What is the LIQ MAK Up to 60 BPM?

Sora Machine’s LIQ MAK Up to 60 BPM model is an automatic liquid filling machine engineered for high-speed and precise filling of liquid products. Reaching a maximum speed of 60 bottles per minute (BPM) on production lines, this system offers hygienic filling, repeatability, and a low defect rate. It’s particularly favored for liquid formulations in cosmetics, personal care, pharmaceuticals, and cleaning products.

Which Product Types is It Suitable For?

LIQ MAK is adaptable for filling a wide range of products with varying viscosities. It’s commonly used for:

- Toners and lotions

- Makeup removers

- Alcohol-based products like cologne and perfume

- Personal care items such as liquid soap, shampoo, and shower gel

- Medical antiseptics and disinfectants

- Household cleaning solutions

Its adaptability to different mouth diameters, cap types, and bottle shapes allows for the production of multiple product variations on a single line.

What Filling Technology Does This Machine Utilize?

The Sora Machine LIQ MAK model employs precise volumetric filling technology. This ensures that the same amount of product is filled into each bottle at a consistent speed and pressure. Key technological features of the filling system include:

- Adjustable filling volume

- Drip-free nozzles

- Top-to-bottom filling option to prevent foaming

- Anti-drip mechanism

These features prevent waste during filling, reduce cleaning needs, and enhance hygiene standards.

What Does “60 Bottles Per Minute” Really Mean?

A speed of 60 BPM (Bottles Per Minute) signifies an optimal level of productivity, especially for medium to large-scale production lines. This capacity:

- Helps meet high demand during promotional periods.

- Reduces production time, thereby lowering labor costs.

- Optimizes production costs by decreasing waste.

In essence, when integrated with proper bottle feeding and collection systems, it forms the core of a fully automated and highly efficient filling line.

How Does a Sleeve Dropping Machine Play a Role in This Process?

A Sleeve Dropping Machine, which can be integrated into the LIQ MAK line, automatically applies shrink sleeves (heat-shrinkable labels) to product packaging after bottle filling. This system:

- Precisely places transparent or pre-printed sleeves onto bottles.

- Eliminates alignment errors common with manual application.

- Works seamlessly at high speeds, without disrupting production flow.

- Integrates with systems like a shrink tunnel to ensure the label perfectly conforms to the product.

The Sleeve Dropping Machine is a critical component for enhancing visual integrity and brand perception, particularly in the cosmetics and personal care sectors.

