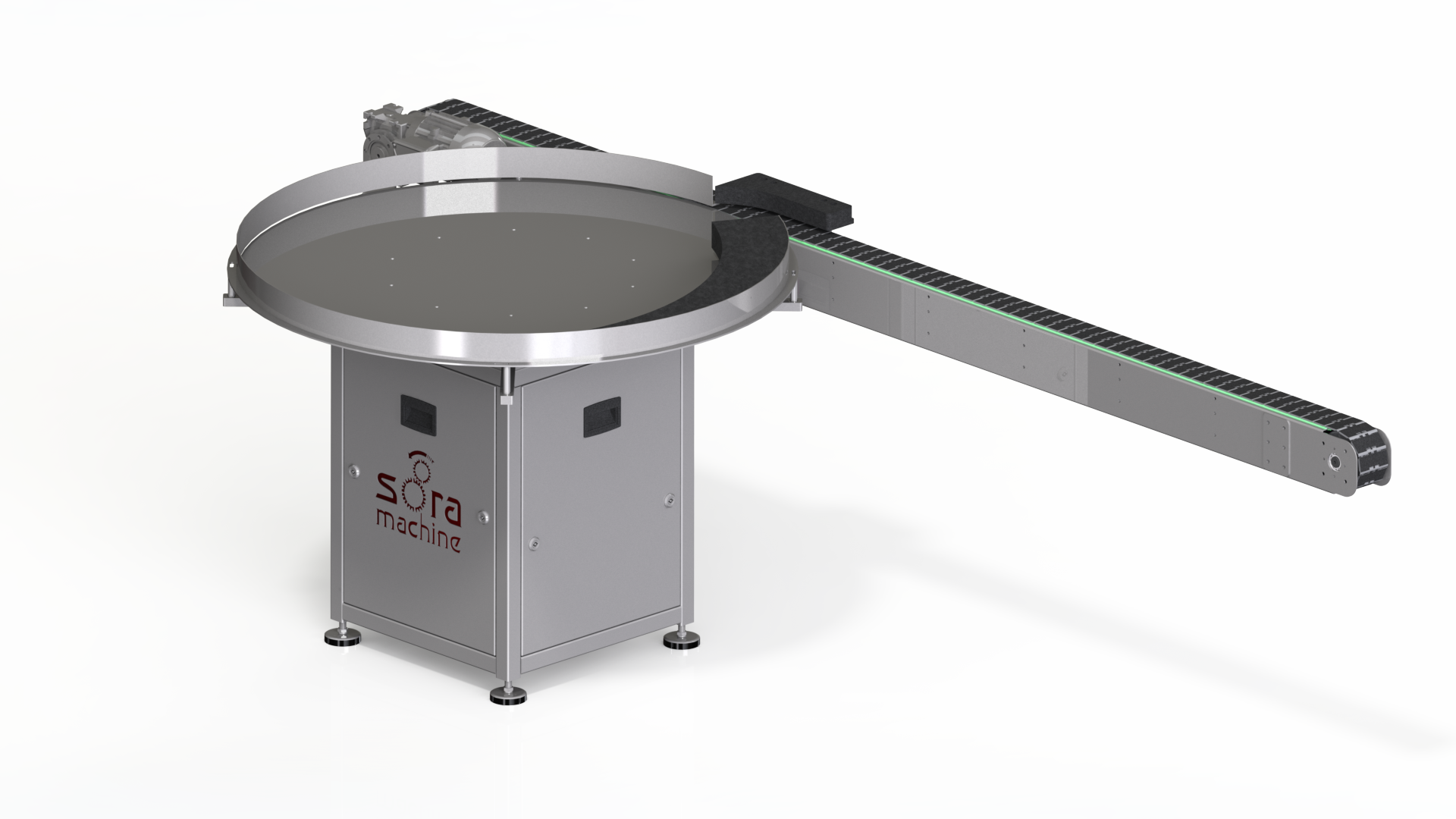

Rotative Collecting Table: High-Reliability Accumulation and Buffer Management

Rotative Collecting Table is a high-specification industrial component engineered for robust and reliable accumulation and buffering at the output of high-speed filling and packaging lines. Defined by its robust design and exceptional operational reliability, this unit utilizes an advanced gearbox drive system, ensuring precise motion control while eliminating the high-wear, high-maintenance components such as chains or belts. Built for longevity and hygiene, the table features a stainless steel frame and stainless steel top. Its design offers significant flexibility, allowing it to run a variety of round bottles. Key features like reversibility and adjustable height ensure seamless integration and optimized workflow management in demanding industrial environments.

