Why the Monoblock 40 CPM Is the Heart of a Compact Aerosol Line

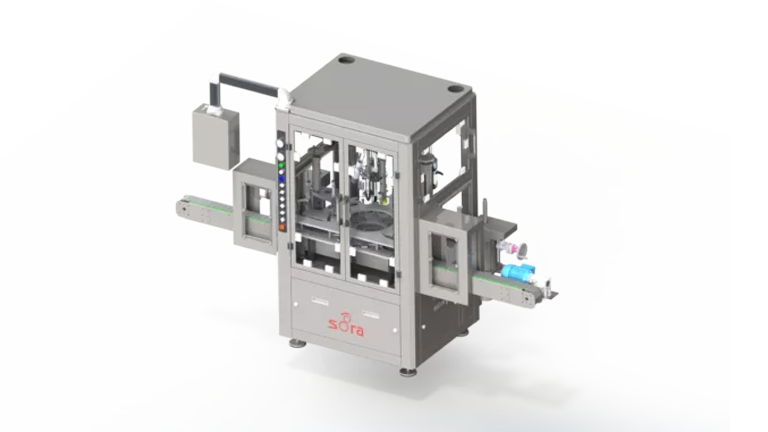

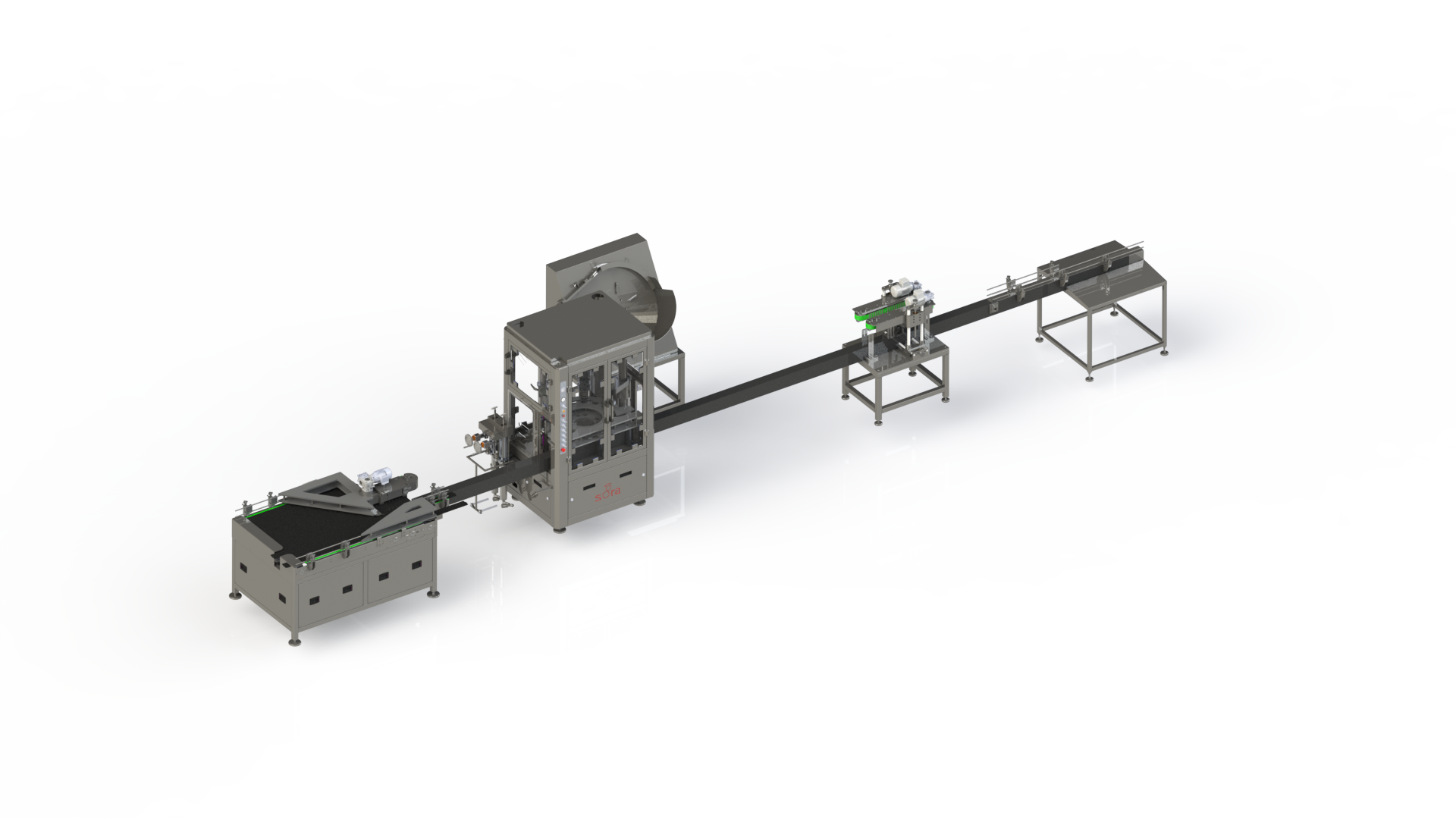

When you are trying to maximize floor space without sacrificing speed, a monoblock system is usually your best bet. This specific setup handles the entire sequence—product filling, valve fitting, sealing, and propellant injection—within a single, synchronized frame. I have noticed that many production managers struggle with the coordination between separate machines, but here, the two-head index filling and the single-head valve control work in a tight, mechanical harmony. It is designed to be a “one-stop” station that keeps your line moving at a steady 40 cans per minute, provided your container sizes fall within the 35-65 mm diameter range.

Precision and Safety: What Makes This Monoblock System Stand Out?

- Zero-Waste Dosing: You get a dosing accuracy of +/- 1%, which is critical when you are dealing with high-cost active ingredients.

- Safety Without Compromise: Every motor, sensor, and control panel on this machine is fully ex-proof (ATEX), covering both Zone 1 and Zone 2 environments.

- Static Control: You won’t have to worry about sparks or product buildup because the scrolls and guide rail covers are made from specialized anti-static materials.

- Intelligence on the Line: The “No can / no fill” feature is a lifesaver; it prevents messy spills and propellant waste if a container fails to arrive at the station.

- Versatile Capacity: With product cylinders reaching up to 300 ml and propellant cylinders up to 400 ml, you have enough range to cover most standard consumer aerosol sizes,.

The Core Technology: How ATEX Compliance and Anti-Static Design Protect Your Floor

