What is a Palletizing Machine and Why is it Used in Industrial Production?

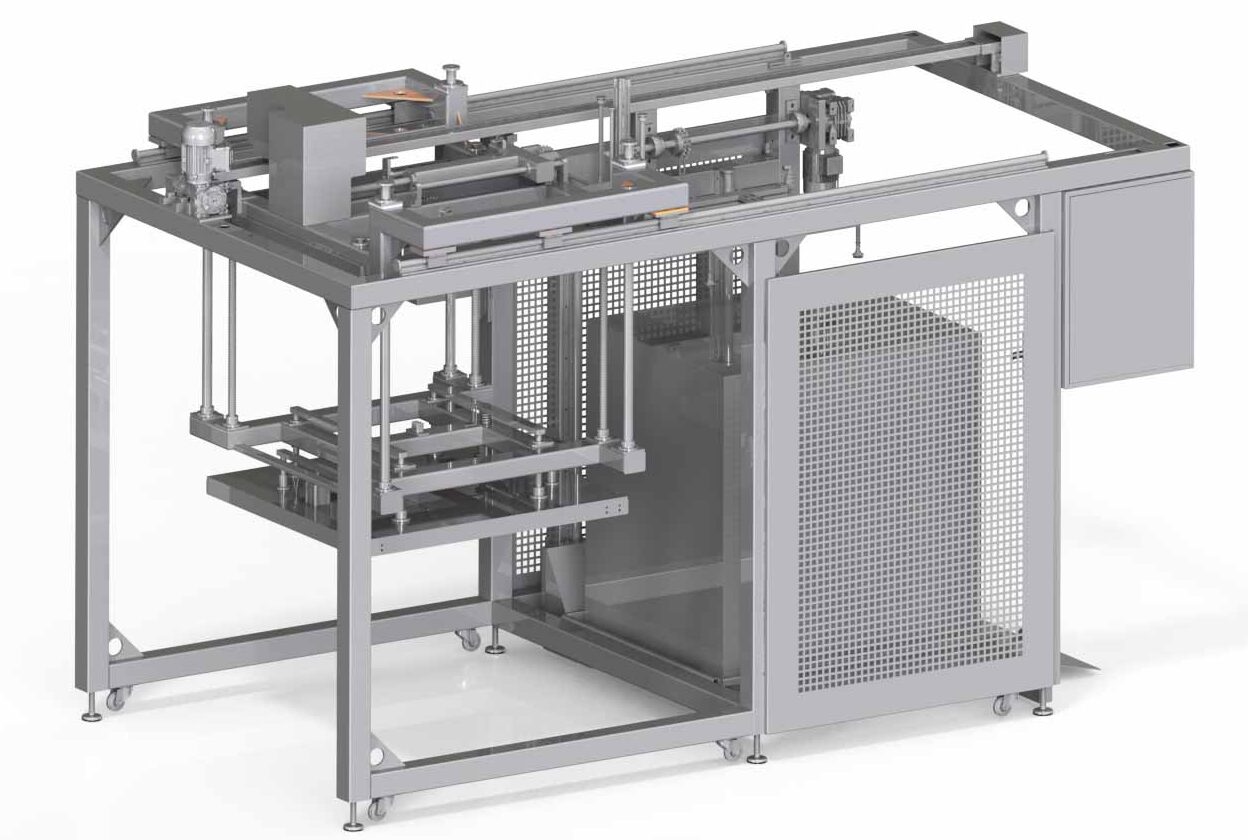

Palletizing machines are automation systems that arrange products such as boxes, bags, packages, or drums coming off the production line onto a pallet in a specific order, making them ready for transport. These machines increase occupational safety by eliminating heavy lifting, standardize product placement, and accelerate logistics processes. Sora Machine palletizing systems are equipped with high-precision robotic arms, servo-assisted mechanisms, and sensor-based control systems. This ensures both a fast and smooth stacking process.

In Which Sectors are Palletizing Machines Used?

Palletizing solutions are widely used in a broad range of industries including food, beverage, cosmetics, chemicals, pharmaceuticals, automotive, and construction materials. Sora Machine analyzes the specific needs of each sector and offers palletizing systems suitable for a wide variety of product formats, from milk cartons to paint buckets, detergent boxes to glass bottles. This diversity increases the flexibility of production processes.

What Advantages Do Robotic Palletizing Systems Offer?

Unlike traditional mechanical systems, robotic palletizing systems quickly adapt to product diversity. 4-axis or 6-axis industrial robots can dynamically detect and quickly stack products of different sizes. The robotic solutions offered by Sora Machine can automatically adjust based on parameters such as product size, weight, and pallet pattern through advanced software. This reduces the need for human intervention during production and prevents incorrect palletizing.

What Should Be Considered When Choosing a Palletizing Machine?

To choose the right palletizing machine, product type, production speed, available space, and the targeted level of automation should be considered. Additionally, technical details such as the machine’s PLC control system, SCADA integration, safety equipment, and user interface play a decisive role in the selection. Sora Machine provides customized project planning for each customer, determines the system that will provide maximum efficiency, and offers post-installation support services for sustainability.

How are Palletizing Machines Integrated into the Production Line?

Modern palletizing systems are integrated at the end of production lines, following systems such as shrink wrapping, labeling, or weighing. Sora Machine’s palletizing solutions can work in full integration with conveyor systems, automatic empty pallet dispensers, and stretch wrapping machines. This way, after the product exits the production line, it is ready for shipment without requiring any manual handling. This structure saves time and ensures continuity in production.

How Does Automatic Pallet Feeding Work in Palletizing Machines?

Automatic pallet feeding systems continuously monitor the pallet stock and bring a new pallet to the stacking area when needed. These systems ensure continuous palletizing without operator intervention. The smart sensors and software developed by Sora Machine check whether the pallets are in the correct position and make the necessary adjustments automatically. This allows businesses to achieve significant savings in terms of both time and labor.

Are Palletizing Systems Compatible with Industry 4.0?

Yes, Sora Machine palletizing systems are fully compatible with the Industry 4.0 infrastructure. The systems work in integration with SCADA, MES, and ERP platforms, providing real-time data tracking and production reporting. This allows businesses to monitor production efficiency, receive instant malfunction notifications, and analyze critical information such as energy consumption. Furthermore, remote access capability enables faster technical support.

What are the Safety Measures in Palletizing Systems?

Occupational safety is one of the highest priorities in palletizing machines. Sora Machine’s systems are equipped with emergency stop buttons, light curtains, safety cages, and operator recognition systems. Additionally, machine working areas are protected by safety sensors, and the system automatically stops in case of any risk. This ensures both operator safety and protects the machine’s lifespan.

Why Should Sora Machine Palletizing Solutions Be Preferred?

Sora Machine offers customized solutions for each project with an engineering approach centered on customer needs. Systems customized according to product variety, production volume, and facility space provide maximum performance while occupying minimal space. With advantages such as the use of high-quality components, long-lasting design, fast service support, and compliance with international certifications, Sora Machine makes a strong contribution to competitive production processes.

Depalletizing Systems: Automation at Raw Material Infeed

Depalletizing systems are located at the beginning of the production line and automatically feed products such as boxes, bottles, drums, or bags that arrive on pallets to the lines. Especially in high-volume production facilities, they ensure the smooth and rapid integration of raw materials or semi-finished products into production. Sora Machine’s depalletizing solutions offer flexible and safe use for different product types. These systems, together with palletizing, create a bidirectional automation chain, ensuring an uninterrupted flow throughout the entire production process.