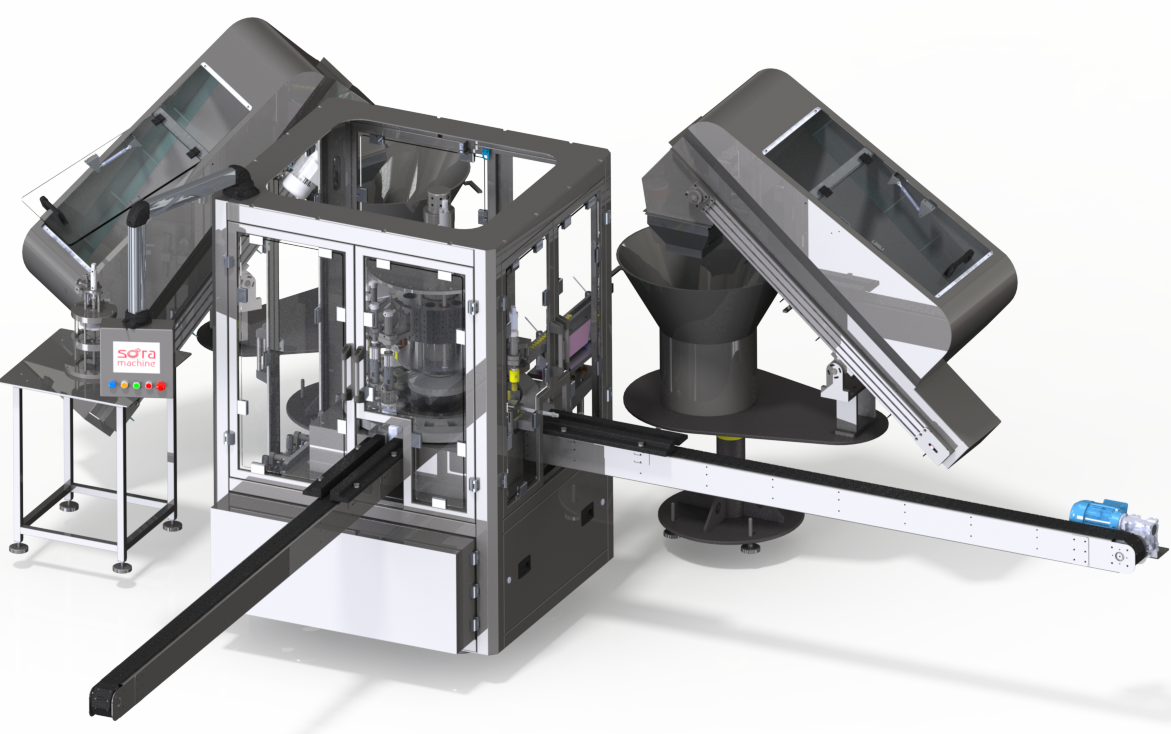

Monoblock Perfume Filling Machine with Valve & Cap Placing

Monoblock Perfume Filling Machine with Valve & Cap Placing is a fully integrated, high-performance solution designed for the automated filling, valve insertion, and capping of liquid products, particularly within the fragrance and cosmetics industry. Engineered for efficiency and precision, this unit is capable of achieving production rates of up to 30 pieces per minute when processing 150–200 ml product sizes. Constructed primarily from AISI 304 stainless steel, with product contact parts available in AISI 316 or AISI 304 specifications, the machine guarantees a strict dosing accuracy of +/- 1%, ensuring minimal product wastage and consistent quality across all production batches.

Technical Advantages

The machine offers robust specifications designed for demanding industrial operations:

- High-Speed Output: The proposed machine is optimized to deliver a top operating speed of up to 30 pieces per minute, based on product volumes ranging between 150 ml and 200 ml.

- Volumetric Precision: Ensures accurate and consistent liquid dosing with an ultra-tight tolerance of +/- 1%.

- Premium Construction Material: The main machine structure is built using AISI 304 stainless steel, providing durability and resistance to harsh factory environments.

- Pharmaceutical Grade Contact Surfaces: Components that interface directly with the liquid product are specified as AISI 316 or AISI 304, fulfilling strict regulatory and hygiene requirements for high-purity liquids.

- Integrated Safety Clutch System: The entire machine is equipped with a clutch system to provide instant protection to mechanical parts in the event of any bottle jamming incidents, significantly reducing potential damage and costly downtime.

Technologies Used

The machine incorporates globally recognized, high-quality industrial components to ensure reliable automation and simplified maintenance protocols:

- Advanced Electronic Instrumentation (PLC): The Programmable Logic Controller (PLC) and all associated electronic instrumentation utilize premium, industry-standard brands such as ALLEN BRADLEY, SIEMENS, or OMRON, or other similar quality brands. This selection guarantees long-term support, simplified integration into existing factory systems, and reliable control over complex monoblock functions.

- High-End Pneumatic Components: Critical actuation and motion control functions are managed by pneumatic instruments sourced from leading manufacturers, specifically SMC, FESTO, or equivalent quality brands. This ensures precise, repeatable pneumatic operation required for high-speed filling, valve placing, and capping actions.

- Safety Interlocks: For operational safety and maintenance accessibility, all machine cabinets are fitted with independent on/off switches.

Industrial Usage Areas

This monoblock solution is primarily tailored for industries requiring the precise, sanitary, and integrated handling of high-value liquid products:

- Fragrance and Perfume Manufacturing: Ideal for high-speed filling and precise closure (valve/cap placing) of specialized perfume bottles.

- Cosmetics Industry: Suitable for filling high-quality liquid cosmetic products requiring stringent dosing accuracy and sanitary contact materials.

- Specialized Liquid Filling: Applicable to other high-purity or sensitive liquid products that benefit from the corrosive resistance of AISI 316/304 contact parts and precise volumetric control.

Operational Benefits

Integrating this monoblock system yields tangible operational and financial advantages:

- Reduced Product Loss: The specified +/- 1% dosing accuracy minimizes volumetric inconsistencies, directly translating to a reduction in high-value product giveaway.

- Maximized Production Flow: The monoblock design integrates three critical steps (filling, valving, capping) into a single compact unit, reducing line transfers and potential bottlenecks, while the 30 pcs/min speed ensures high throughput.

- Damage Control and Uptime: The mandatory clutch system protects the machinery from severe mechanical strain during jams, radically decreasing repair costs and maximizing production uptime.

- Ease of Global Support: Leveraging globally standardized components from brands like ALLEN BRADLEY, SIEMENS, FESTO, and SMC ensures readily available spare parts and compatibility with existing engineering expertise globally, simplifying maintenance and service.

Differentiation from Competitors

This system distinguishes itself through its commitment to quality materials and premium component standardization:

- Integrated Safety Assurance: The inclusion of a machine-wide clutch system specifically designed to mitigate damage from jamming bottles offers superior protection and reliability compared to systems relying solely on electronic overload detection.

- Standardized Tier-One Components: We mandate the use of recognized, top-tier brands (e.g., ALLEN BRADLEY, SIEMENS, OMRON for control systems; SMC, FESTO for pneumatics). This commitment eliminates the risk associated with unverified components, offering factory managers peace of mind regarding long-term reliability and component sourcing.

- Material Specification for High-Value Goods: Utilizing high-grade AISI 316 or AISI 304 for all product contact parts exceeds basic industry standards for many applications, confirming suitability for the most critical and corrosive liquid filling requirements.