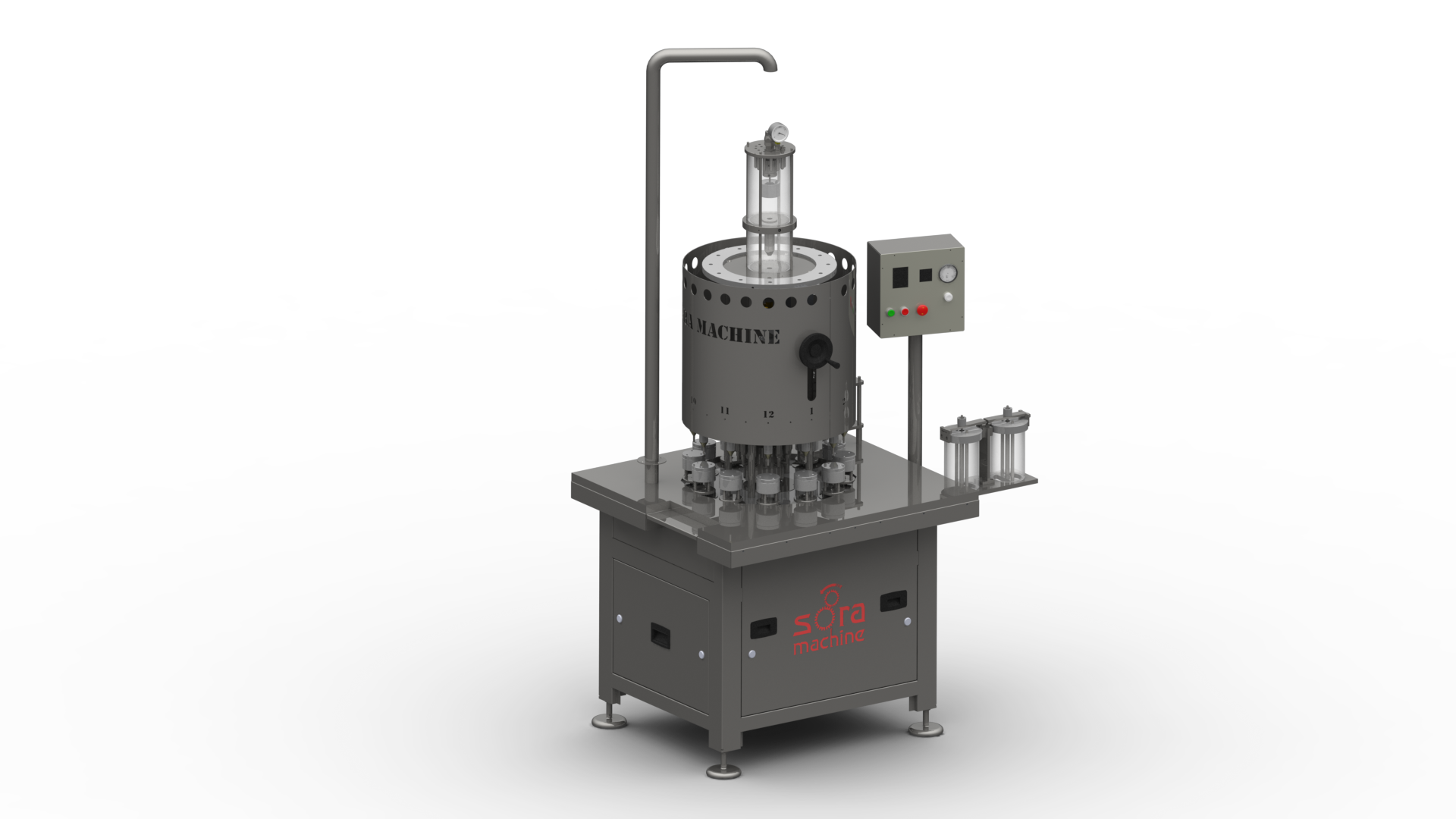

Rotary Perfume Filling Machine

The Rotary Perfume Filling Machine is a specialized, high-performance industrial solution engineered for the precise volumetric packaging of liquid products, particularly within the cosmetics and specialty chemical sectors. This 500 kg unit utilizes a synchronized 12-head filling mechanism to achieve a robust production output of 30–35 Bottles Per Minute (BPM). Designed for pharmaceutical-grade integrity, all product contact parts are constructed from premium SS 304L and SS 304 Stainless Steel. The system operates efficiently on a standard single-phase power supply (220-230v / 1 Ph / 0.4 kW), making it an energy-conscious choice for high-volume manufacturing environments.

