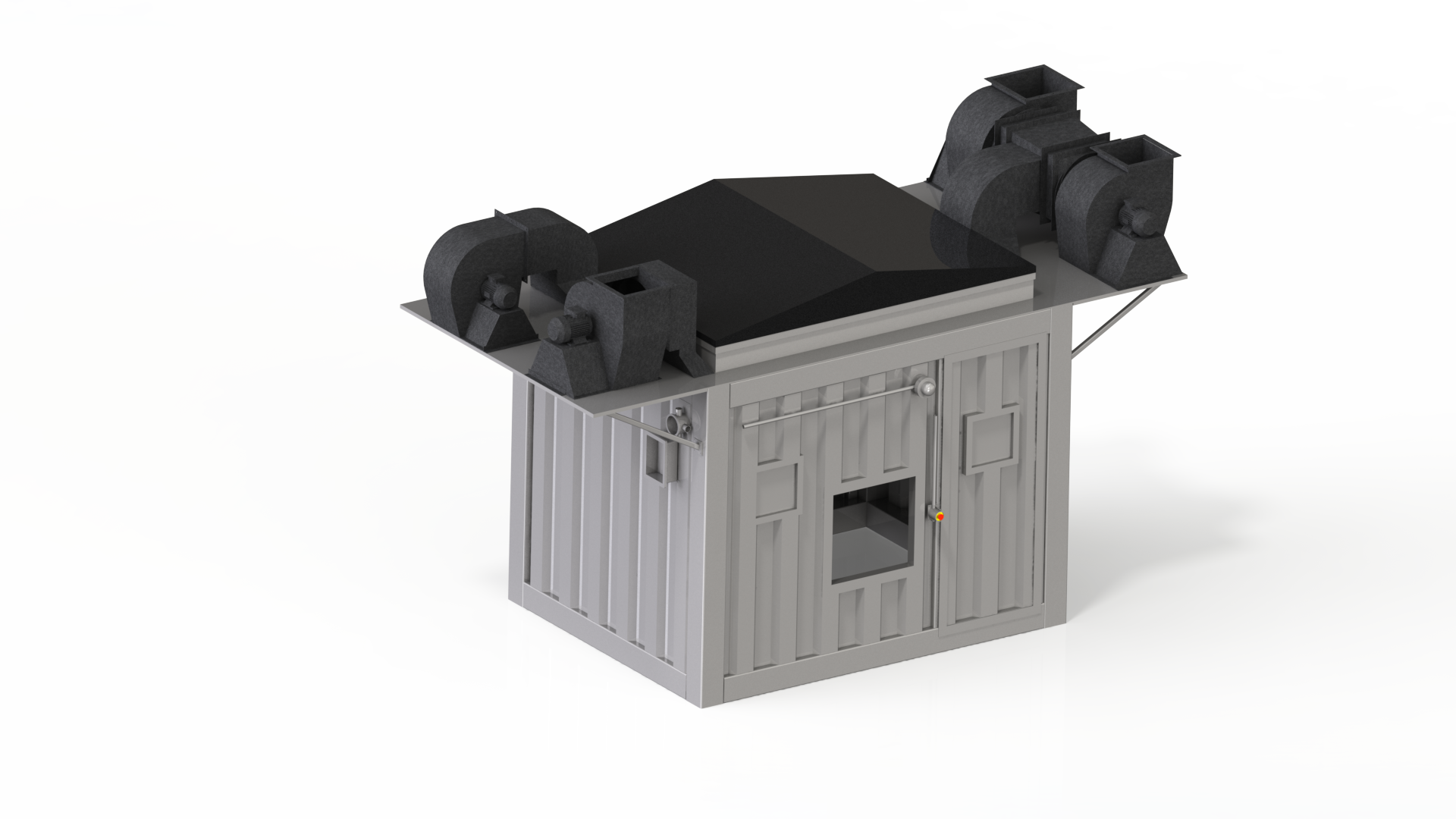

GAS HOUSE: ATEX II 2G Compliant Hydrocarbon Filling Safety Enclosure

GAS HOUSE is a specialized Standard Transportable Hydrocarbon Filling Room designed as a containerized solution for safely managing the risks associated with filling volatile gases. Rated as ATEX II 2G Compliant, this structure is specifically engineered to accommodate single rotary or indexing filling machines. It maintains operational integrity through robust construction, including insulated walls rated for a design pressure of 4.8 kN/m², and incorporates advanced safety systems—such as explosion-proof lighting and comprehensive gas and flame detection—while maintaining a crucial negative pressure inside the gas house and gasser to prevent hazardous gas escape.

