What is a Pump Tightening and in Which Production Processes is It Used?

A Pump Tightening is an automatic capping station specifically designed to securely screw on pump caps in liquid filling lines. For pump bottles containing liquid soap, shampoo, disinfectants, cleaning products, and similar items, it’s crucial not only to place the cap but also to tighten it with a specific torque. Therefore, this unit was developed to ensure consistency, safety, and efficiency in the production line.

What Types of Caps Are Compatible with This System?

Sora Machine’s Pump Tightening unit is compatible with the following cap types:

- Pump caps

- Trigger spray caps

- Disc top or flip top caps (compatible versions)

- Screw-type liquid dosing pumps

The machine can be customized to accommodate different sized caps, as it’s equipped with adjustable mechanical and pneumatic systems based on the cap’s geometry. Its flexible design allows for working with various packaging types on a single line.

How Does the Pump Tightening Unit Increase Production Efficiency?

Manual tightening processes can lead to both time loss and inconsistent product quality due to uneven torque. The Pump Tightening unit helps achieve:

- Guaranteed sealing by applying equal torque to every bottle.

- Reduced operator intervention and improved ergonomics.

- Optimized overall production speed by shortening the tightening time.

Additionally, because the error rate is minimized, there is a lower rejection rate during the final product quality control stage.

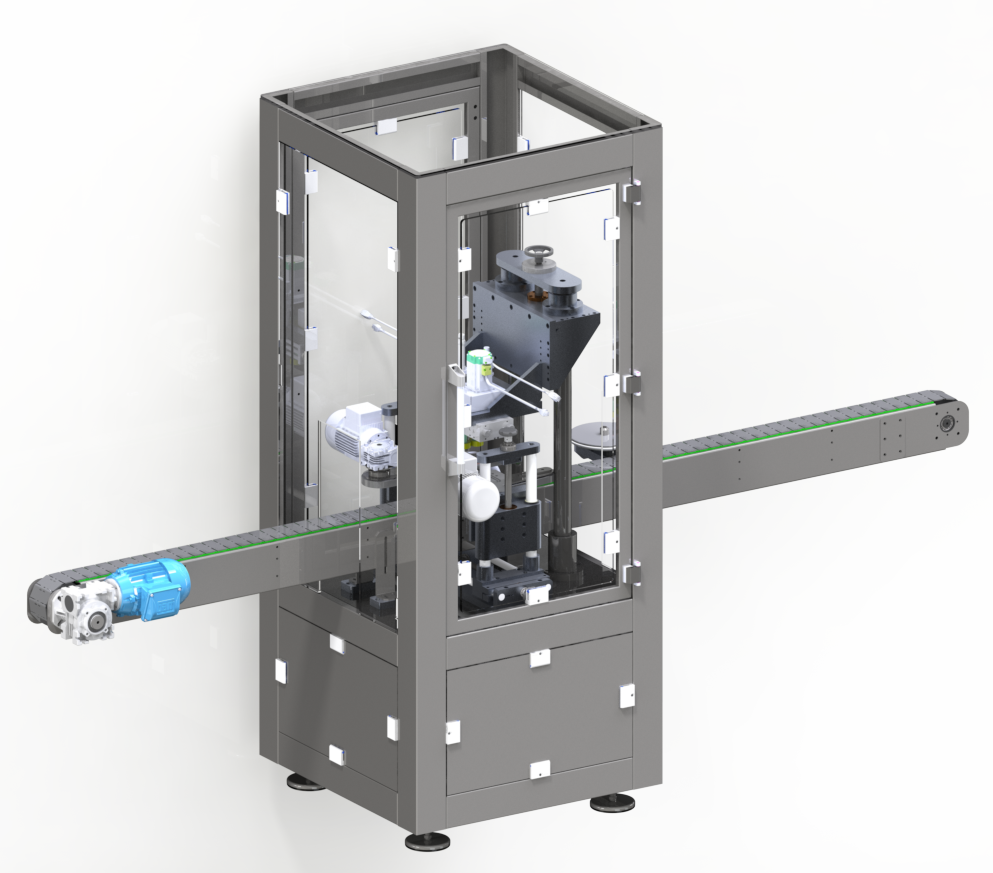

What is Its Technical Structure and Ease of Integration?

Sora Machine’s unit features a modular design, making it easy to integrate into existing filling lines. Some of its technical features include:

- Automatic or semi-automatic torque adjustment

- High-precision tightening heads

- Pneumatic or servo motor-assisted system

- Structure suitable for continuous pass-through production on a conveyor

All these features ensure uninterrupted production by performing the tightening operation without stopping the line.

Which Industries Should Prefer This System?

The Pump Tightening unit can be used in almost any industry that produces liquid, semi-liquid, or viscous products:

- Cosmetics industry: Shampoo, conditioner, lotion, hand soap

- Medical products: Disinfectants, antiseptics

- Household cleaning products: Surface cleaners, liquid detergents

- Food industry: Syrups, sauces, liquid supplements (in pump packaging)

Thanks to its wide range of applications, this system is suitable for both small-scale manufacturers and high-capacity facilities.

How to Get the Highest Performance from the Tightening Unit?

To increase efficiency, it’s recommended to pay attention to the following details:

- The tightening torque should be correctly calibrated according to the cap and product type used.

- It should be ensured to work in coordination with the cap placement unit on the line.

- Cleaning and maintenance periods for the tightening heads should be performed regularly during operation.

These measures will increase the system’s performance and minimize the breakdown rate.