Technical Advantages

The design of the Rotative Collecting Table incorporates several key mechanical and structural features that ensure superior performance and minimal upkeep:

- Advanced Drive System: Employs a gearbox drive mechanism, which inherently offers greater torque transmission and durability compared to systems relying on chains or belts, which are eliminated entirely.

- Component Protection: Critical mechanical and electrical components (motor, gearbox, and frame) are shielded by 4 stainless steel covers, providing exceptional defense against dust, moisture, and cleaning agents.

- Sanitary Construction: The unit features a Stainless steel top and a Stainless steel frame, adhering to strict hygiene standards and ensuring maximum resistance to corrosion.

- Precision Guidance: Containers are guided efficiently using a Stainless steel and poly rail mounted with L-bracket, ensuring stable collection and preventing product jams.

- Optimized Alignment: The Adjustable height feature allows technical personnel to rapidly align the collecting surface height with existing conveyors and downstream equipment.

- Bi-Directional Operation: The system is Reversible, offering crucial flexibility for production line flow or when required as a buffer for twin lines.

Employed Technologies

The Rotative Collecting Table relies on established industrial engineering technologies focused on resilience, longevity, and hygiene:

- Direct Gearbox Transmission: This technology is utilized to provide the rotational force for the table, prioritizing mechanical simplicity and reliability over high-wear alternatives like belts and chains.

- High-Grade Stainless Steel Fabrication: Extensive use of stainless steel is applied to the frame, top, and protective covers, meeting the sanitary and durability requirements typical of the Pharmaceutical and Cosmetics sectors.

- Modular Adjustment Mechanisms: The machine is designed for Easy to change over, incorporating simple, robust systems that allow rapid reconfiguration for different product formats (a variety of round bottles).

- Reversible Motor Control: The drive unit incorporates control logic that facilitates reversible motion, providing utility as both an accumulation and a feeding/buffer table.

Industrial Application Areas

The Rotative Collecting Table is an indispensable component for sectors requiring reliable, sanitary, and flexible container handling at the packaging line’s discharge point:

- Cosmetics Industry: Crucial for accumulating containers exiting processes like MASCARA FILLING UP TO 40 BPM.

- Pharmaceutical Sector: The Stainless steel construction and robust design meet high standards for sanitary handling.

- Liquid Filling Machines: Used to buffer containers before final labeling or case packing.

- Aerosol Filling Machines.

- Packing & Palletizing: Serves as a key accumulation point to manage the flow of containers into downstream packing equipment.

Operational Benefits

The robust technical design delivers substantial benefits to operational efficiency, maintenance schedules, and quality control:

- Maximized Uptime: By using a gearbox drive no chains or belts, unscheduled stops due to component failure or slippage are virtually eliminated, significantly increasing overall equipment effectiveness (OEE).

- Reduced Maintenance Costs: The elimination of chains and belts translates directly into lower part replacement inventory and reduced labor time dedicated to lubrication and tension adjustment.

- Versatile Production Capacity: The flexibility to handle a variety of round bottles combined with an Easy to change over mechanism allows for diverse production lines without requiring dedicated machinery.

- Extended Equipment Life: The 4 stainless steel covers protect the core motor and gearbox from corrosive agents and impact, ensuring a long operational life for the machine.

- Adaptability: The Reversible function and Adjustable height allow factory managers to swiftly reconfigure line layouts and integrate the table into existing production infrastructures without complex retrofitting.

Key Differentiators from Competitors

The Sora Machine Rotative Collecting Table stands out in the marketplace due to its focus on durability, maintenance reduction, and operational flexibility:

- Maintenance-Free Drive Integrity: The dedicated Gearbox drive no chains or belts is the primary differentiator, offering reliability and cleanliness superior to competing systems that rely on high-wear, messy chain or belt transmissions.

- Superior Component Protection: The inclusion of 4 stainless steel covers to cover motor, gearbox and frame demonstrates a commitment to safeguarding critical mechanics, which is often overlooked in standard industrial accumulation tables.

- Engineered Versatility: The unit is designed with intrinsic flexibility (Reversible, Adjustable height, Easy to change over), making it a highly adaptable asset capable of serving multiple functions across different product lines.

- Assurance of Partnership: Sora Machine is positioned as a solution partner, ensuring clients that their products are in good hands.