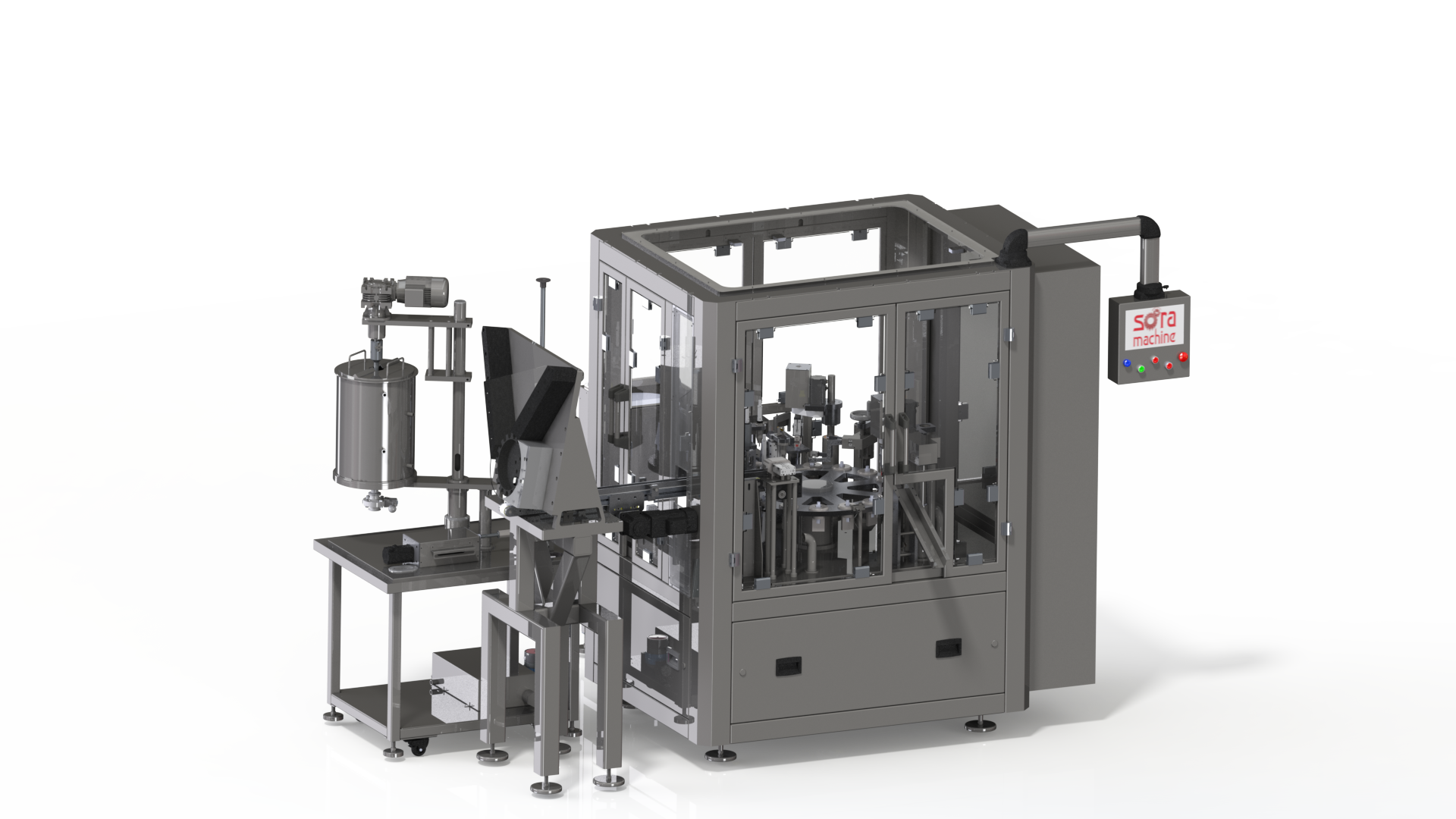

Sora Machine Monoblock Mascara Filling Station: Integrated Precision and High-Speed Cosmetic Production

The Monoblock Mascara Filling Station is a highly sophisticated, fully automated system engineered for the demanding requirements of cosmetic filling operations, delivering throughput up to 40 BPM (Bottles Per Minute). This compact, single-frame machine utilizes an Indexing turning table with a drive unit to sequentially manage all processes, from filling to capping and final discharge. Key to its accuracy is the Servo controlled Volumetric filling (Jacket type dosing unit) and the specialized Servo motor Cap tightening device with torque controller, ensuring dosage consistency and seal integrity. Product supply is managed by a Portable Stainless steel pressure type bulk vessel (30L) with safety relief valves. The entire operation is controlled and monitored via an Electrical control unit with Mitsubishi touch screen meeting.

