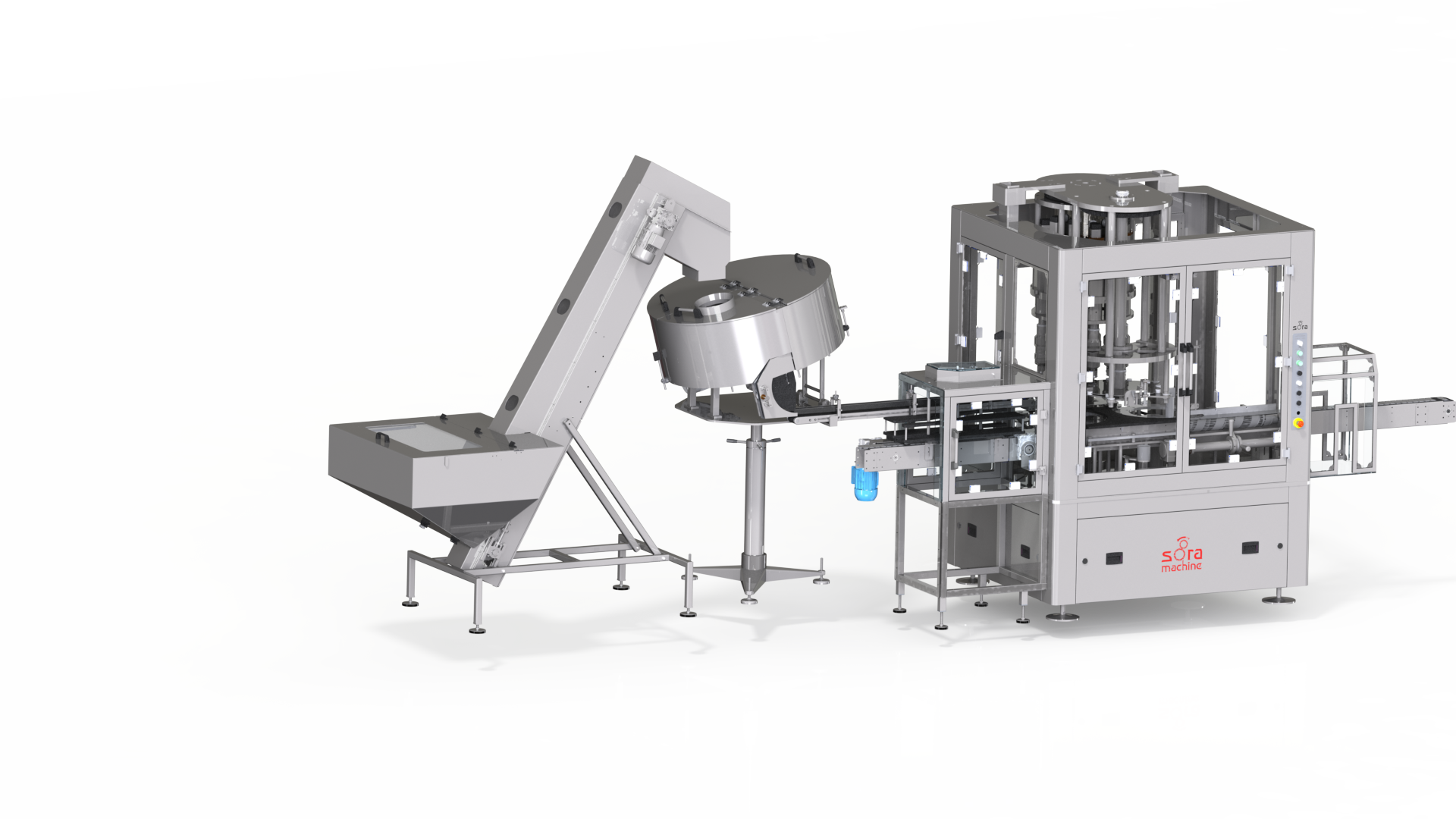

PUMP SORTING AND FITTING SYSTEM

Pump Sorting And Fitting machine is a fully integrated, automated solution designed for high-precision packaging lines. It executes the critical functions of automatic sorting of pumps, followed by their automatic inserting and tightening onto containers. Engineered for durability and strict hygiene standards, the unit is constructed entirely from 304 SS Stainless Steel. To ensure safe operation within industrial environments, the machine incorporates safety restriction boxes at the in-out points, making it a reliable and compliant component for aerosol, liquid, and cosmetics packaging operations.

Technical Advantages

- Integrated Automation Cycle: Provides comprehensive automation covering the full closure process: sorting, inserting, and tightening of pumps.

- High-Grade Construction Material: Built using 304 SS Stainless Steel, offering superior resistance to corrosion and facilitating stringent cleaning protocols required in pharmaceutical and cosmetic industries.

- Precision Pump Handling: Ensures the consistent orientation and accurate automatic inserting of pumps, minimizing defects and ensuring product integrity.

- Controlled Tightening Mechanism: Features an automatic tightening capability necessary for applying consistent torque, thus guaranteeing a secure, leak-proof seal across all packaged products.

- Dedicated Safety Features: Includes mandatory safety restriction boxes at the in-out of the machine, enhancing operational security and compliance with industrial safety mandates.

Utilized Technologies

Since the sources focus on the functionality and construction rather than proprietary technologies, the description below is based on the inherent technical actions confirmed by the sources:

- Automated Component Orientation: Technology used for the automatic sorting of pumps, which is essential for presenting components correctly to the insertion mechanism.

- Electro-Mechanical Insertion System: Dedicated mechanisms enable the precise, repeatable automatic inserting of pumps into the container necks.

- Torque Control System: The inclusion of automatic tightening of pumps indicates a system capable of managing closure force consistently, vital for maintaining product specifications.

- Industrial Material Technology: The selection of 304 SS Stainless Steel represents the utilization of material technology that maximizes equipment lifespan and sanitary compatibility in industrial filling environments.

Industrial Applications

The PUMP SORTING AND FITTING machine is an integral component for manufacturers focusing on high-volume production where precise pump application is mandatory. Applicable sectors include:

- Cosmetics and Personal Care: Used in filling lines for lotions, creams, serums, and other cosmetic liquids where hygienic packaging and precise pump dispensing are critical.

- Pharmaceuticals: Applicable for securing closures on medical or health-related liquids, relying on the 304 SS Stainless Steel construction for sanitation and compliance.

- Aerosol Manufacturing: Serves as a key component within comprehensive filling and packaging lines (such as those offered by Sora Machine) alongside liquid filling and labeling systems.

- Chemical and General Liquid Filling: Suitable for any operation requiring reliable, high-speed automated pump insertion and consistent tightening.

Operational Benefits

- Optimized Production Efficiency: Automating the sorting, inserting, and tightening process eliminates manual bottlenecks, leading to higher throughput rates and substantial production capacity increases.

- Consistent Quality Control: Automated tightening ensures every container seal meets exact specifications, drastically reducing variations in product quality and minimizing rejects due to poor closure integrity.

- Compliance and Safety Assurance: The use of 304 SS Stainless Steel supports stringent GMP/HACCP standards, while the safety restriction boxes protect personnel, leading to enhanced regulatory adherence and reduced operational risk.

- Reduced Labor Dependency: Automation minimizes the need for direct human interaction in the closure phase, allowing personnel to focus on quality assurance and line management.

- Long-Term Reliability: The robust construction utilizing 304 SS Stainless Steel ensures machine durability and a long operational lifespan, reducing maintenance frequency and total cost of ownership.