What Is A Perfume Filling Machine And How Does It Work?

Perfume filling machines are industrial equipment that ensures the precise and hygienic transfer of liquid perfume products into bottles. These machines are generally designed to work with low-viscosity liquids and offer different levels of automation, from manual to fully automatic. Sora Machine’s perfume filling lines are equipped with servo motor systems that provide high filling accuracy. Thanks to these systems, the desired amount of product is filled into each bottle completely.

Which Bottle Types Should Be Considered When Choosing Perfume Filling Machines?

Perfume bottles of different volumes and shapes can create difficulties in production processes. Therefore, machines with a modular and flexible design that can quickly respond to bottle changes are important. Sora Machine filling systems adapt to a wide range of bottles, from 30 ml to 200 ml, with interchangeable mold sets and adjustable conveyor systems. This flexibility offers significant advantages for manufacturers with high product diversity.

What Are The Advantages Of Automation In A Perfume Filling Line?

Fully automatic perfume filling lines integrate not only the filling process but also steps such as spray cap placement, cap pressing, and labeling. Equipped with vision control systems, these lines detect faulty products and separate them from production. Automation reduces labor costs while increasing production speed and quality standards. Sora Machine solutions offer this integrated structure with user-friendly interfaces.

Why Are ATEX Certified Machines Important In Perfume Production?

Alcohol and similar volatile substances used in perfume production pose an explosive atmosphere risk. Therefore, it is vital that the production line is ATEX certified. Sora Machine perfume filling machines are designed in accordance with ATEX directives. Special insulated cabins, antistatic systems, and controlled air circulation features are integrated to provide a safe production environment for operators working in potentially explosive areas.

How Hygienic Are Perfume Filling Machines?

In cosmetic production, hygiene is as important as product quality and brand reliability. Therefore, it is important for filling machines to be compatible with CIP (Cleaning-in-Place) systems. In Sora Machine machines, all surfaces in contact with liquid are made of stainless steel and joined with hygienic welds. Cleaning processes can be performed quickly, effectively, and without production interruptions.

How Fast Can A Perfume Filling Line Operate?

Production capacity is a critical factor for both small businesses and high-volume brands. Sora Machine filling lines can achieve a filling capacity of 30 to 120 bottles per minute. Servo motor-supported systems minimize product loss during filling while maintaining a constant filling speed. Speed and accuracy are offered together in these machines.

Are Perfume Filling Machines Compatible With Industry 4.0?

Digitalization is of great importance in modern production lines. Sora Machine’s perfume filling systems work in full integration with SCADA and IoT infrastructures. Production processes can be optimized thanks to features such as remote monitoring, automatic production reporting, fault diagnosis systems, and data analysis. This provides businesses with efficiency, traceability, and flexibility.

What Are The Quality And Safety Certificates For Perfume Filling Machines?

All of Sora Machine’s production solutions are manufactured in accordance with CE and ATEX standards. They are also compliant with GMP (Good Manufacturing Practices) standards. Thanks to these certificates, the machines can be used safely in both local and international markets. Each production line undergoes quality control tests before shipment and is delivered with a long-life operation guarantee.

Why should You Choose Sora Machine Perfume Filling Systems?

Sora Machine stands out in the field of perfume filling machines with its sector experience, engineering strength, and customer-oriented approach. Thanks to our capacity to develop customized solutions, we offer scalable solutions to both boutique manufacturers and global cosmetic brands. We also make a difference with our fast and sustainable service approach regarding after-sales technical support and spare parts supply.