Technical Advantages

The Monoblock Mascara Filling Station incorporates advanced features that ensure high performance and reliable operation:

- High-Speed Capacity: Optimized for MASCARA FILLING UP TO 40 BPM.

- Volumetric Accuracy: Features Servo controlled Volumetric filling utilizing a specialized Jacket type dosing unit for precise product delivery.

- Controlled Sealing: Equipped with a Servo motor Cap tightening device with torque controller, ensuring exact application torque and eliminating leaks or thread damage.

- Integrated Indexing: Utilizes an Indexing turning table with a drive unit to provide precise, intermittent container movement through the entire monoblock cycle.

- Advanced Product Supply: Includes a Portable Stainless steel pressure type bulk vessel (30L) featuring safety relief valves and a Motorized vessel raising device for efficient, controlled material handling.

- Automated Component Integration: The system handles the Brush+cap loading & feeding conveyor device (Note: specified as without unscrambling feeder) and integrates Cap seating and pre-screw functions.

- Reliable Output: Final handling uses a Bottle discharging device (Pick & Place unit) with conveyor and an Intermittent driven bottle discharging conveyor.

Employed Technologies

This system leverages cutting-edge automation and control technologies tailored for high-specification cosmetic manufacturing:

- Integrated Servo Technology: Servo motors are the core technology driving both precision Volumetric filling and critical Cap tightening. The use of a servo motor for capping allows for strict torque controller feedback, vital for product quality.

- Human-Machine Interface (HMI): System command and diagnostics are facilitated through an Electrical control unit with Mitsubishi touch screen meeting, offering reliable and industry-standard operational control.

- Jacket Type Dosing Unit: This design allows for temperature control over the product during the filling phase, which is crucial for handling viscous or temperature-sensitive mascara formulations.

- Controlled Pressure Bulk Handling: The system incorporates Stainless steel pressure type bulk vessel technology with necessary safety relief valves to manage and deliver product consistently to the dosing unit.

- Pick & Place Automation: A Pick & Place unit is utilized for controlled and gentle Bottle discharging, ensuring containers are transferred smoothly to the output conveyor.

Industrial Application Areas

The Monoblock Mascara Filling Station is purpose-built for specialized high-volume production within the beauty and personal care industry:

- Cosmetics Industry: Specifically designed for MASCARA FILLING.

- Liquid Filling Machines: Applicable within general liquid filling operations where high precision and controlled dosing of viscous products are necessary.

- Pharmaceutical and Specialty Chemical: While specialized for mascara, the technology foundation (servo volumetric dosing, stainless steel contact parts) aligns with stringent requirements in Pharmaceutical and Aerosol Filling sectors.

Operational Benefits

The technical architecture of the monoblock system translates directly into significant operational and management advantages:

- Guaranteed Quality Control: The inclusion of a torque controller on the cap tightening device minimizes product recall risk by ensuring every sealed unit meets exact specifications.

- Maximum Efficiency in Footprint: As a monoblock unit, it integrates multiple process steps (filling, cap seating, pre-screw, tightening) onto a single chassis, saving valuable factory floor space while maintaining high output up to 40 BPM.

- Simplified Material Changeover: The Portable Stainless steel pressure type bulk vessel (30L), aided by the Motorized vessel raising device, simplifies cleaning and product changes, reducing downtime.

- High Operator Confidence: The industry-recognized Mitsubishi touch screen control unit offers intuitive operation, robust error reporting, and straightforward parameter adjustments.

- Smooth Product Flow: The integrated Pick & Place unit and Intermittent driven bottle discharging conveyor ensure a seamless transition of finished product off the machine, preventing bottlenecks.

Key Differentiators from Competitors

Sora Machine’s Monoblock Mascara Filling Station differentiates itself by its dedication to integrated precision and operational support:

- Dual Servo Control Excellence: Integrating servo control not only into the filling process but also into the critical torque control capping phase provides a superior level of precision and consistency compared to systems relying on less accurate mechanical or pneumatic controls.

- Integrated Material Management: The inclusion of a complete, managed bulk system (30L Stainless steel pressure type bulk vessel with safety relief valves and Motorized raising device) reduces the complexity and ancillary equipment required for product supply.

- Specialized Focus and Performance: The machine is optimized for its specialized function, delivering reliable high-speed output UP TO 40 BPM specifically for mascara containers.

- Solution Partnership Commitment: Sora Machine is positioned as a solution partner, assuring clients that their products are in good hands, which extends beyond the hardware purchase to include reliable support and integration expertise.