Technical Advantages

- Certified Safety Compliance: Fully compliant with ATEX II 2G standards, classifying it suitable for hazardous zone operations.

- Controlled Explosion Mitigation: Features dedicated explosion relief via the roof area, which is covered with a fire retardant sheet PVC and secured by fastening rope or chain.

- Robust Structure: Built with flameproof and flame delayer paint on the structure, and insulated walls designed to withstand 4.8 kN/m².

- High-Volume Ventilation: Features two independent extraction fans on the gas house (one running continuously) and a fresh air blower, ensuring a minimum of 60 air changes per hour (normal) and up to 120 air changes per hour (high).

- Safety Interlocks: Flow sensors are installed and linked to the system to stop the filling operation immediately if a loss of ventilation flow is detected.

- Uninterrupted Critical Systems: Equipped with an UPS system to maintain power supply to critical controls in case of electricity cuts.

- Explosion-Proof Equipment: Utilizes explosion proof zone 2 fluorescent strip lighting and externally mounted, electrically controlled, ex-proof ventilation fans.

Used Technologies

- Infrared (IR3) Flame Detection: A single IR3 detector is mounted inside the unit for rapid flame identification.

- Multi-Point Infrared Gas Detection System: Includes two infrared gas detectors within the gas house and one on the gassing machine, designed to sense the presence and level of flammable Butane and Propane mixtures and automatically initiate safety functions if levels approach the Lower Explosive Limit (LEL).

- PLC-Controlled Gas Manager Panel: Features an operator control panel with a key switch for system start-up and shutdown routines, and electrical control over the ex-proof fans.

- Two-Speed Explosion Proof Fans: High-performance, 2.2 Kw-380VAC-3ph-50Hz motors power the primary, secondary, and fresh air systems, providing adjustable air displacement volumes.

- Isolation Systems: Features one automatic and manual isolation valve externally (as close as possible) and one manual isolation valve inside the gas house for controlled shutdowns.

Industrial Applications

This specialized enclosure is essential for any industrial process involving the safe handling and filling of flammable hydrocarbons (Butane/Propane). Relevant sectors include:

- Aerosol Filling Operations: Specifically sized to accommodate single rotary or indexing filling machines used in aerosol production.

- Pharmaceutical Manufacturing: Used in processes requiring gas handling, potentially related to sterilization or pharmaceutical aerosol packaging.

- Cosmetics Production: Applicable to the filling of aerosol cosmetic products.

Operational Benefits

GAS HOUSE significantly enhances operational safety and compliance in hazardous filling environments, offering reliable containment and control.

- Maximized Containment Security: The robust, containerized structure and continuous negative pressure environment ensure that dangerous hydrocarbon vapors remain contained, protecting surrounding personnel and facilities.

- Assured Ventilation Performance: The dual-speed ventilation system guarantees swift air turnover, maintaining low gas concentrations with up to 120 air changes per hour, crucial for working within safe explosive limits.

- Minimization of Human Error: PLC control and key safety devices (isolation valves, flow sensors) are integrated to automate critical safety responses, reducing reliance on manual intervention.

- Optional Remote Visualization: The optional CCTV camera, contained within an explosion-proof enclosure, allows operating personnel to safely monitor the gassing machine from a non-hazardous area via a remote color monitor.

