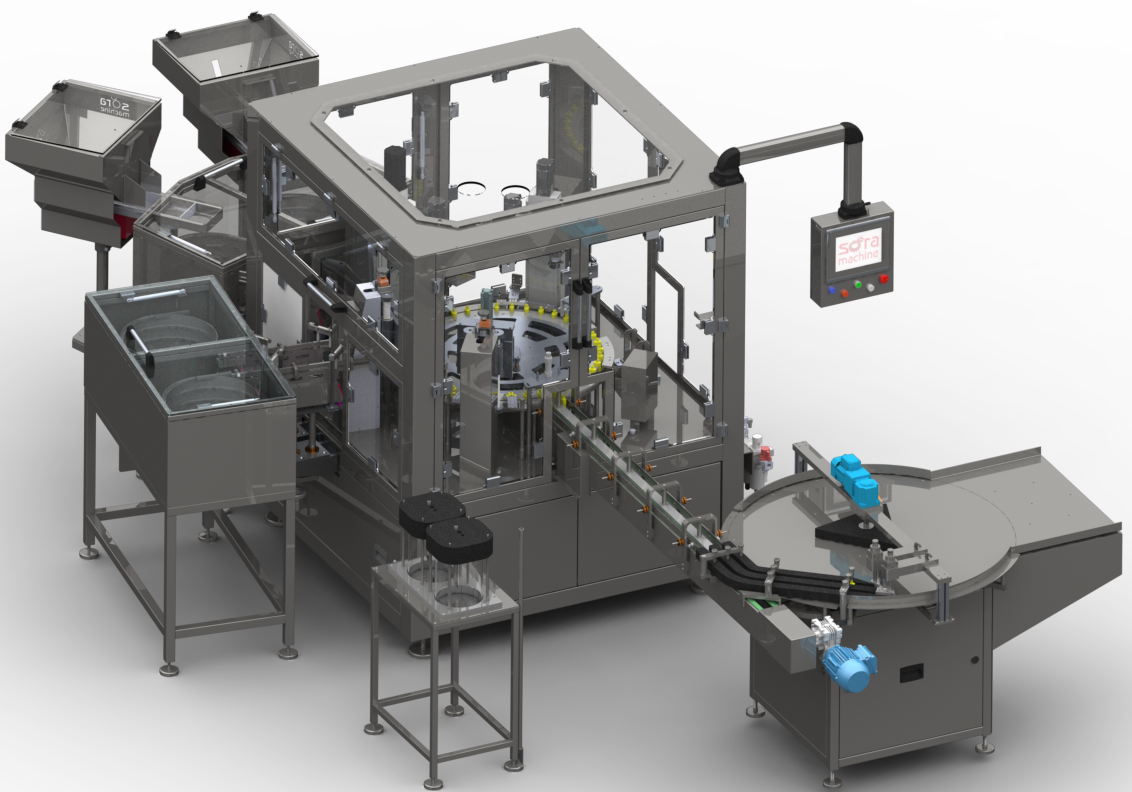

NAIL POLISH FILLING UP TO 40 BPM: Advanced Servo-Controlled Volumetric Filling System

The NAIL POLISH FILLING UP TO 40 BPM machine is a high-speed, precision liquid filling solution engineered for the cosmetics industry. Utilizing a robust, stainless steel material piston filler of the no seal type, this system guarantees accurate volumetric filing for small volumes. Driven by a 1Hp servo motor, the machine ensures precise control over both filling volume and speed, adjustable through servocontrol on the operator panel. Designed for operational efficiency, it features an easy dismantling structure and quick change capabilities for the filling head.

Technical Advantages

The machine incorporates several critical technical features that enhance precision, durability, and control:

- Seal-Free Piston Mechanism: The filling component is a stainless steel material piston filler utilizing a No seal type design, which reduces wear and potential contamination risks associated with traditional seals.

- Volumetric Precision: The system employs volumetric filing to ensure consistent and accurate dosing across the operating range.

- Wide Filling Range: Supports a functional filling range from 1-15ml, accommodating diverse small-volume nail polish containers.

- Dynamic Dispensing Control: Nozzle up/down movement is precisely managed by a Pneumatic cylinder, optimizing clean filling and reducing splashing or foaming.

- Integrated Safety Logic: Features a crucial “No-bottle, no-filling” function, preventing product waste during line interruptions or container shortages.

Used Technologies

The system relies on advanced control and mechanical technologies to achieve its high precision and speed:

- Servo Motor Drive: A Servo motor (1Hp) acts as the primary driver, offering dynamic control over the machine’s operation.

- Servocontrol System: Filling volume and speed adjustment are managed by a comprehensive servocontrolled system. This volume adjustment is executed conveniently via servocontrol on the control panel, allowing for rapid and repeatable setup changes.

- Pneumatic Actuation: A Pneumatic cylinder controls the vertical movement (up/down) of the nozzle during the filling cycle.

- Quick Change Mechanics: The system employs a Quick changeable structure specifically for the filling head, minimizing downtime during product changeovers.

Industrial Applications

This machine is primarily engineered for NAIL POLISH FILLING. Given its small filling range (1-15ml), it is ideally suited for the high-precision requirements of the cosmetics sector, particularly for high-value liquid products packaged in small volumes.

Operational Benefits

The design emphasizes operational efficiency and ease of maintenance for manufacturing environments:

- Minimized Downtime for Cleaning: Features an Easy cleaning: Flushing function, which significantly accelerates the process of sanitizing the filling components.

- Streamlined Maintenance: The entire system benefits from an easy dismantling structure, simplifying component access and maintenance procedures.

- Rapid Changeover: The quick changeable structure for the filling head allows technicians to swap components swiftly when changing nail polish color batches or product sizes.

- Waste Reduction: The inherent “No-bottle, no-filling” capability ensures product conservation and cleaner operation.

- Consistency and Throughput: The servocontrolled filling volume and speed adjuster provides the necessary precision to maintain the output rate of up to 40 Bottles Per Minute (BPM).

Differences from Competitors

While detailed competitor data is unavailable in the sources, the distinguishing features of this machine lie in its specialized design for demanding cosmetic liquids:

- Superior Material Design: The utilization of a stainless steel material piston filler (No seal type) ensures high chemical resistance and reduces potential maintenance issues associated with standard sealing components.

- Integrated Servo Precision: The dedicated 1Hp Servo motor coupled with direct servocontrol on the panel for volume adjustment provides a level of repeatability and fine-tuning precision superior to simpler mechanical or time-pressure filling systems.

- Maintenance Optimization: The combination of the easy dismantling structure, quick changeable filling head structure, and the dedicated Flushing function delivers a lower Total Cost of Ownership (TCO) by maximizing operational uptime and minimizing labor required for cleaning and changeovers.