The real genius of this machine lies in its electrical and material engineering. We are looking at a full AISI 304 stainless steel construction, which gives you the durability needed for 24/7 operations and easy washdowns. But the technical edge comes from the ATEX HMI control panel and button boxes. Since you are likely working with flammable propellants, having every single button and PLC component rated for explosive zones is a non-negotiable safety standard that this machine meets head-on. Even the plastic covers on the guide rails are chosen for their anti-static properties to ensure smooth movement without electrical interference.

Where You’ll See This Machine in Action: From Cosmetics to Industrial Sprays

If your facility is churning out hairsprays, deodorants, or even technical lubricants, this monoblock unit is tailored for your needs. It is built to be “suitable for all types of aerosol cans,” meaning you aren’t locked into one specific supplier’s packaging. Because it can handle diameters from 35 mm to 65 mm, it’s perfect for lines that switch frequently between travel-sized products and standard industrial cans.

Running the Line: Practical Gains for Your Production Team

From an operational standpoint, the biggest win is the centralized control. Your operators aren’t running between three different machines to check settings; everything is managed through the ATEX HMI. This reduces the learning curve and minimizes human error during changeovers. Also, the monoblock design means fewer transfer points between machines, which is where most can-toppling accidents happen. It’s a stable, rugged piece of equipment that prioritizes both the safety of your team and the consistency of your output.

Technical Specifications

| Feature | Industrial Specification (Example Values) |

|---|---|

| Filling Heads | 2 Heads Product / 1 Head Propellant |

| Valve Fitting/Sealing | 1 Head Fitting / 1 Head Sealing |

| Dosing Accuracy | +/- 1% |

| Can Diameter Range | 35 – 65 mm |

| Product Cylinder Capacity | Up to 300 ml |

| Propellant Cylinder Capacity | Up to 400 ml |

| Material | AISI 304 Stainless Steel |

| Safety Standard | ATEX (Ex-proof) Zone 1 & 2 |

| Control System | ATEX HMI & PLC |