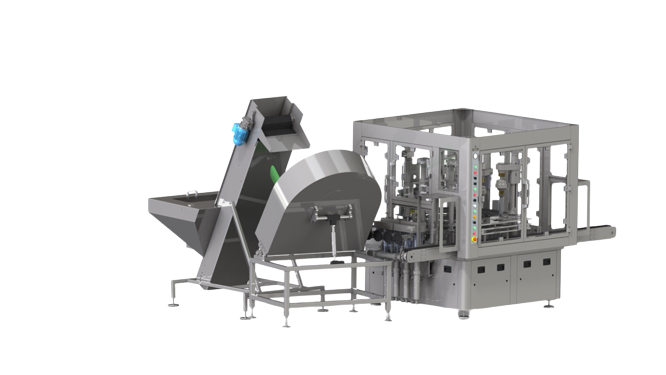

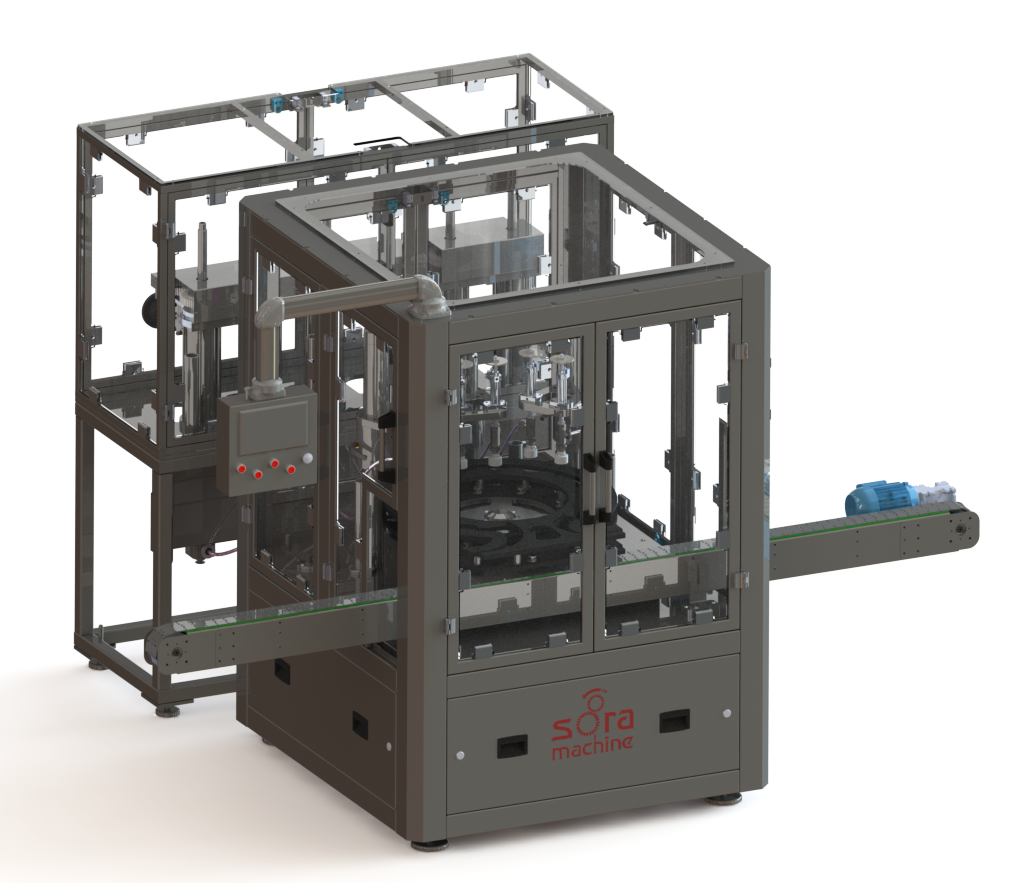

SEMI-LIQ FILLING UP TO 15 BPM Liquid Filling Machine

The SEMI-LIQ FILLING UP TO 15 BPM is an industrial-grade, continuous liquid filling machine engineered for medium-speed efficiency and durability. Operating via a Belt continuous Working System, this unit is capable of achieving an output capacity ranging from 1600 to 2400 pieces per hour. The machine construction is predominantly stainless steel, with all visible parts made from AISI 304 quality stainless steel. Furthermore, all 304 and 316 stainless steel items used throughout the machine are licensed, emphasizing material quality and hygienic standards. It is designed for operational stability, featuring a soft start and stop capability, and robust safety measures including a CE standarded Machine Protector.