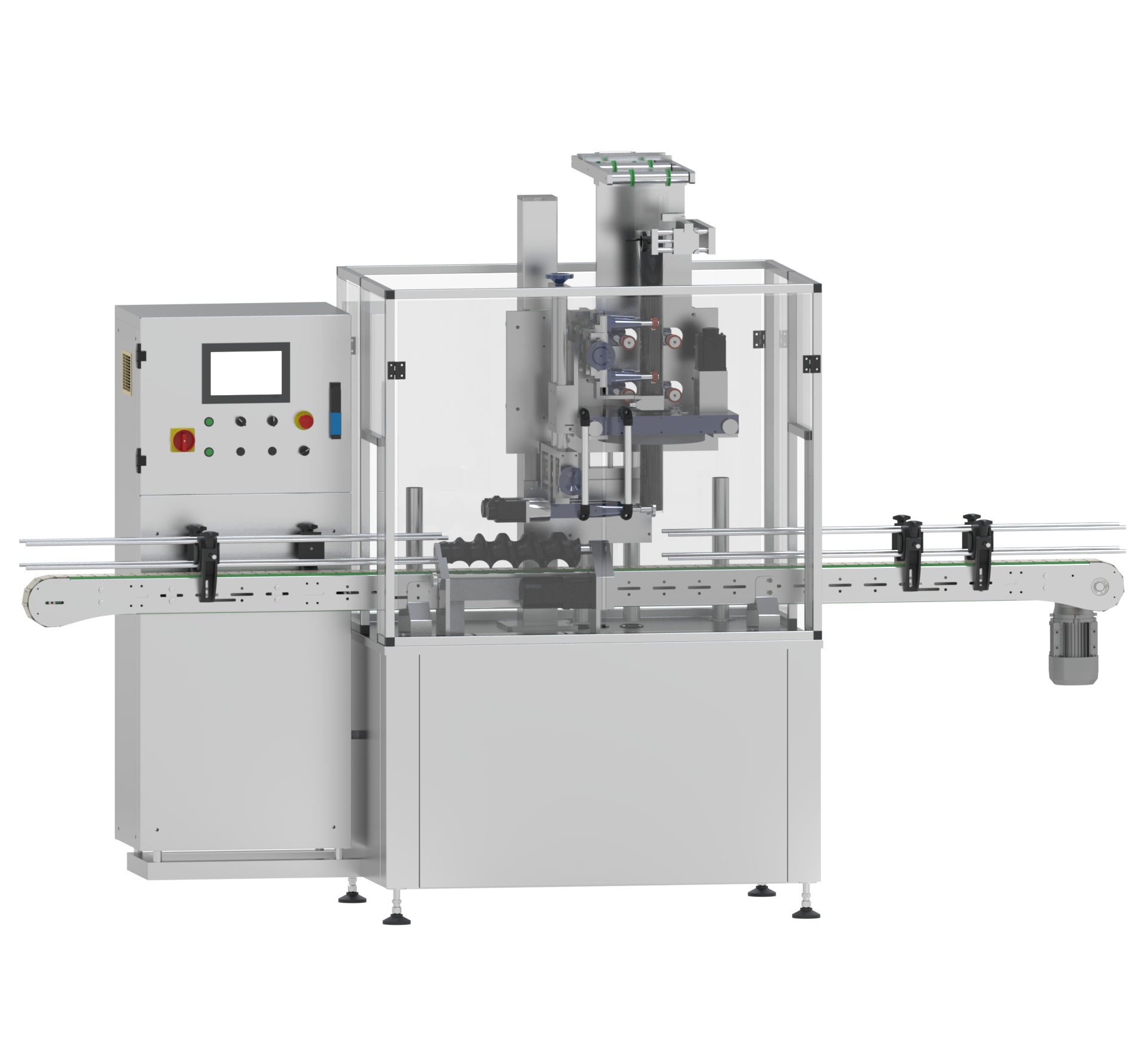

What Technical Features Make This Machine Stand Out?

The outstanding technical features of LIQ MAK include:

- 60 BPM production capacity

- Stainless steel body and GMP-compliant design

- Compatibility with automatic bottle feeding options

- Control via a PLC control panel and touchscreen display

- Modular structure allowing for quick format changes

- Integration infrastructure for capping and sleeve labeling systems

This design allows it to operate seamlessly in both fixed and modular production environments.

Which Sora Machine Units Can It Be Integrated With?

LIQ MAK can be integrated with other Sora Machine automation solutions to maximize production efficiency, including:

- Rotary Feeding Table: Ensures bottles are correctly fed into the machine.

- Rotary Collecting Table: Helps organize products emerging from the filling process.

- Monoblock Feeding Station: Can be used as a system that feeds the entire integrated process.

- Sleeve Dropping Machine: Ensures visual quality and product integrity during the labeling process.

What is the Level of Compliance with Hygiene Standards?

All surfaces of LIQ MAK are manufactured from AISI 304/316 quality stainless steel, designed in compliance with GMP and HACCP requirements. Additionally, it features:

- Easily accessible covers and nozzles for cleaning.

- Leak-proof sealing systems at liquid transfer points.

- A washable, sterilization-compatible structure.

This design enables the safe execution of processes involving hygiene risks, particularly for medical and personal care products.

Why Should You Choose LIQ MAK?

Sora Machine’s LIQ MAK model stands out with its combination of high-precision filling, modular design, hygienic construction, and speed. Furthermore, it offers:

- Quick mold changes for flexible production.

- Long-term durability.

- Technical service and engineering support.

- 100% compatibility with other line solutions.

The Sora Machine difference is about providing not just a machine, but a complete production partnership.