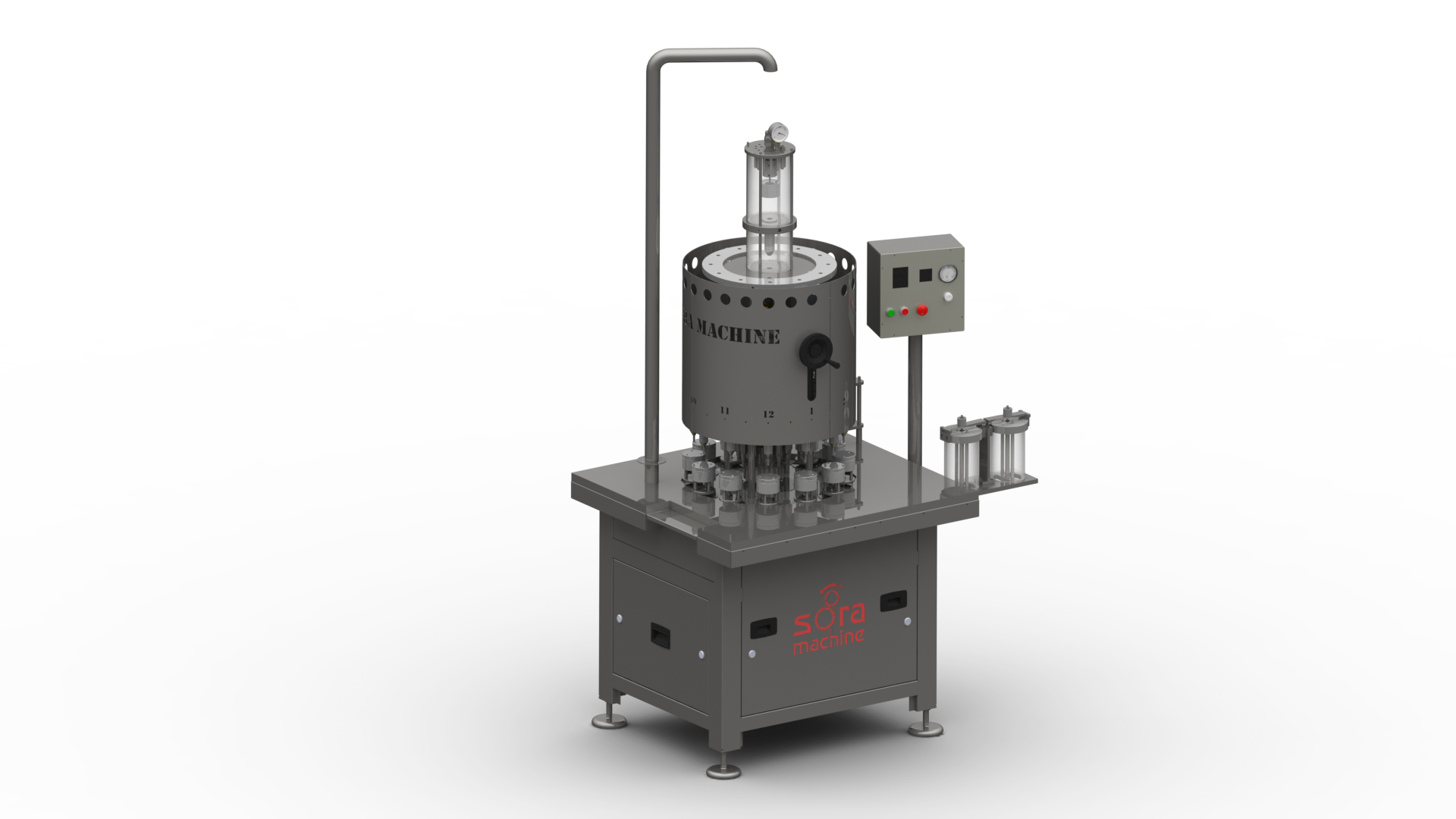

What Is A Rotary Perfume Filling Machine And What Advantages Does It Offer?

Rotary perfume filling machines are designed for high-capacity production needs. Bottles move on a rotary table to fixed stations, undergoing filling, spray placement, pressing, and capping processes sequentially. Sora Machine’s rotary systems complete processes in seconds, providing maximum efficiency for large-volume production lines. While saving space due to their compact design, they offer stable and precise results even at high speeds.

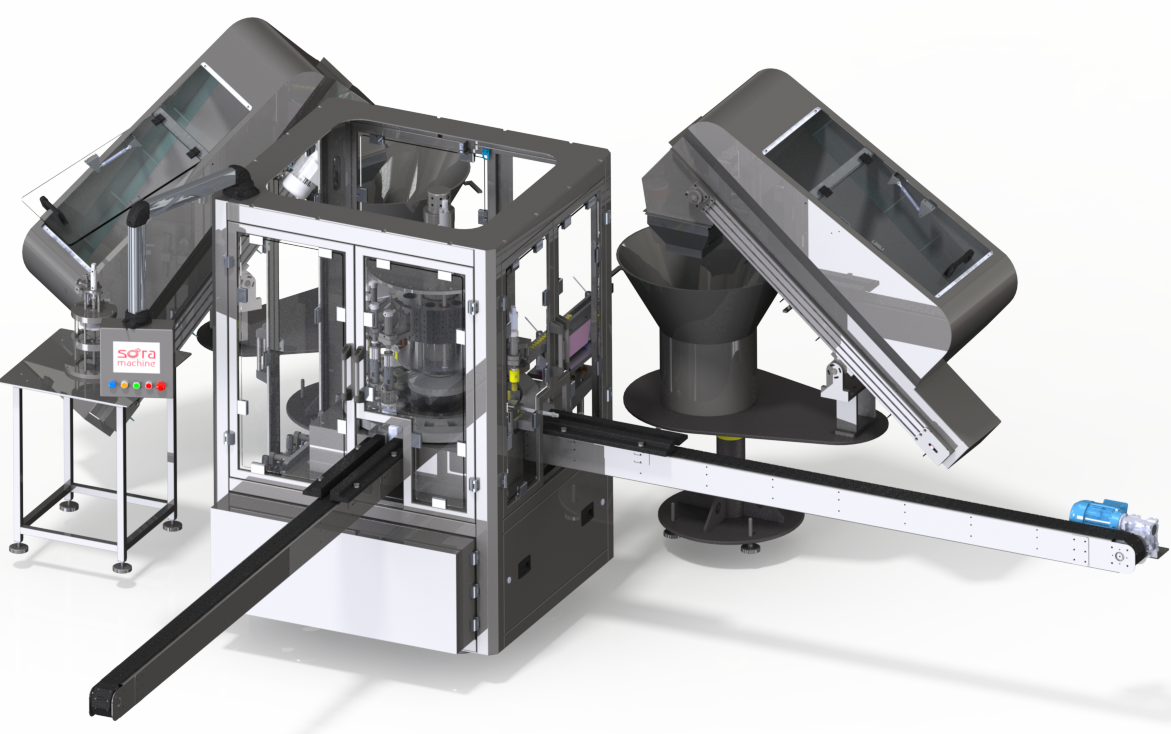

For Which Manufacturers Are Monoblock Perfume Filling Machines Ideal?

Monoblock systems combine all production steps in a single compact body, offering practical and integrated solutions for medium-sized manufacturers. In these machines, filling, spray assembly, capping, and control systems operate on a single platform. Monoblock perfume filling machines, which save both space and labor, stand out with their flexible structure that can adapt to different product variations. Sora Machine’s monoblock solutions meet high-quality standards with their safe, hygienic, and user-friendly design.