Technical Advantages

The machine’s design integrates specific technical features optimized for stability, hygiene, and rapid production cycling:

- High Throughput Capability: Delivers a reliable production capacity of 30–35 BPM (Bottles Per Minute), suitable for sustained high-volume operations.

- Multi-Format Dosing: Equipped with 12 precision filling nozzles capable of handling a broad range of liquid volumes, from fine doses of 20 ml up to 200 ml.

- Material Compliance: Critical contact surfaces are manufactured using SS 304L and standard SS 304 Stainless Steel, ensuring chemical inertness, corrosion resistance, and compliance with strict sanitary requirements.

- Low Energy Profile: Requires minimal electrical input, operating efficiently on 220-230v / 1 Phase with an extremely low power draw of 0.4 kW.

- Pneumatic Requirement Specification: Requires an air supply of 20–30 CFM delivered at 6–7 kg bar to power the rotary indexing and control mechanisms reliably.

Used Technologies

The operation of this equipment relies on established technologies carefully integrated for efficiency and purity:

- Hygienic Material Engineering: The use of SS 304L/SS 304 Stainless Steel in all contact parts represents a key commitment to non-reactive, clean processing environments, essential for liquid media like perfumes and pharmaceuticals.

- Energy-Efficient Drive System: The low 0.4 kW power requirement suggests the integration of highly optimized electromechanical components, minimizing energy loss while sustaining the required torque for the 500 kg rotary mechanism.

- Optimized Pneumatic Control: The system utilizes specified compressed air (20–30 CFM @ 6–7 kg bar) to manage the precise indexing of the rotary table and the actuation of the 12 filling heads, guaranteeing consistent and repeatable cycle times.

Industrial Applications

Given its precision, sanitary construction, and variable volume capability, the Rotary Perfume Filling Machine is ideally suited for demanding packaging applications, often found in the industries serviced by Sora Machine, which include cosmetics, liquid filling, and pharmaceutical sectors:

- Cosmetics and Fragrance Manufacturing: Primary application for filling various sized perfume and cologne bottles (20 ml to 200 ml range).

- Specialty Liquid Packaging: Suitable for precise dosing of high-value or chemically sensitive liquids, such as essential oils or fine spirits.

- Pharmaceutical and Nutraceuticals: Adaptable for applications requiring strict hygiene and material non-contamination, owing to the extensive use of SS 304L/SS 304 contact materials.

Operational Benefits

Integrating this rotary system yields measurable operational advantages focused on throughput and cost reduction:

- Reduced Labor Overhead: The automated, high-speed rotary process allows for efficient operation with a minimal staffing requirement of only 1 to 2 personnel, significantly lowering long-term labor costs.

- Maximally Utilized Footprint: The rotary design provides high throughput (30–35 BPM) within a compact footprint (implied by the 500 kg weight), maximizing production density relative to available floor space.

- Flexibility in Product Lines: The ability to accurately fill small (20 ml) and medium (200 ml) volumes using the 12-head configuration minimizes downtime needed for product changeovers between various SKUs.

- Sustainability and Cost Control: The exceptionally low 0.4 kW power consumption directly translates into reduced utility costs and an improved environmental performance profile.

Differentiation from Competitors

The competitive edge of this Rotary Perfume Filling Machine is built upon its optimized utility-to-output ratio.

- Efficiency Metrics: While providing a robust output of 30–35 BPM with 12 filling heads, the system requires unusually low power (0.4 kW) and the operation of only 1–2 individuals. This efficiency profile reduces the TCO (Total Cost of Ownership) compared to machinery that demands higher energy loads or greater workforce dependency.

- Regulatory Assurance: The consistent specification of SS 304L for contact parts goes beyond standard industry minimums, offering enhanced resistance to highly corrosive media and ensuring compliance longevity in sensitive industrial applications.