Technical Advantages

- Robust Stainless Steel Construction: Features stainless construction, utilizing AISI 304 quality for all visible components. The use of licensed 304 and 316 stainless steel items ensures material integrity and compliance.

- Precision Pneumatic System: All pneumatics integrated into the system are sourced from recognized, high-quality manufacturers, including SMC, FESTO, etc..

- Optimized Utility Footprint: Requires standard Air Requirements of 6-8 bar and maintains an Air Consumption rate of 200 lt/min.

- Variable Speed Control: Incorporates stepless electronic cycle adjustment, allowing operators precise control over the machine’s operational speed.

- CE Safety Compliance: Equipped with a CE standarded Machine Protector specifically designed for working security and to maintain a clean working environment.

Used Technologies

The SEMI-LIQ FILLING UP TO 15 BPM utilizes specialized design and component integration to ensure efficiency and control:

- Continuous Belt Working System: Provides a reliable and steady platform for product conveyance throughout the filling cycle.

- Automatic Line Flow Management: The machine features a sophisticated sensor system that enables it to automatically stop when the exit is busy. This technology prevents product backups and ensures seamless integration with downstream equipment.

- Integrated Soft Start and Stop Feature: This electronic control technology minimizes mechanical stress upon startup and shutdown, contributing to the longevity of the components and reducing product spillage risks.

- Electronic Prescription Management: The system supports automatic prescription adjustment to the available products, facilitating quick and precise reconfiguration based on current production requirements.

Industrial Applications

As a general-purpose Liquid Filling Machine, the SEMI-LIQ FILLING UP TO 15 BPM is strategically designed to meet the rigorous demands of various high-standard manufacturing sectors. Based on the manufacturer’s expertise and the machine’s material specifications (AISI 304/316 licensed steel), key industrial utilization areas include:

- Cosmetics: Suitable for the precise filling of semi-liquid products such as lotions, creams, and specialized cosmetic formulations.

- Pharmaceutical Sector: Its high-grade, licensed stainless steel construction (304 and 316) makes it ideal for environments requiring strict hygienic protocols and non-reactive materials.

- General Industrial Filling: Applicable for any industrial environment requiring controlled, medium-speed filling of semi-liquid substances.

Operational Benefits

The machine prioritizes operational efficiency, maximizing uptime and simplifying routine tasks:

- High Changeover Speed: Engineers benefit from a fast transition in bottle interval, significantly reducing setup time when switching between product sizes or formats.

- Minimized Downtime: The design includes in short time changeable spare parts, enabling rapid replacement and repair when required.

- Maintenance Simplicity: The machine is specifically designed for easy service and maintenance access, reducing labor hours associated with routine upkeep.

- Process Stability: The soft start and stop feature ensures gentle handling of mechanical components and products, leading to fewer filling errors and greater component lifespan.

- Enhanced Safety and Cleanliness: The CE standarded Machine Protector not only increases working security for operators but also helps keep clean the environment.

Competitive Differentiation

This liquid filling machine distinguishes itself through its commitment to component quality, intelligent automation, and flexibility:

- Certified Material Quality: Unlike standard machines, this unit uses licensed 304 and 316 stainless steel items. This certification provides verifiable assurance of material consistency and hygienic compliance, crucial for regulated industries.

- Premium Component Integration: Utilizing pneumatics exclusively from industry leaders such as SMC and FESTO ensures superior long-term reliability and readily available technical support for critical moving parts.

- Intelligent Production Flow Management: The ability to automatically stop when the exit is busy serves as a critical automation feature, proactively preventing product collisions and maximizing line efficiency without constant manual oversight.

- Unmatched Configurability: The combination of stepless electronic cycle adjustment and automatic prescription adjustment to the available products allows for superior tuning and rapid, automated changeovers, offering greater production agility compared to manually calibrated systems.