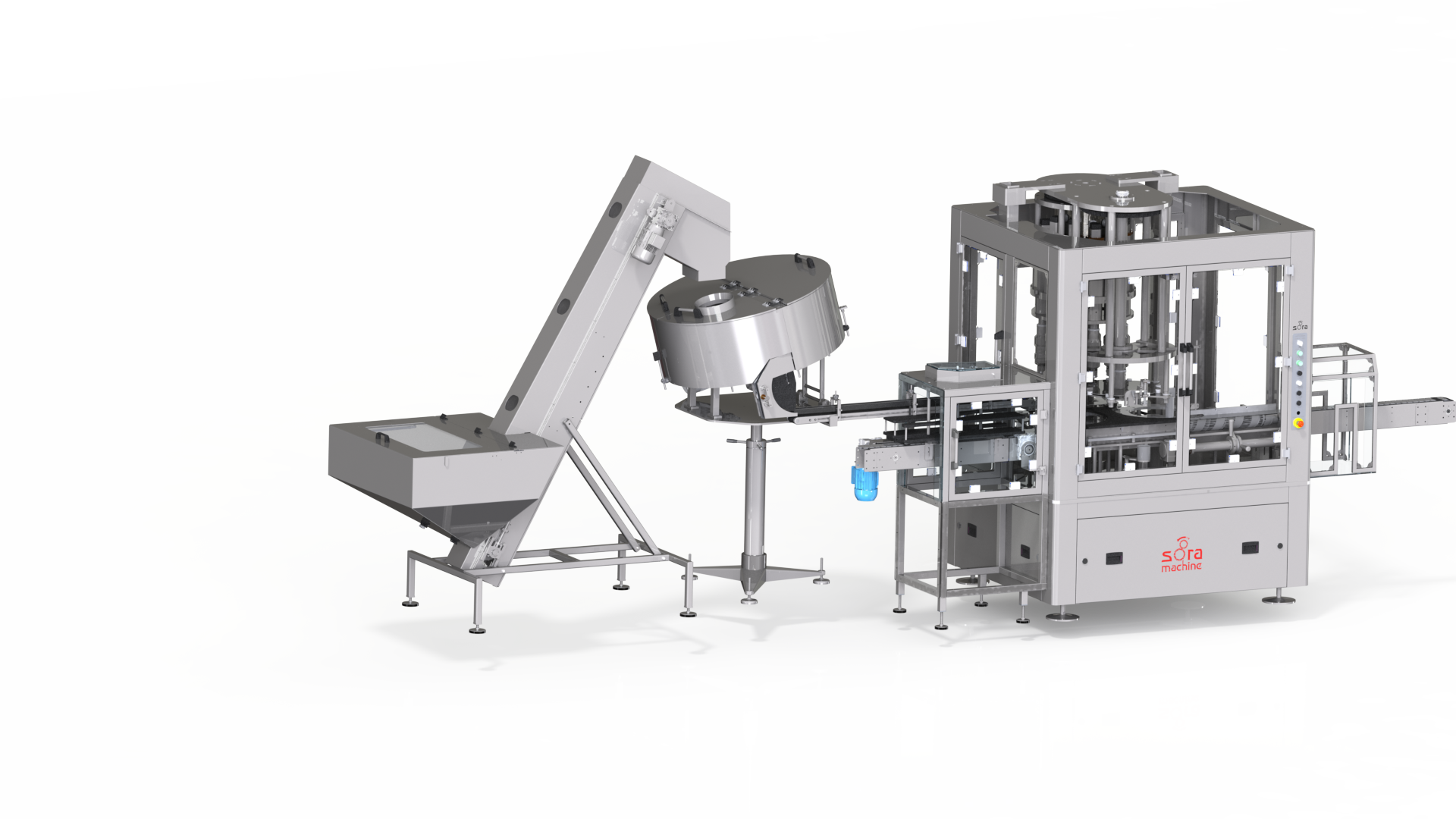

The pump fitting machine developed by Sora Machine operates as follows:

- Pump Feeding Unit: Bulk pumps are organized by a vibratory system.

- Pump Sorting Mechanism: Pump nozzles and tubes are sorted by proper orientation.

- Positioning and Transfer: Properly sorted pumps are transferred to conveyor belts.

- Pump Placement Head: The pump is placed onto the bottle, with its accuracy checked.

- Torque-Controlled Tightening (optional): If the pump is screw-on, a torque-controlled tightening unit is activated.

This system can be customized for both dispenser pumps and spray pumps.

How Does the Machine Increase Production Efficiency?

The advantages offered by this automatic pump fitting system include:

- Minimizing human error.

- Reducing processing time per bottle.

- Ensuring more consistent and aligned placement.

- Lowering waste rates through operational speed.

- Decreasing labor costs in the long run.

Thanks to automation, production line downtime is avoided, and the Return on Investment (ROI) period is shortened.

With Which Other Systems Can This Machine Integrate?

The Pump Sorting and Fitting Machine can seamlessly integrate with Sora Machine’s LIQ MAK Up to 60 BPM liquid filling line. This creates a fully automatic line, ensuring uninterrupted and error-free production.

Why is Sora Machine Preferred in This Field?

Sora Machine is not just a machine manufacturer; it’s also a system partner that provides turnkey solutions to manufacturers. The key advantages it offers with this product include:

- Flexible production: Quick transition between different pump types.

- Compact design: Saves space.

- Fast maintenance and cleaning: Contact surfaces can be easily sterilized.

- Remote support systems: Error diagnosis and solutions via PLC.

Furthermore, Sora’s service and technical support team assists users with post-installation training and maintenance processes.