Technical Specification Table

| Characteristic | Value/Rating | Unit |

| Type | Standard Transportable Hydrocarbon Filling Room | – |

| Compliance Rating | ATEX II 2G | – |

| Exterior Dimensions (L x W x H) | 3000 x 3000 x 2500 | mm |

| Wall Design Pressure | 4.8 | kN/m² |

| Minimum Air Changes (Normal) | 60 | /hr |

| Maximum Air Changes (High) | 120 | /hr |

| Total Gas Detectors | 3 | pcs |

| Flame Detector Type | Infrared (IR3) | pc |

| Primary Ventilation Flow (Gas House, High Speed) | 2950 CFM [8000 m³/h] (Sample) | Airflow |

| Fan Motor Specification (Example) | 2.2 Kw, 380 VAC, 3ph, 50 Hz | Electrical |

GENERAL

- Type : Standard Transportable Hydrocarbon Filling Room

- Construction : Container

- Rating : ATEX II 2G Compliant

- Sized for : Single Rotary/Indexing Machines

- Design Pressure :4,8 kn/m2 on all Four Insulated Walls

- Explosion Relief : Roof Area

- Roof : Fire retardant sheet PVC roofing cover and secured on the roof with fastening rope or chain

- Paint of structure: Flameproof and flame delayer

- Lighting : Explosion proof zone 2 fluorescent strip lighting

- Egress doors: 2 pcs on sides

- Windows: 2 laminated

- Windows for conveyor belts: 2 pcs or 1 pcs (depends on line lay-out)

- Fire fighting : One fire extinguishing ball is mounted inside the gas house

- Flame detector: 1 infrared (IR3)

- Gas detector: 2 pcs infrared (gas house) , 1 pcs infrared (gassing machine)

- UPS system in case electricity cuts

- One automatic and manual isolation at the outside of gas house (as close as possible), one manual isolation valve inside the gas house

- The pressure inside the gas house and gasser will be kept in negative pressure

PHYSICAL

- Width 3000 mm

- Length 3000 mm

- Height 2500 mm

VENTILATION

- The gas manager panel has a PLC panel containing the operator controls and indicators. A key switch is provided to enable the start and stop push buttons. This is used during the system start up and shutdown routines.

- Two independent extration fans (on gas house); one runs continuously

- One extration fan (on the gasser)

- One fresh air blower

- The fans are mounted externally on a fabricated steel platform. They are connected to the internal primary and secondary ventilation ducting through the gassing room wall, and to the external ducting. The fans are ex-proof and electrically controlled through the gas manager, and are connected to the gas manager.

- Ventilation ensures a minimum of 60 air changes per hour (normal) and a minimum of 120 air changes per hour (high)

- Flow sensors are installed and linked to the stop filling in case of loss of flow is detected

Primary ventilation system for gasser machine

- Fans : 2-Speed Explosion Proof Fan

- Rating : 2950 CFM [5000m3] at 1400 RPM,1475 CFM [2500 m3] at 700 RPM

- Motor : 2.2 Kw-380VAC-3ph-50Hz

Primary ventilation system for gas house

- Fans : 2-Speed Explosion Proof Fan

- Rating : 2950 CFM [8000m3/h] at 1400 RPM,1475 CFM [4000 m3/ h] at 700 RPM

- Motor : 2.2 Kw-380VAC-3ph-50Hz

Secondary ventilation system for gas house

- Fans : 2-Speed Explosion Proof Fan

- Rating : 2950 CFM [5000m3/h] at 1400 RPM,1475 CFM [2500 m3/ h] at 700 RPM

- Motor : 2.2 Kw-380VAC-3ph-50Hz

Fresh air blowing system

- Fans : 2-Speed Explosion Proof Fan

- Rating : 2950 CFM [4000m3] at 1400 RPM,1475 CFM [2000 m3] at 700 RPM

- Motor : 2.2 Kw-380VAC-3ph-50Hz

ROOF

- Fire retardant sheet PVC roofing cover and it is designed to prevent flying parts from escaping the confines of the gas house.

- The roof is secured to the gas house by elasticated roof fastening rope or chain

CCTV CAMERA AND MONITOR OPTION

- A color camera is mounted inside the gas house, above the large access door. This camera, when selected, is contained within an explosion proof enclosure, and monitors the gassing machine operation. An optional remote color monitor, located in a non-hazardous area, provides visualization of the gassing machine to operating personnel.

GAS DETECTION SYSTEM

- The gas sensors indicate the presence and level of gas and automatically initiate safety functions. Butane and propane mixtures with air are flammable within the explosive limits which are between approximately 1.8% to 10% v/v. The lower figure is called the lower explosive limit (LEL).